Abstract

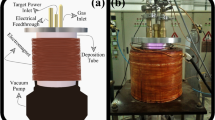

A particular YSZ feedstock for very low-pressure plasma spraying (VLPPS) has been designed which can be automatically divided into less than 5 μm YSZ molten particles in the long plasma jet. Fully molten particles were deposited on the substrate at different deposition distances of 250, 350 and 450 mm, respectively. The deposition behavior of less than 5 μm YSZ molten particles were studied aiming to obtain a thin gastight YSZ coating. The flattening ratio of particles at different deposition distances and the gas permeability of YSZ coating prepared by VLPPS were investigated. The results revealed that the thickness of flattened particles was about 0.10-0.35 μm and the flattening ratio of molten particles was about 4.7. The flattened particles were bonded well with substrates and the width of vertical cracks appeared in flattened particles was 0.01-0.02 μm. The gas permeability of coatings prepared at 350 mm was 1.5 × 10−7 cm4 (gf)−1 s−1.

Similar content being viewed by others

References

L. Bianchi, P. Lucchese, A. Denoirjean, and P. Fauchais, Zirconia Splat Formation and Resulting Coating Properties, 1995

C.C. Berndt, Thermal Spray: A United Forum for Scientific and Technological Advances, the 1st United Thermal Spray Conference, 1997

A. Kucuk, R.S. Lima, and C.C. Berndt, Influence of Plasma Spray Parameters on Formation and Morphology of ZrO2-8 wt% Y2O3 Deposits, J. Am. Ceram. Soc., 2001, 84(4), p 693-700

Y.-Z. Xing, C.-J. Li, Q. Zhang, C.-X. Li, and G.-J. Yang, Influence of Microstructure on the Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia Deposits, J. Am. Ceram. Soc., 2008, 91(12), p 3931-3936

C.-J. Li, G.-J. Yang, and C.-X. Li, Development of Particle Interface Bonding in Thermal Spray Coatings: A Review, J. Therm. Spray Technol., 2012, 22(2-3), p 192-206

C. Lamuta, G. Di Girolamo, and L. Pagnotta, Microstructural, Mechanical and Tribological Properties of Nanostructured YSZ Coatings Produced with Different APS Process Parameters, Ceram. Int., 2015, 41(7), p 8904-8914

A. Vardelle, C. Moreau, J. Akedo, H. Ashrafizadeh, C.C. Berndt, J.O. Berghaus, M. Boulos, J. Brogan, A.C. Bourtsalas, A. Dolatabadi, M. Dorfman, T.J. Eden, P. Fauchais, G. Fisher, F. Gaertner, M. Gindrat, R. Henne, M. Hyland, E. Irissou, E.H. Jordan, K.A. Khor, A. Killinger, Y.-C. Lau, C.-J. Li, L. Li, J. Longtin, N. Markocsan, P.J. Masset, J. Matejicek, G. Mauer, A. McDonald, J. Mostaghimi, S. Sampath, G. Schiller, K. Shinoda, M.F. Smith, A.A. Syed, N.J. Themelis, F.-L. Toma, J.P. Trelles, R. Vassen, and P. Vuoristo, The 2016 Thermal Spray Roadmap, J. Therm. Spray Technol., 2016, 25(8), p 1376-1440

C. Zhang, H.L. Liao, W.Y. Li, G. Zhang, C. Coddet, C.J. Li, C.X. Li, and X.J. Ning, Characterization of YSZ Solid Oxide Fuel Cells Electrolyte Deposited by Atmospheric Plasma Spraying and Low Pressure Plasma Spraying, J. Therm. Spray Technol., 2006, 15(4), p 598-603

G.-J. Yang, Z.-L. Chen, C.-X. Li, and C.-J. Li, Microstructural and Mechanical Property Evolutions of Plasma-Sprayed YSZ Coating During High-Temperature Exposure: Comparison Study Between 8YSZ and 20YSZ, J. Therm. Spray Technol., 2013, 22(8), p 1294-1302

H. Sun, Y. Chen, F. Chen, Y. Zhang, and M. Liu, High-Performance Solid Oxide Fuel Cells Based on a Thin La0.8Sr0.2Ga0.8Mg0.2O3 − δ Electrolyte Membrane Supported by a Nickel-Based Anode of Unique Architecture, J. Power Sources, 301, 199-203 (2016)

