Abstract

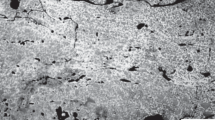

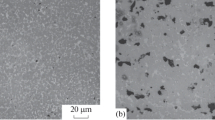

The effect of the pulsed laser irradiation in air on Cr23C6 ceramic with Cr3C2 and Cr7C3 additives has been studied. It is established that the main process occurring in the zone of laser radiation is the melting of the ceramic surface of chromium carbide and the formation of a crater. This process is accompanied by the ejection of melt droplets from the crater zone and the dissociation of chromium carbides. As a result, the crater area is enriched in such ablation products as Cr, C, CO, and CO2. Reduction of hydrogen in the crater zone and neighboring areas leads to slowing down of the rate of oxidation processes, and the presence of ablation products such as Cr and C atoms promotes the process of synthesis of oxycarbides CrxCyOz (x ≈ 0.3–0.8, y ≈ 0.03–0.3, z ≈ 0.61–0.26) in the gas phase. Emission of the newly formed products of ablation from the crater and their distribution to the neighboring areas is accompanied by coagulation of nanoparticles into clusters. Depending on the length of flight of nanoclusters through different temperature zones and temperature of the deposition surface, oxycarbides with different morphology are formed: from islets (like fractal clusters) to film ones. The deposited ablation products are characterized by the signs of particle size “separation.” This makes it possible to create films of a given type and purpose. The passage of particles of different sizes through a gaseous medium containing oxygen is accompanied by the oxidation of oxycarbides to Cr2O3.

Similar content being viewed by others

REFERENCES

Bannykh, O.A., Budberg, P.B., Alisova, S.P., et al., Diagrammy sostoyaniya dvoinykh i mnogokomponentnykh sistem na osnove zheleza (Diagrams of the State of Binary and Multicomponent Iron-Based Systems), Moscow: Metallurgiya, 1986.

Dvoinye i mnogokomponentnye sistemy na osnove medi (Cooper-Based Binary and Multicomponent Systems), Shukhardin, S.V., Ed., Moscow: Nauka, 1979.

Diagrammy sostoyaniya dvoinykh metallicheskikh sistem (Diagrams of the State of Binary Metal Systems), Lyakishev, N.P., Ed., in 3 vols., Moscow: Mashinostroenie, 1996–1997–2000.

Nygren, K., Andersson, M., Högström, J., Fredriksson, W., Edström, K., Nyholm, L., and Jansson, U., Influence of deposition temperature and amorphous carbon on microstructure and oxidation resistance of magnetron sputtered nanocomposite CrC films, Appl. Surf. Sci., 2014, vol. 305, pp. 143–153.

Aubert, A., Gillet, R., Gaucher, A., and Terrat, J.P., Hard chrome coatings deposited by physical vapor deposition, Thin Solid Films, 1983, vol. 104, pp. 165–172.

Ghadi, A., Soltanieh, M., Saghafian, H., and Yang, Z.G., Investigation of chromium and vanadium carbide composite coatings on CK45 steel by thermal reactive diffusion, Surf. Coat. Technol., 2016, vol. 289, pp. 1–10.

Mazumder, J., Laser assisted surface coatings, in Metallurgical and Ceramic Protective Coatings, Stern, K.H., Ed., London: Chapman and Hall, 1996, pp. 74–111.

Kim, T.H. and Kim, B.C., Chromium carbide laser-beam surface-alloying treatment on stainless steel, J. Mater. Sci., 1992, vol. 27, pp. 2967–2973.

Chen, J., Wang, S.-H., and Xue, L., On the development of microstructures and residual stresses during laser cladding and post-heat treatments, J. Mater. Sci., 2012, vol. 47, pp. 779–792.

Wu, S., Guo, B., Li, T., and Gui, D., Oxidation of chromium carbide coated Q235 steel in wet and dry air at 750°C, Constr. Build. Mater., 2015, vol. 81, pp. 11–14.

