Abstract

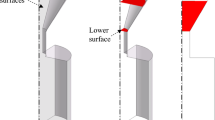

The dripping zone of the blast furnace is important in determining the productivity and quality of hot metal. The permeability of the bed affects both of these factors. Static holdup of hot metal and slag resulting from interfacial phenomena adversely affect the permeability of the bed. To characterize the holdup in the packed bed, we assumed the packed bed as an ensemble of two-sphere contacts at various contact axis inclinations and for contact angles. We developed mathematical models to determine the shapes of stable films at these contacts taking into account interfacial and gravitational energies. The film at higher contact angles shows an asymmetric shape even in between vertical spheres, which is investigated in detail. We also show the reason for the difficulty for dripping of the liquids at smaller particle sizes.

Similar content being viewed by others

Notes

It is found through various weighing or draining techniques that static liquid holdup is independent of gas flow and liquid flow rates. However, these experimental techniques require shutting down of the liquid and gas flow in order to measure the static and dynamic holdups of liquid. It may be possible that the static liquid holdup at the operating condition (which is of primary interest) is different than the one after shutting down of the reactor as drag forces of the fluids may play a crucial effect. These data are not reported and, hence, need rigorous experiments. Various tracer techniques have been employed to calculate the static liquid holdup in the operating condition.[42,43,44] However, most of the studies show large discrepancies in data due to various assumptions incorporated in the tracer technique studies. Therefore, until now, the static liquid holdup is extensively measured after stopping the liquid and gas flow and it is assumed to be approximately the same in the operating condition. Thus, assumptions of static liquid holdup being independent of the upward gas flow rate and liquid flow rate remain justified.

This is the flooding one obtains in the absence of upward gas flow. Flooding phenomenon is strongly dependent on the pressure drop, upward gas flow rate, and void fraction in the bed. The void fraction in the bed, in turn, depends on the total liquid holdup in the bed. The total holdup increases very sharply with the gas flow rate near the flooding limit. As static holdup is independent of the gas flow rate mainly, dynamic liquid holdup increases with the increasing gas flow rate. This formulation is unable to model the dynamic liquid holdup and the effect of upward gas flow rate on it. Therefore, actual flooding phenomena cannot be calculated through this model.

References

M. Sasaki, K. Ono, A. Suzuki, Y. Okuno, and K. Yoshizawa: Trans. ISIJ, 1977, vol. 17, pp. 391–400.

H.L. Shulman, C.F. Ullrich, A.Z. Proulx, and J. Zimmerman: AIChE J., 1955, vol. 1, pp. 253–58.

J. Yagi: ISIJ Int., 1993, vol. 33, pp. 619–39.

W. Xiong, X.-G. Bi, G.-Q. Wang, and F. Yang: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 562–70.

A.R. Hanstead: Master’s Dissertation, McGill University, Montreal, PQ, Canada, 2000.

Z.S. Mao, T.Y. Xiong, and J. Chen: Chem. Eng. Sci., 1993, vol. 48, pp. 2697–2703.

A.E. Sáez and R.G. Carbonell: J. Colloid Interface Sci., 1990, vol. 140, pp. 408–18.

A.E. Sáez, M.M. Yépez, C. Cabrera, and E.M. Soria: AIChE J., 1991, vol. 37, pp. 1733–36.

T. Fukutake and V. Rajakumar: Trans. ISIJ, 1982, vol. 22, pp. 355–65.

W.M. Husslage, M.A. Reuter, R.H. Heerema, T. Bakker, and A.G.S. Steeghs: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 765–76.

H. Kawabata, Z. Liu, F. Fujita, and T. Usui: ISIJ Int., 2005, vol. 45, pp. 1466–73.

V. Sahajwalla, R. Khanna, and A.S. Mehta: Metall. Mater. Trans. B, 2007, vol. 35B, pp. 75–83.

E. Kapilashrami, V. Sahajwalla, and S. Seetharaman: ISIJ Int., 2004, vol. 44, pp. 653–59.

H. Towers: Trans. J. Br. Ceram. Soc., 1954, vol. 53, pp. 180–202.

Z. Yan, X. Lv, Z. Pang, X. Lv, and C. Bai: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1322–30.

H.L. Shulman, C.F. Ullrich, and N. Wells: AIChE J., 1955, vol. 1, pp. 247–53.

G.C. Gardner: Chem. Eng. Sci., 1956, vol. 5, pp. 101–13.