P. Alnegren, M. Sattari, J.-E. Svensson, and J. Froitzheim, Temperature Dependence of Corrosion of Ferritic Stainless Steel in Dual Atmosphere at 600-800 C, J. Power Sources, 2018, 392, p 129-138

S. Frangini, A. Masi, L.D. Seta, M. Bianco, and J. Van Herle, Composite Cu-LaFeO3Conversion Coatings on a 18Cr Ferritic Stainless Steel for IT-SOFC Interconnects: Effect of Long-Term Air Exposure at 700 C on Cr Diffusion Barrier and Electrical Properties, J. Electrochem. Soc., 2018, 165(2), p F97-F104

N.H. Menzler, D. Sebold, and O. Guillon, Post-Test Characterization of a Solid Oxide Fuel Cell Stack Operated for More Than 30,000 Hours: The Cell, J. Power Sources, 2018, 374, p 69-76

M. Bianco, J.P. Ouweltjes, and J. Van herle, Degradation Analysis of Commercial Interconnect Materials for Solid Oxide Fuel Cells in Stacks Operated up to 18000 HOURS, International Journal of Hydrogen Energy, 44(59), 31406-31422 (2019)

S. Lee, Y.-H. Jang, H.Y. Shin, K. Lee, M. Bae, J. Kang, and J. Bae, Reliable Sealing Design of Metal-Based Solid Oxide Fuel Cell Stacks for Transportation Applications, Int. J. Hydrogen Energy, 2019, 44(57), p 30280-30292

T.A. Prokop, K. Berent, M. Mozdzierz, J.S. Szmyd, and G. Brus, A Three-Dimensional Microstructure-Scale Simulation of a Solid Oxide Fuel Cell Anode—The Analysis of Stack Performance Enhancement After a Long-Term Operation, Energies, 2019, 12(24), p 4784

T. Zhu, X. Chen, W. Ni, Q. Zhong, and M. Han, Structural and Electrochemical Property Evolutions of Perovskite SOFC Anodes: Role of Fuel Atmosphere in (La0.4Sr0.6)1-Co0.2Fe0.7Nb0.1O3-δ, International Journal of Hydrogen Energy, 44(59), 31386-31393 (2019)

X. He, B. Meng, Y. Sun, B. Liu, and M. Li, Electron Beam Physical Vapor Deposition of YSZ Electrolyte Coatings for SOFCs, Appl. Surf. Sci., 2008, 254(22), p 7159-7164

Y.-Z. Xing, C.-J. Li, C.-X. Li, and G.-J. Yang, Influence of Through-Lamella Grain Growth on Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia as an Electrolyte in Solid Oxide Fuel Cells, J. Power Sources, 2008, 176(1), p 31-38

Z. Zheng, J. Luo, and Q. Li, Mechanism of Competitive Grain Growth in 8YSZ Splats Deposited by Plasma Spraying, J. Therm. Spray Technol., 2015, 24(5), p 885-891

C.-J. Li, X.-J. Ning, and C.-X. Li, Effect of Densification Processes on the Properties of Plasma-Sprayed YSZ Electrolyte Coatings for Solid Oxide Fuel Cells, Surf. Coat. Technol., 2005, 190(1), p 60-64

H. Tsukuda, A. Notomi, and N. Histatome, Application of Plasma Spraying to Tubular-Type Solid Oxide Fuel Cells Production, J. Therm. Spray Technol., 2000, 9(3), p 364-368

X.-J. Ning, C.-X. Li, C.-J. Li, G.-J. Yang, Effect of Powder Structure on Microstructure and Electrical Properties of Plasma-Sprayed 4.5 mol% YSZ coating, Vacuum, 80(11-12), 1261-1265 (2006)

R. Hui, Z. Wang, O. Kesler, L. Rose, J. Jankovic, S. Yick, R. Maric, and D. Ghosh, Thermal Plasma Spraying for SOFCs: Applications, Potential Advantages, and Challenges, J. Power Sources, 2007, 170(2), p 308-323

G. Bolelli, L. Lusvarghi, T. Varis, E. Turunen, M. Leoni, P. Scardi, C.L. Azanza-Ricardo, and M. Barletta, Residual Stresses in HVOF-Sprayed Ceramic Coatings, Surf. Coat. Technol., 2008, 202(19), p 4810-4819

