Abstract

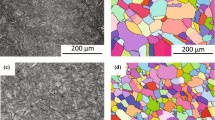

Discontinuous dynamic recrystallization (DDRX), which involves multiple nucleation and grain growth processes, plays a crucial role in grain refinement; however, the underlying mechanism and the significant role of twin boundaries (TBs) remain poorly understood. Here, the evolution of characteristic microstructures and the fraction and density of TBs under different deformation conditions (i.e., 1050–1200 °C, 0.001–1 s−1) in Incoloy 825 was investigated through a thermomechanical simulator, electron backscattered diffraction (EBSD), and transmission electron microscopy (TEM). The first strand of recrystallized grains nucleated along the original grain boundaries (GBs), separated by the newly formed random high-angle grain boundaries (HAGBs), which were transformed from low-angle grain boundaries (LAGBs) and pre-existing TBs. Subsequently, straight TBs forming in the new grains increased the misorientation angle, promoting the migration of stagnated grain boundaries, and parts of newly generated twinning chains at the front of the recrystallization zone converted into random HAGBs, providing sites for the following layer of nucleation. Moreover, triple junctions between the recrystallized and deformed grains also served as potential nucleation sites when the LAGBs in the large misorientation gradient were transformed into random HAGBs. Quantitative relationships between the recrystallized grain size and TB density were obtained.

Similar content being viewed by others

References

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 3rd ed., Pergamon Press, Oxford, 2017

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post–Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater Sci., 2014, 60, p 130–207

T. Sakai and J.J. Jonas, Dynamic Recrystallization: Mechanical And Microstructural Considerations, Acta Metall., 1984, 32, p 189–209

J.J. Jonas, C.M. Sellars, and W.J. McG, Tegart, Strength and Structure Under Hot–Working Conditions, Metall Rev., 1969, 14, p 1–24

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett, Current Issues in Recrystallization: A Review, Mater. Sci. Eng., A, 1997, 238, p 219–274

K. Huang and R.E. Logé, A Review of Dynamic Recrystallization Phenomena in Metallic Materials, Mater. Des., 2016, 111, p 548–574

K. Huang, K. Marthinsen, Q.L. Zhao, and R.E. Logé, The Double–Edge Effect of Second–Phase Particles on the Recrystallization Behaviour and Associated Mechanical Properties of Metallic Materials, Prog. Mater Sci., 2018, 92, p 284–359

Y. Zhang, N.R. Tao, and K. Lu, Effects of Stacking Fault Energy, Strain Rate and Temperature on Microstructure and Strength of Nanostructured Cu–Al Alloys Subjected to Plastic Deformation, Acta Mater., 2011, 59, p 6048–6058

F.I. Grace and M.C. Inman, Influence of Stacking Fault Energy on Dislocation Configurations in Shock–Deformed Metals, Metallography, 1970, 3(1), p 89–98

D. Ponge and G. Gottstein, Necklace Formation During Dynamic Recrystallization: Mechanisms and Impact on Flow Behavior, Acta Mater., 1998, 46, p 69–88

D.F. Li, Q.M. Guo, S.L. Guo, H.J. Peng, and Z.G. Wu, The Microstructure Evolution and Nucleation Mechanisms of Dynamic Recrystallization in Hot–Deformed Inconel 625 Superalloy, Mater. Des., 2011, 32, p 696–705

B. Wang, S.H. Zhang, M. Cheng, and H.W. Song, Dynamic Recrystallization Mechanism of Inconel 690 Superalloy During Hot deformation at High Strain Rate, J. Mater. Eng. Perform., 2013, 22, p 2382–2388

N. Dudova, A. Belyakov, T. Sakai, and R. Kaibyshev, Dynamic Recrystallization Mechanisms Operating in a Ni–20% Cr Alloy Under Hot–to–Warm Working, Acta Mater., 2010, 58, p 3624–3632

A. Chaudhuri, A. Sarkar, R. Kapoor, J.K. Chakravartty, R.K. Ray, and S. Suwas, Understanding the Mechanism of Dynamic Recrystallization During High-Temperature Deformation in Nb-1Zr-0.1C alloy, J. Mater. Eng. Perform., 2019, 28, p 448–462

X.T. Zhong, L. Wang, and F. Liu, Study on Formation Mechanism of Necklace Structure in Discontinuous Dynamic Recrystallization of Incoloy 028, Acta Metall. Sin., 2018, 54(7), p 969–980

H. Miura, T. Sakai, S. Andiarwanto, and J.J. Jonas, Nucleation of dynamic Recrystallization at Triple Junctions in Polycrystalline Copper, Philos. Mag., 2005, 85(23), p 2653–2669

