Abstract

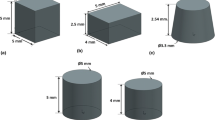

Finite strain deformation behaviour of recycled aluminium alloy AA6061 is investigated in this paper via uniaxial tensile test and Taylor cylinder impact test implementations. The uniaxial tensile tests are performed at different elevated temperature from 100 to 300 °C, at the strain rate of 10−4 s−1 and 10−3 s−1 and the Taylor cylinder impact tests are conducted at different impact velocity ranging from 170 to 370 m/s. The deformation behaviour of tensile test specimen is evaluated in term of the stress–strain curve and the anisotropic behaviour, including fracture mode, of the impact test specimen, is analyzed according to the geometric profile of the deformed specimen. Besides, the damage characteristic of both the experimental tests is characterized using Scanning Electron Microscope analysis and ImageJ software analysis. The recycled AA6061 exhibits strain-rate dependency behaviour and strong anisotropic behaviour. The flow stress and damage evolution are enhanced with the increment in strain rate. The anisotropic behaviour of such recycled material can be observed in the deformed specimen of impact test, where a non-symmetrical (ellipse shape) footprint is observed. Moreover, the damage is initiated in the undeformed specimen and it getting severe when a deformation is applied. This is due to the growth and coalescence of the micro-voids in the material resulting in formation of micro-cracks and dimples and increase in number of micro-voids.

Graphic Abstract

Similar content being viewed by others

References

M.W.A. Rashid, F.F. Yacob, M.A. Lajis, M.A. A.M. Abid, E.M.T. Ito, A review: the potential of powder metallurgy in recycling aluminum chips (Al 6061 & Al 7075). in Conference: 24th Design Engineering Systems Division JSME Conference Japan Society of Mechanical Engineers, 2014, pp. 14–27

S.-H. Hong, D.-W. Lee, B.-K. Kim, Manufacturing of aluminum flake powder from foil scrap by dry ball milling process. J. Mater. Process. Technol. 100, 105–109 (2000)

S. Kumar, F. Mathieux, G. Onwubolu, V. Chandra, A novel powder metallurgy-based method for the recycling of aluminum adapted to a small Island developing state in the Pacific. Int. J. Environ. Conscious Des. 13(3, 4), 1–22 (2007)

M. Rahimian, N. Ehsani, N. Parvin, H. Reza Baharvandi, The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 209(14), 5387–5393 (2009)

M. Rahimian, N. Parvin, N. Ehsani, The effect of production parameters on microstructure and wear resistance of powder metallurgy Al–Al2O3 composite. Mater. Des. 32(2), 1031–1038 (2011)

B.L. Chan, M.A. Lajis, Direct recycling of aluminium 6061 chip through cold compression. Int. J. Eng. Technol. 15(04), 4–8 (2015)

Y. Kume, T. Takahashi, M. Kobashi, N. Kanetake, Solid state recycling of die-cast aluminum alloy chip wastes by compressive torsion processing. Keikinzoku/J. Jpn. Inst. Light Met. 59(7), 354–358 (2009)

A. Ahmad, M.A. Lajis, N.K. Yusuf, S. Shamsudin, Z.W. Zhong, Parametric optimisation of heat treated recycling aluminium (AA6061) by response surface methodology. AIP Conf. Proc. 1885(1), 1–7 (2017)

S.N.A. Rahim, M.A. Lajis, S. Ariffin, Effect of extrusion speed and temperature on hot extrusion process of 6061 aluminum alloy chip. ARPN J. Eng. Appl. Sci. 11(4), 2272–2277 (2016)

M. Haase, A.E. Tekkaya, Recycling of aluminum chips by hot extrusion with subsequent cold extrusion. Procedia Eng. 81, 652–657 (2014)

A.E. Tekkaya, M. Schikorra, D. Becker, D. Biermann, N. Hammer, K. Pantke, Hot profile extrusion of AA-6060 aluminum chips. J. Mater. Process. Technol. 209(7), 3343–3350 (2009)