Venkatesh, L., Pitchuka, S.B., Sivakumar, G., Gundakaram, R.C., Joshi, S.V., and Samajdar, I., Microstructural response of various chromium carbide based coatings to erosion and nano impact testing, Wear, 2017, vols. 386–387, pp. 72–79.

Kagawa, A., Ohta, Y., and Nakayama, K., Mechanism of crack generation in carbide surface layer of laser-clad iron alloys, Mater. Trans., 2002, vol. 43, no. 6, pp. 1261–1265.

Pawlowski, L., Thick laser coatings: a review, J. Therm. Spray Technol., 1999, vol. 8, no. 2, pp. 279–295.

Du, B., Samant, A.N., Paital, S.R., and Dahotre, N.B., Pulsed laser synthesis of ceramic–metal composite coating on steel, J. Appl. Surf. Sci., 2008, vol. 255, pp. 3188–3194.

Caricato, A.P., Luches, A., Martino, M., Valerini, D., Kudryavtsev, Yu.V., Korduban, A.M., Mulenko, S.A., and Gorbachuk, N.T., Deposition of chromium oxide thin films with large thermoelectromotive force coefficient by reactive pulsed laser ablation, J. Optoelectron. Adv. Mater., 2010, vol. 12, pp. 427–431.

Polini, R., Barletta, M., Rubino, G., and Vesco, S., Recent advances in the deposition of diamond coatings on Co-cemented tungsten carbides, Adv. Mater. Sci. Eng., 2012, vol. 2012, art. ID 151629. https://doi.org/10.1155/2012/151629

Li, T., Lou, Q., Dong, J., Wei, Y., and Liu, J., Modified surface morphology in surface ablation of cobalt-cemented tungsten carbide with pulsed UV laser radiation, J. Appl. Surf. Sci., 2001, vol. 172, nos. 3–4, pp. 331–344.

Haytham, A.E., Hanadi, G.S., Taha, M.M., Ali, M.H., and Ehab, A.-R., Characterization of structures and properties of amorphous nanostructured SiC thin films deposited on AISI 304 stainless steel using pulsed laser deposition, Proc. Inst. Mech. Eng.,Part N, 2013, vol. 227, no. 4, pp. 199–207.

Kosolapova, T.Ya., Karbidy (Carbides), Moscow: Metallurgiya, 1968.

Douard, A., Maury, F., Jorcin, J.B., Pebere, N., Bonino, J.P., and Glenat, H., Reactivity of Cr(CO)6 in atmospheric pressure CVD processes for the growth of various metallurgical coatings, Rev. Adv. Mater. Sci., 2007, vol. 15, pp. 24–32.

Douard, A., Bernard, C., and Maury, F., Thermodynamic simulation of atmospheric DLI-CVD processes for the growth of chromium-based hard coatings using bis(benzene)chromium as molecular source, Surf. Coat. Technol., 2008, vol. 203, nos. 5–7, pp. 516–520.

Barbosa, D.C., Almeida, F.A., Silva, R.F., Ferreira, N.G., Trava-Airoldi, V.J., and Corat, E.J., Influence of substrate temperature on formation of ultrananocrystalline diamond films deposited by HFCVD argon-rich gas mixture, Diamond Relat. Mater., 2009, vol. 18, no. 10, pp. 1283–1288.

Zhou, D., Gruen, D.M., Qin, L.C., McCauley, T.G., and Krauss, A.R., Control of diamond film microstructure by Ar additions to CH4/H2 microwave plasmas, J. Appl. Phys., 1998, vol. 84, no. 4, pp. 1981–1989.

Yang, T.-S., Lai, J.-Y., Cheng, C.-L., and Wong, M.-S., Growth of faceted, ballas-like and nanocrystalline diamond films deposited in CH4/H2/Ar MPCVD, Diamond Relat. Mater., 2001, vol. 10, pp. 2161–2066.

