Abstract

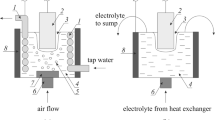

The process of reducing plasma-arc smelting of titanium raw materials from the Yarega deposit aimed at refining it from silicon has been studied. The smelting was performed in a water-cooled metal-graphite reactor, consisting of a copper cylindrical chamber with a diameter of 100 mm and a graphite bottom insert with a thickness of 30 mm serving as the anode of the arc. A hollow graphite cathode through the channel of which a mixture of quartz-leucoxene with graphite was supplied to the region of the anode spot was installed in the upper part of the chamber. In the course of quartz-leucoxene melting, silicon dioxide SiO2 contained therein was reduced to SiO with the evaporation thereof, thus enriching the melt in titanium. The arc power amounted to 13 kW. The experimentally measured parameters of the temperature field and the current density in the anode spot and in the arc column are in good agreement with the results of calculations made under the assumption that the arc occurring on the quartz-leucoxene anode acts as a heat source with approximately uniform heat flux density.

Similar content being viewed by others

REFERENCES

Sadykhov, G.B., New approaches to the use of complex titanium and other refractory materials in Russia, in Institut metallurgii i materialovedeniya im. A.A. Baikova RAN 75 let (Collection of Scientific Works Dedicated to the 75th Anniversary of the Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences), Moscow: Nauka, 2013, pp. 37–59.

Zanaveskin, K.L., Maslennikov, A.N., Makhin, M.N., and Zanaveskin, L.N., Peculiarities of chemical and mineralogical composition of rough quartz-leucoxene concentrate of Yarega ore deposit, Obogashch. Rud (S.-Peterburg), 2015, no. 5, pp. 25–32.

Nikolaev, A.V., Nikolaev, A.A., Kirpichev, D.E., and Samokhin, A.V., RF Patent 2586190, 2016.

Nikolaev, A.A., Kirpichev, D.E., Samokhin, A.V., and Nikolaev, A.V., Thermochemical plasma-arc treatment of leucoxene concentrate, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 3, pp. 406–411.

Nikolaev, A.A., Kirpichev, D.E., and Nikolaev, A.V., Energy characteristics of reducing plasma arc melting of leucoxene concentrate, Fiz. Khim. Obrab. Mater., 2017, no. 5, pp. 18–25.

Nikolaev, A.A., Kirpichyov, D.E., and Nikolaev, A.V., The energetic structure of plasma arc anode under reduction melting of quartz-leucoxene concentrate, Inorg. Mater. Appl. Res., 2019, vol. 10, no. 3, pp. 560–565.

Simonyan, L.M. and Kats, Ya.L., Measurement of the anode spot temperature of a plasma arc discharge, Russ. Metall. (Engl. Transl.), 2018, vol. 2018, no. 12, pp. 1147–1151.

Izluchatel’nye svoistva tverdykh materialov (Radiation Properties of Solid Materials), Sheidlin, A.E., Ed., Moscow: Energiya, 1974.

Gasik, M.I. and Lyakishev, N.P., Teoriya i tekhnologiya elektrometallurgii ferrosplavov (Theory and Technology of Production of Ferroalloys), Moscow: Intermet Inzhiniring, 1999.

Rykalin, N.N., Raschety teplovykh protsessov pri svarke (Calculations of Heat Processes during Welding), Moscow: Mashgiz, 1951.

Raizer, Y.P., Gas Discharge Physics, New York: Springer, 1991.

Kirpichev, D.E., Nikolaev, A.A., Nikolaev, A.V., and Tsvetkov, Yu.V., Morphological and chemical characteristics of iron obtained by liquid-phase plasma-arc reduction, Steel Transl., 2007, vol. 37, no. 9, pp. 780–783.

Funding

This work was financially supported according to state assignment no. 007-00129-18-00.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Nikolaev, A.A., Kirpichev, D.E. & Nikolaev, A.V. Thermophysical Parameters of the Anode Region of Plasma Arc under the Reduction Smelting of Quartz-Leucoxene Concentrate in a Metal-Graphite Reactor. Inorg. Mater. Appl. Res. 11, 563–567 (2020). https://doi.org/10.1134/S207511332003034X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332003034X