Abstract

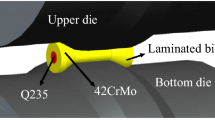

To further improve the comprehensive properties of 42CrMo/Q235 laminated shafts produced by cross wedge rolling, the heat treatment of the shafts was studied. Tensile and bending tests were carried out to compare the changes in mechanical properties before and after heat treatment. The results showed that the interfacial bonding strength increased most after tempering at 350 °C for 45 min. The microstructure of the interface was observed using a digital microscope. The results showed that the dispersed oxides on the interface were basically eliminated by using the scheme of tempering at 350 °C and holding for 45 min. The reasons for the change in mechanical properties were explained from the point of the interfacial microstructure. Scanning electron microscopy was used to analyze the micro-morphology of the tensile fracture. It was observed that after tempering at 350 °C and holding for 45 min, the dimple holes became larger and deeper, and the structure of fracture became more uniform and stable. From the point of the tensile fracture morphology, the reasons for the change in mechanical properties were explained as well.

Similar content being viewed by others

References

J. Li, H. Qian, B. Li, N.Y. Shen, Adv. Manuf. 3 (2015) 123–129.

D. Li, A.K. Ghosh, J. Mater. Process. Technol. 145 (2004) 281–293.

H. Yu, M. Xu, J. Zhao, Mech. Syst. Signal Process. 50–51 (2015) 548–562.

L.H. Dong, B.S. Xu, N. Xue, H.P. Wang, H.Y. Li, Adv. Manuf. 1 (2013) 91–96.

T. Torims, J. Vilcans, M. Zarins, V. Brutans, A. Ratkus, Adv. Mater. Res. 538–541 (2012) 1413–1421.

H. Hirahara, K. Yoshida, M. Iwase, in: 2010 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, IEEE, Montreal, ON, Canada, 2010, pp. 682–687.

Y.H. Mu, B.Y. Wang, J. Zhou, X. Huang, J.L. Li, J. Cent. South Univ. 25 (2018) 736–746.

X.B. Li, Journal of North University of China: Natural Science Edition 27 (2006) 365–368.

W.S. Hwang, T.I. Wu, W.C. Sung, J. Eng. Mater. Technol. 134 (2012) 014501.

H.T. Jiang, X.Q. Yan, J.X. Liu, X.G. Duan, Trans. Nonferrous Met. Soc. China 24 (2014) 697–704.

S.Y. Jiao, J.X. Dong, M.C. Zhang, L. Zheng, Mater. Rev. 23 (2009) No. 1, 59–62.

T.H. Yang, Mechanical property calculation and rolling composite process of aluminum-magnesium laminated composites, Nanjing University of Science and Technology, Nanjing, China, 2010.

L.L. Liang, Finite element simulation of the hot roll bonding process of TC4-6061 laminated composite, Yanshan University, Qinhuangdao, China, 2015.

M. Pozuelo, F. Carreño, M. Carsí, O.A. Ruano, Int. J. Mater. Res. 98 (2007) 47–52.

S. Nambu, M. Michiuchi, J. Inoue, T. Koseki, Compos. Sci. Technol. 69 (2009) 1936–1941.

W.F. Peng, J.H. Zhang, G.X. Huang, W.P. Liu, X.D. Shu, J. Zhu, Int. J. Adv. Manuf. Technol. 83 (2016) 145–155.

Z.J. Wu, W.F. Peng, X.D. Shu, Int. J. Adv. Manuf. Technol. 91 (2017) 517–526.

T.L. Zhang, Z.S. Ji, Z.H. Zhao, The Chinese Journal of Nonferrous Metals 23 (2013) 593–598.

Z.W. Feng, X.J. Mi, J.B. Wang, Z.S. Yuan, W.D. Miao, J. Zhou, The Chinese Journal of Nonferrous Metals 23 (2013) 756–764.

D. Lei, Y. Ren, X.R. Cheng, K. Lan, J. Qiu, D.J. Huang, Iron and Steel 52 (2017) No. 5, 66–71.

H.R. Jin, C.L. Zhang, X.Y. Han, Y.L. Yi, The Chinese Journal of Nonferrous Metals 25 (2015) 952–958.

Y.M. Zheng, Explosive welding and metal composite materials and their engineering applications, Central South University Press, Changsha, China, 2002.

Acknowledgements

This project was supported by the Fundamental Research Funds for the Provincial Universities of Zhejiang (No. SJLZ 2021002), the Natural Science Foundation of Zhejiang Province (Grant No. LY18E050006) and the Natural Science Foundation of Ningbo City (Grant No. 2017A610088), and the Ningbo Science and Technology Innovation 2025 Major Project (2018B10004, 2019B10100) and National Natural Science Foundation of China (Grant No. 51405248). The authors would like to gratefully acknowledge the support of K.C. Wong Magna Fund in Ningbo University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, S., Peng, Wf. & Shu, Xd. Effect of tempering on bonding characteristics of cross wedge rolling 42CrMo/Q235 laminated shafts. J. Iron Steel Res. Int. 27, 1170–1178 (2020). https://doi.org/10.1007/s42243-020-00488-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00488-9