Krauz, V.I., Martynenko, Yu.V., Svechnikov, N.Yu., Smirnov, V.P., Stankevich, V.G., and Khimchenko, L.N., Nanostructures in controlled thermonuclear fusion devices, Phys.-Usp., 2010, vol. 53, no. 10, pp. 1015–1038. https://doi.org/10.3367/UFNe.0180.201010c.1055

Budaev, V.P. and Khimchenko, L.N., Fractal structure of deposited nano-films in fusion device, Vopr. At. Nauki Tekh., Ser.: Termoyad. Sint., 2008, no. 3, pp. 34–61.

Fillit, R.Y., Maury, F., and Schuster, F., Structural characterization of chromium carbide coatings deposited by MOCVD: evidence for a cubic metastable CrC1 –x, Proc. Eight Int. Conf. on Ion and Plasma Assisted Techniques (IPAT-91). Brussels, London: CEP Consultants, 1991, pp. 50–55.

Zink, N., Therese, H.A., Pansiot, J., and Tremel, W., In situ heating TEM study of onion-like WS2 and MoS2 nanostructures obtained via MOCVD, Chem. Mater., 2008, vol. 20, no. 1, pp. 65–71.

Carta, G., Natali, M., Rosseto, G., Zanella, P., Salmaso, G., Restello, S., Rigato, V., Kaciulis, S., and Mezzi, A., A comparative study of Cr2O3 thin films obtained by MOCVD using three different precursors, Chem. Vap. Deposition, 2005, vol. 11, nos. 8–9, pp. 375–380.

Sun, S., Tompa, G.S., Rice, C.E., Sun, X.W., Lee, Z.S., Lien, S.C., Huang, C.W., Cheng, L.C., and Feng, Z.C., Metal organic chemical vapor deposition and investigation of ZnO thin films grown on sapphire, Thin Solid Films, 2008, vol. 516, no. 16, pp. 5571–5576.

Herman, I.P., Laser-assisted deposition of thin films from gas-phase and surface adsorbed molecules, Chem. Rev., 1989, vol. 89, no. 6, pp. 1323–1357.

Besling, W., Goossens, A., Meester, B., and Schoonman, J., Laser-induced chemical vapor deposition of nanostructured silicon carbonitride thin films, J. Appl. Phys., 1998, vol. 83, no. 1, pp. 544–553.

Nowak, R., Konstantinov, L., and Hess, P., Laser induced chemical vapor deposition of chromium films from chromium hexacarbonyl using a KrF excimer laser, Appl. Surf. Sci., 1989, vol. 36, pp. 177–184.

Sandana, V.E., Rogers, D.J., Hosseini Teherani, F., McClintock, R., Bayram, C., Razeghi, M., Drouhin, H.-J., Clochard, M.C., Sallet, V., Garry, G., and Falyouni, F., Comparison of ZnO nanostructures grown using pulsed laser deposition, metal organic chemical vapor deposition, and physical vapor transport, J. Vac. Sci. Technol., B: Microelectron. Nanometer Struct.–Process., Meas., Phenom., 2009, vol. 27, no. 3, pp. 1678–1683.

Douard, A. and Maury, F., Chromium-based coatings by atmospheric chemical vapor deposition at low temperature from Cr(CO)6, Surf. Coat. Technol., 2005, vol. 200, pp. 1407–1412.

Voitovich, R.F., Okislenie karbidov i nitridov (Oxidation of Carbides and Nitrides), Kiev: Naukova Dumka, 1981.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by K. Gumerov

Rights and permissions

About this article

Cite this article

Fironov, Y.S., Vlasova, M.V., Melnikov, I.V. et al. Formation of CrxCyOz Coatings under Laser Treatment of Chromium Carbide Ceramics. Inorg. Mater. Appl. Res. 11, 610–618 (2020). https://doi.org/10.1134/S2075113320030132

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320030132