S.S. Khamis, M.A. Lajis, R.A.O. Albert, A sustainable direct recycling of aluminum chip (AA6061) in hot press forging employing response surface methodology. Procedia CIRP 26, 477–481 (2015)

N.K. Yusuf, M.A. Lajis, M.I. Daud, M.Z. Noh, Effect of operating temperature on direct recycling aluminium chips (AA6061) in hot press forging process. Appl. Mech. Mater. 315, 728–732 (2013)

N.K. Yusuf, M.A. Lajis, A. Ahmad, Hot press as a sustainable direct recycling technique of aluminium: mechanical properties and surface integrity. Materials (Basel) 10(8), 902 (2017)

A. Ahmad, M.A. Lajis, N.K. Yusuf, On the role of processing parameters in producing recycled aluminum AA6061 based metal matrix. Materials (Basel) 10(1098), 1–15 (2017)

A.L. Noradila, Z. Sajuri, J. Syarif, Y. Miyashita, Y. Mutoh, Effect of strain rates on tensile and work hardening properties for Al–Zn magnesium alloys. Int. J. Mater. Eng. Innov. 5(1), 28–37 (2014)

C.S. Ho, M.A.A. Rani, M.K.M. Nor, N. Ma, M.T.H. Sultan, M.A. Lajis, N.K. Yusuf, Characterization of anisotropic damage behaviour of recycled aluminium alloys AA6061 undergoing high velocity impact. Int. J. Integr. Eng. 11(1), 247–256 (2019)

T. A. I. De Vusyt, Hydrocode of Modelling of Water Impact, PhD. Thesis, School of Engineering, Cranfield University, 2003, pp. 214

M.K.M. Nor, N. Ma’at, C.S. Ho, M.S.A. Samad, An anisotropic deformation analysis of orthotropic materials subjected to high velocity impacts. Int. J. Mech. Mechatron. Eng. 17(5), 156–172 (2017)

A. Gavrus, H. Francillette, An Anisotropic Behaviour Analysis of AA2024 Aluminium Alloy Undergoing Large Plastic Deformations (InTech Open, London, 2011, pp. 49–68)

M.K.M. Nor, R. Vignjevic, J. Campbell, Modelling of shockwave propagation in orthotropic materials. Appl. Mech. Mater. 315, 557–561 (2013)

S. Castagne, A. Habraken, S. Cescotto, Application of a damage model to an aluminium alloy. J. Damage Mech. 12(1), 5–30 (2003)

N. Ma’at, K.A. Kamarudin, A.E. Ismail, Implementation of finite strain-based constitutive formulation in LLLNL-DYNA3D to predict shockwave propagation in commercial aluminum alloys AA7010. Int. Eng. Res. Innov. Symp. 160(1), 012023 (2016)

M.K.M. Nor, Modelling inelastic behaviour of orthotropic metals in a unique alignment of deviatoric plane within the stress space. Int. J. Non-Linear Mech. 87, 43–57 (2016)

V. Panov, Modelling of behaviour of metals at high strain rates. Ph.D. Thesis, Cranfield University, 2006

Y. Wicaksana, S. Jeon, Strain rate effect on the crack initiation stress level under uniaxial compression, in 9th Asian Rock Mechanics Symposium, 2016, pp. 1–9

M.K.M. Nor, I.M. Suhaimi, Effects of temperature and strain rate on commercial aluminum alloy AA5083. Appl. Mech. Mater. 660, 332–336 (2016)

S.K.Y. Alaric, Material Characterization of Recycled Aluminium Alloy (AA6061) Undergoing Finite Strain Deformation (Universiti Tun Hussein Onn Malaysia, Parit Raja, 2017)

C.A. Acosta, C. Hernandez, A. Maranon, Validation of material constitutive parameters for the AISI 1010 steel from Taylor impact tests. Mater. Des. 110, 324–331 (2016)