J. Kiilakoski, R. Musalek, F. Lukac, H. Koivuluoto, and P. Vuoristo, Evaluating the Toughness of APS and HVOF-Sprayed Al2O3-ZrO2-COATINGS by In SITU- and Macroscopic Bending, J. Eur. Ceram. Soc., 2018, 38(4), p 1908-1918

E.-J. Yang, C.-J. Li, G.-J. Yang, C.-X. Li, and M. Takahashi, Effect of Intersplat Interface Bonding on the Microstructure of Plasma-Sprayed Al2O3 Coating, IOP Conference Series: Materials Science and Engineering, 2014, 61, p 012022

C.J. Li and W.Z. Wang, Quantitative Characterization of Lamellar Microstructure of Plasma-Sprayed Ceramic Coatings Through Visualization of Void Distribution, Mater. Sci. Eng., A, 2004, 386(1), p 10-19

T. Ide, T. Namikawa, and Y. Yamazaki, Preparation of 8 YSZ Thin Films on Porous LSM Substrates by Electron Beam Evaporation, 電気化学および工業物理化学: denki kagaku, 64, (1996)

Electron Beam Physical Vapor Deposition of YSZ Electrolyte Coatings for SOFCs, (Accessed 22 254)

M. Hartmanová, V. Nádaždy, F. Kundracik, and C. Mansilla, Influence of Deposition Conditions on Electrical and Mechanical Properties of Sm2O3-doped CeO2 Thin Films Prepared by EB-PVD (+IBAD) Methods. Part 1: Effective Relative Permittivity, Applied Surface Science, 269, 65-71 (2013)

Q.-Y. Chen, X.-Z. Peng, G.-J. Yang, C.-X. Li, and C.-J. Li, Characterization of Plasma Jet in Plasma Spray-Physical Vapor Deposition of YSZ Using a < 80 kW Shrouded Torch Based on Optical Emission Spectroscopy, J. Therm. Spray Technol., 2015, 24(6), p 1038-1045

G. Mauer and R. Vaßen, Plasma Spray-PVD: Plasma Characteristics and Impact on Coating Properties, J. Phys: Conf. Ser., 2012, 406, p 012005

L. Zhu, N. Zhang, B. Zhang, R. Bolot, H. Liao, and C. Coddet, In Situ Synthesis of FeAl Dense Coatings by Very Low Pressure Reactive Plasma Spraying, J. Therm. Spray Technol., 2012, 22(2-3), p 90-95

M. Goral, S. Kotowski, A. Nowotnik, M. Pytel, M. Drajewicz, and J. Sieniawski, PS-PVD Deposition of Thermal Barrier Coatings, Surf. Coat. Technol., 2013, 237, p 51-55

K. Iizuka, M. Kambara, and T. Yoshida, Growth of Tin Oxide Thick Films by Plasma Spray Physical Vapor Deposition, Sensors and Actuators B: Chemical, 2011, 155(2), p 551-556

D. Zhu, H.T. Lin, Y. Zhou, S. Widjaja, and D. Singh, Plasma Spray-Physical Vapor Deposition (PS-PVD) of Ceramics for Protective Coatings, John Wiley & Sons, Inc., 2011

G. Mauer, A. Hospach, and R. Vaßen, Process Development and Coating Characteristics of Plasma Spray-PVD, Surf. Coat. Technol., 2013, 220, p 219-224

C.-J. Li and J.-L. Li, Evaporated-Gas-Induced Splashing Model for Splat Formation During Plasma Spraying, Surf. Coat. Technol., 2004, 184(1), p 13-23

A.T.T. Tran, M.M. Hyland, T. Qiu, B. Withy, and B.J. James, Effects of Surface Chemistry on Splat Formation During Plasma Spraying, J. Therm. Spray Technol., 2008, 17(5-6), p. 637-645

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, and D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, Journal of Thermal Spray Technology, 4(1), 50-58

S. Brossard, P.R. Munroe, A.T.T. Tran, and M.M. Hyland, Study of the Splat Formation for Plasma Sprayed NiCr on Aluminum Substrate as a Function of Substrate Condition, Surf. Coat. Technol., 2010, 204(16-17), p 2647-2656