N. Standish: Chem. Eng. Sci., 1968, vol. 23, pp. 945–47.

G.J. Kramer: Chem. Eng. Sci., 1998, vol. 53, pp. 2985–92.

D. Megias-Alguacil and L.J. Gauckler: AIChE J., 2009, vol. 55, pp. 1103–09.

D.N. Mazzone, G.I. Tardos, and R. Pfeffer: J. Coll. Interface Sci., 1986, vol. 113, pp. 544–56.

S. Ghosh, N.N. Viswanathan, and N.B. Ballal: Chem. Eng. Sci., 2020, vol. 212, pp. 115332–40.

P.J. Mackey and N.A. Warner: Metall. Trans. B, 1972, vol. 3, pp. 1807–16.

P.J. Mackey and N.A. Warner: Chem. Eng. Sci., 1973, vol. 28, pp. 2141–54.

G.S. Gupta, J.D. Litster, E.T. White, and V.R. Rudolph: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 597–604.

D. Jang, M. Shin, J.S. Oh, H.-S. Kim, S.H. Yi, and J. Lee: ISIJ Int., 2014, vol. 54, pp. 1251–55.

H.L. George, R.J. Longbottom, S.J. Chew, D.J. Pinson, and B.J. Monaghan: ISIJ Int., 2014, vol. 54, pp. 1790–96.

H.L. George, R.J. Longbottom, S.J. Chew, and B.J. Monaghan: ISIJ Int., 2014, vol. 54, pp. 820–26.

L.H. George, B.J. Monaghan, R. Longbottom, and P.R. Austin: ISIJ Int., 2011, vol. 53, pp. 1172–79.

D.D. Geleta, I.H. Siddiqui, and J. Lee: Metall. Mater. Trans. B, 2020, vol. 51, pp. 102–13.

S.D. Iliev: Comput. Methods Appl. Mech. Eng., 1995, vol. 126, pp. 251–65.

T. Young: Philos. Trans. R. Soc. London, 1805, vol. 95, pp. 65–87.

C. Geuzaine and J.-F. Remacle: Int. J. Numer. Meth. Eng., 2009, vol. 79, pp. 1309–31.

GNU Team: GNU Scientific Library, 2008.

C. Dobrzynski and P. Frey: in Proceedings of the 17th International Meshing Roundtable, Springer, Berlin, Heidelberg, 2008, pp. 177–94.

E. Akhilandeshwari, S. Ghosh, N.N. Viswanathan, and N.B. Ballal: in Advances in Process Metallurgy, Bangalore, India, 2019, pp. 276–80.

E. Kapilashrami, A. Jakobsson, A.K. Lahiri, and S. Seetharaman: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 193–99.

G.A. Turner and G.F. Hewitt: Trans. Inst. Chem. Eng., 1959, vol. 37, pp. 329–24.

W. Du, N. Quan, P. Lu, J. Xu, and W. Wei: Chem. Eng. Res. Des., 2015, vol. 106, pp. 115–25.

G. Mason and W. Clark: Nature, 1965, vol. 207, p. 512.

S.J. Chew, G.X. Wang, A.B. Yu, and P. Zulli: Ironmak. Steelmak., 1997, vol. 24 (5), pp. 392–400.

J.G. Schwartz, E. Weger, and M.P. Duduković: AIChE J., 1976, vol. 22, pp. 894–904.

V.S. Patwardhan and V.R. Shrotri: Chem. Eng. Commun., 1981, vol. 10, pp. 349–55.

C.N. Schubert, J.R. Lindner, and R.M. Kelly: AIChE J., 1986, vol. 32, pp. 1920–23.

Acknowledgments

The authors acknowledge Ms. Akhilandeswari, formerly graduate student, MEMS, IIT Bombay, and Ms. Manoja Namadi, presently at MTech, MEMS, IIT Bombay, for helping to carry out the required experiments. The authors also acknowledge the funding from DST for the cluster Dendrite and SpaceTime supercomputing facility, IIT Bombay, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 30, 2020.

Rights and permissions

About this article

Cite this article

Ghosh, S., Ballal, N.B. & Viswanathan, N.N. Fundamental Insight into the Dripping Criteria of Slag and Hot Metal in a Coke Bed Using Energy Minimization Model. Metall Mater Trans B 51, 2829–2842 (2020). https://doi.org/10.1007/s11663-020-01943-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01943-4