Abstract

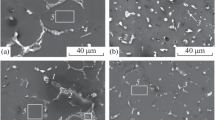

The effect of the introduction of additives of low-melting alloying elements in antifriction aluminum alloys on a change in the surface after tribological tests is estimated. Compositions are described and sample preparation is performed. For the study, a combination of electron microscopy methods (with elemental analysis) and probe microscopy (with the modes of spreading current and thermal-conductivity analysis) are used. It is shown that after heat treatment, the phase components acquire a globular shape in both alloys. Grain deformation, soft phase release to the surface, and mass transfer take place during the friction process. The hard phase components of the shoe material act as an abrasive, while mass transfer forms a film of secondary structures of variable thickness on the roller (under certain conditions, the film becomes thicker, which can lead to scuffing). The analysis of sections allows the presence of a near-surface layer (50–100 µm thick) with a modified structure to be established. The SPM method is used to establish that the thermal conductivity map at the micro level correlates with the electrical conductivity map. X-ray structural analysis of the surfaces carried out before and after tribological tests showed that the lattice spacing decreased, lattice deformation increased, and texture appeared.

Similar content being viewed by others

REFERENCES

B. N. Arzamasov, T. V. Solov’eva, S. A. Gerasimov et al., Handbook on Construction Materials (Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Moscow, 2005) [in Russian].

B. S. Ünlü and E. Atik, Mater. Des., No. 30, 1381 (2009). https://doi.org/10.1016/j.matdes.2008.06.069

A. E. Mironov, I. S. Gershman, A. V. Ovechkin, and E. I. Gershman, J. Frict. Wear 36, 257 (2015). https://doi.org/10.3103/S1068366615030095

N. A. Bushe, A. E. Mironov, and T. F. Markova, Zheleznye dorogi mira, No. 11, 44 (2003).

A. Mironov, P. Podrabinnik, and E. Kuznetsov, Mater. Today: Proc. 11 (Part 1), 197 (2019). https://doi.org/10.1016/j.matpr.2018.12.131

N. A. Belov, A. O. Mikhailina, A. N. Alabin, and O. O. Stolyarova, Met. Sci. Heat Treat. 58, 195 (2016). https://doi.org/10.1007/s11041-016-9988-5

N. A. Belov, O. O. Stolyarova, and A. O. Yakovleva, Russ. Metall. (Engl. Transl.) 2016, 198 (2016). https://doi.org/10.1134/S0036029516030034

B. Ya. Sachek, A. M. Mezrin, T. I. Muravyeva, et al., J. Frict. Wear 36, 103 (2015). https://doi.org/10.3103/S1068366615020142

B. Ya. Sachek, A. M. Mezrin, T. I. Muravyeva, and O. O. Stolyarova, J. Frict. Wear 37, 469 (2016). https://doi.org/10.3103/S1068366616050160

O. O. Stolyarova, T. I. Murav’eva, D. L. Zagorskii, and N. A. Belov, Fiz. Mezomekh., 19 (5), 105 (2016).

A. O. Yakovleva, N. A. Belov, T. A. Bazlova, and I. V. Shkalei, Phys. Met. Metallogr. 119, 35 (2018). https://doi.org/10.1134/S0031918X18010167

I. I. Kurbatkin and T. I. Murav’eva, Trenie Smazka Mash. Mekh., No. 1, 38 (2012).

I. G. Goryacheva, I. I. Kurbatkin, and N. A. Bushe, Zavod. Lab., Diagn. Mater. 74 (4), 51 (2008).

Metal Science: Textbook,vol. 2. Heat Treatment. Alloys, Ed. by V. S. Zolotorevskii (Mosk. Inst. Stali Splavov, Moscow, 2009) [in Russian].

O. O. Shcherbakova, T. I. Murav’eva, and D. L. Zagorskii, Pis’ma o Materialakh 8 (2), 123 (2018). https://doi.org/10.22226/2410-3535-2018-2-123-128

ACKNOWLEDGMENTS

We are grateful to Yu. Bobrov (NT-MDT, Zelenograd) for carrying out a part of the SPM measurements, A.M. Mezrin (Ishlinsky Institute for Problems in Mechanics, Russian Academy of Sciences) for performing the tribological tests.

Funding

The study was partially supported by a Grant of the President of the Russian Federation project no. MK-871.2018.8 № АААА-А18-118080290023-08 (sample preparation and microscopic studies), and the Russian Foundation for Basic Research, project no. 18-38-00289 mol_a (X-ray structural studies).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Semenova

Rights and permissions

About this article

Cite this article

Shcherbakova, O.O., Muravyeva, T.I., Shkalei, I.V. et al. Microscopic and X-Ray Analysis of the Surface Changes in Aluminum Alloys during Friction. J. Surf. Investig. 14, 830–840 (2020). https://doi.org/10.1134/S1027451020040333

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451020040333