M. Mutter, G. Mauer, R. Mücke, O. Guillon, and R. Vaßen, Correlation of Splat Morphologies with Porosity and Residual Stress in Plasma-Sprayed YSZ Coatings, Surf. Coat. Technol., 2017, 318, p 157-169

P. Fauchais, M. Vardelle, and S. Goutier, Latest Researches Advances of Plasma Spraying: From Splat to Coating Formation, J. Therm. Spray Technol., 2016, 25(8), p 1534-1553

J.-J. Tian, S.-W. Yao, X.-T. Luo, C.-X. Li, and C.-J. Li, An Effective Approach for Creating Metallurgical Self-bonding in Plasma-Spraying of NiCr-Mo Coating by Designing Shell-Core-Structured Powders, Acta Mater., 2016, 110, p 19-30

X. Jiang and S. Sampath, Effect of Substrate Condition on Splat Formation During Thermal Spray Deposition, TMS Annual Meeting, 1998, 1998, p 439-448

S. Sampath, X.Y. Jiang, J. Matejicek, A.C. Leger, and A. Vardelle, Substrate Temperature Effects on Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings Part I: Case Study for Partially Stabilized Zirconia, Mater. Sci. Eng., A, 1999, 272(1), p 181-188

C. Delbos, J. Fazilleau, V. Rat, J.F. Coudert, P. Fauchais, and B. Pateyron, Phenomena Involved in Suspension Plasma Spraying Part 2: Zirconia Particle Treatment and Coating Formation, Plasma Chem. Plasma Process., 2006, 26(4), p 393-414

A. Joulia, G. Bolelli, E. Gualtieri, L. Lusvarghi, S. Valeri, M. Vardelle, S. Rossignol, and A. Vardelle, Comparing the Deposition Mechanisms in Suspension Plasma Spray (SPS) and Solution Precursor Plasma Spray (SPPS) Deposition of Yttria-Stabilised Zirconia (YSZ), J. Eur. Ceram. Soc., 2014, 34(15), p 3925-3940

C. Zhang, A.-F. Kanta, C.-X. Li, C.-J. Li, M.-P. Planche, H. Liao, and C. Coddet, Effect of In-Flight Particle Characteristics on the Coating Properties of Atmospheric Plasma-Sprayed 8 mol% Y2O3-ZrO2 Electrolyte Coating Studying by Artificial Neural Networks, Surf. Coat. Technol., 2009, 204(4), p 463-469

Y.Z. Xing, Y. Li, C.J. Li, C.X. Li, and G.J. Yang, Influence of Substrate Temperature on Microcracks Formation in Plasma-Sprayed Yttria-Stabilized Zirconia Splats, Key Eng. Mater., 2008, 373-374, p 69-72

L. Chen, G.-J. Yang, C.-X. Li, and C.-J. Li, Edge Effect on Crack Patterns in Thermally Sprayed Ceramic Splats, J. Therm. Spray Technol., 2016, 26(3), p 302-314

H. Xie, Y.-C. Xie, G.-J. Yang, C.-X. Li, and C.-J. Li, Modeling Thermal Conductivity of Thermally Sprayed Coatings with Intrasplat Cracks, J. Therm. Spray Technol., 2013, 22(8), p 1328-1336

L.I. Changjiu, A. Ohmori, and R. Mcpherson, The Relationship Between Microstructure and Young’s Modulus of Thermally Sprayed Ceramic Coatings, J. Mater. Sci., 1997, 32(4), p 997-1004

D. Waldbillig and O. Kesler, Effect of Suspension Plasma Spraying Process Parameters on YSZ Coating Microstructure and Permeability, Surf. Coat. Technol., 2011, 205(23-24), p 5483-5492

Acknowledgments

This work was supported by the National Key Research and Development Program of China (Basic Research Project, Grant No. 2017YFB0306100), the National Natural Science Foundation of China (Grant No. 91860114), and the National Key Research and Development Program of China (China-USA Intergovernmental Cooperation Project, Grant No. 2017YFE0105900).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, JT., Cheng, LX., Wang, YP. et al. Study on Deposition Behavior of Less Than 5 μm YSZ Particles in VLPPS. J Therm Spray Tech 29, 1708–1717 (2020). https://doi.org/10.1007/s11666-020-01087-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01087-6