Z. Cao, Investigation of Taylor impact test of isotropic and anisotropic material through geometrical characteristics of specimens. Degree of Master Thesis, University of Alabama, 2010

K.G. Rakvåg, T. Børvik, O.S. Hopperstad, A numerical study on the deformation and fracture modes of steel projectiles during Taylor bar impact tests. Int. J. Solids Struct. 51(3–4), 808–821 (2014)

K.G. Rakvåg, T. Børvik, I. Westermann, O.S. Hopperstad, An experimental study on the deformation and fracture modes of steel projectiles during impact. Mater. Des. 51, 242–256 (2013)

M.A.A. Rani, Characterization of Anisotropic Damage Behaviour of Recycled AA6061 Aluminium Alloys Undergoing High Velocity Impact (Universiti Tun Hussein Onn Malaysia, Parit Raja, 2018)

F.N.A. Janudin, Insight into Anisotropic-Damage Behaviour Including Fracture Mode of Recycled Aluminium Alloy AA6061 Reinforced with Alumina Oxide (Al2O3) Using Taylor Impact Test (Universiti Tun Hussein Onn Malaysia, Parit Raja, 2019)

R. Bobbili, V. Madhu, A.K. Gogia, Tensile behaviour of aluminium 7017 alloy at various temperatures and strain rates. J. Mater. Res. Technol. 5(2), 190–197 (2016)

N.A. Latif, Z. Sajuri, J. Syarif, Effect of tensile strain rates on flow stress for extruded AZ31 and AZ61 magnesium alloys. Int. J. Automot. Mech. Eng. 14(1), 3812–3823 (2017)

N. Ma’at, M.K.M. Nor, C.S. Ho, Effects of temperature and strain rate on the mechanical behaviour of commercial aluminium alloy AA6061. J. Adv. Res. Fluid Mech. Therm. Sci. 54(1), 21–26 (2019)

G. Wypych, Recycling, in Handbook of Material Weathering, 6th ed., (ChemTec Publishing, 2018), 892 p

A.I. Selmy, A.M. El-Gohry, M.I.A. El Aal, M.A. Taha, Characteristics of solid state recycling of aluminum alloy (AA6061) chips by hot extrusion. Int. Conf. Eng. Sci. Appl. 1, 316–323 (2016)

A.I. Selmy, M.I.A. El Aal, A.M. El-Gohry, M.A. Taha, Solid-state recycling of aluminum alloy (AA-6061) chips via hot extrusion followed by equal channel angular pressing (ECAP). Egypt. Int. J. Eng. Sci. Technol. 21(10), 33–42 (2016)

Z. Zheng, X. Zhang, L. Xie, L. Huang, T. Sun, Changes of microstructures and mechanical properties in commercially pure titanium after different cycles of proposed multi-directional forging. Metal 9(2), 175–186 (2019)

M.F.A. Ibrahim, S.R.S. Bakar, A. Jalar, N.K. Othman, J. Sharif, A.R. Daud, N.M. Rashdi, Effect of porosity on tensile behaviour of welded AA6061-T6 aluminium alloy. Appl. Mech. Mater. 66–68, 534–539 (2011)

Acknowledgements

Authors wish to convey sincere gratitude to Universiti Tun Hussein Onn Malaysia (UTHM) for providing the financial means during the preparation to complete this work under Geran Penyelidikan Pascasiswazah (GPPS), Vot U74 and UTHM Contract Research Grant, Vot H276. This research work is also supported by the Aerospace Manufacturing Research Center (AMRC), Faculty of Engineering, Universiti Putra Malaysia and the Sustainable Manufacturing and Recycling Technology, Advanced Manufacturing and Material Center (SMART AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ho, C.S., Mohd Nor, M.K. An Experimental Investigation on the Deformation Behaviour of Recycled Aluminium Alloy AA6061 Undergoing Finite Strain Deformation. Met. Mater. Int. 27, 4967–4983 (2021). https://doi.org/10.1007/s12540-020-00858-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00858-8