S.Q. Zhu, H.G. Yan, X.Z. Liao, S.J. Moody, G. Sha, Y.Z. Wu, and S.P. Ringer, Mechanisms for Enhanced Plasticity in Magnesium Alloys, Acta Mater., 2015, 82, p 344–355

M. Azarbarmas, M. Aghaie-Khafri, A.M. Cabrera, and J. Calvo, Dynamic Recrystallization Mechanisms and Twining Evolution During Hot Deformation of Inconel 718, Mater. Sci. Eng. A, 2016, 678, p 137–152

A. Belyakov, H. Miura, and T. Sakai, Dynamic Recrystallization Under Warm Deformation of Polycrystalline Copper, ISIJ Int., 1998, 38, p 595–601

H. Miura, T. Sakai, R. Mogawa, and J.J. Jonas, Nucleation of Dynamic Recrystallization and Variant Selection in Copper Bicrystals, Philos Mag., 2007, 87, p 4197–4209

A.M. Wusatowska-Sarnek, H. Miura, and T. Sakai, Nucleation and Microtexture Development Under Dynamic Recrystallization of Copper, Mater. Sci. Eng. A, 2002, 323, p 177–186

H. Miura, T. Sakai, R. Mogawa, and G. Gottstein, Nucleation of Dynamic Recrystallization at Grain Boundaries in Copper Bicrystals, Scr. Mater., 2004, 51, p 671–675

H. Beladi, P. Cizek, and P.D. Hodgson, Dynamic Recrystallization of Austenite in Ni–30 pct Fe Model Alloy Microstructure and Texture Evolution, Metall. Mater. Trans. A, 2009, 40, p 1175–1189

E. Brunger, X. Wang, and G. Gottstein, Nucleation Mechanisms of Dynamic Recrystallization in Austenitic Steel Alloy 800H, Scr. Mater., 1998, 38(12), p 1843–1849

S. Mandal, A.K. Bhaduri, and V.S. Sarma, Role of Twinning on Dynamic Recrystallization and Microstructure During Moderate to High Strain Rate Hot Deformation of a Ti–Modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2012, 43, p 2056–2068

D.G. Cram, H.S. Zurob, Y.J.M. Brechet, and C.R. Hutchinson, Modelling Discontinuous Dynamic Recrystallization Using a Physically Based Model for Nucleation, Acta Mater., 2009, 57, p 5218–5228

R. Ding and Z.X. Guo, Coupled Quantitative Simulation of Microstructural Evolution and Plastic Flow During Dynamic Recrystallization, Acta Mater., 2001, 49, p 3163–3175

C. Sommitsch and W. Mitter, On Modelling of Dynamic Recrystallization of FCC Materials with Low Stacking Fault Energy, Acta Mater., 2006, 54, p 357–375

P. Bernard, S. Bag, K. Huang, and R.E. Loge, A Two-Site Mean Field Model of Discontinuous Dynamic Recrystallization, Mater. Sci. Eng. A, 2011, 528, p 7357–7367

G.B. Shan, Y.Z. Chen, Y.J. Li, C.Y. Zhang, H. Dong, Y.B. Cong, W.X. Zhang, L.K. Huang, and F. Liu, High Temperature Creep Resistance of a Thermally Stable Nanocrystalline Fe-5 at.%, Scr. Mater., 2020, 179, p 1–5

A. Momeni, G.R. Ebrahimi, M. Jahazi, and P. Bocher, Microstructure Evolution at the Onset of Discontinuous Dynamic Recrystallization: A Physics-Based Model of Sub-Grain Critical Size, J. Alloys Compd., 2014, 587, p 199–210

O. Beltran, K. Huang, and R.E. Logé, A Mean Field Model of Dynamic and Post-Dynamic Recrystallization Predicting kinetics, Grain Size and Flow Stress, Comput. Mater. Sci., 2015, 102, p 293–303

Y. Huang and F.J. Humphreys, Measurements of Grain Boundary Mobility During Recrystallization of a Single-Phase Aluminum Alloy, Acta Mater., 1999, 47, p 2259–2268

G. Gottstein, D.A. Molodov, L.S. Shvindlerman, D.J. Srolovitz, and M. Winning, Grain Boundary Migration: Misorientation Dependence, Curr. Opin. Solid State Mater. Sci., 2001, 5, p 9–14

V. Randle, Twinning-Related Grain Boundary Engineering, Acta Mater., 2004, 52, p 4067–4081

H. Jiang, J.X. Dong, M.C. Zhang, and Z.H. Yao, Evolution of Twins and Substructures During Low Strain Rate Hot Deformation and Contribution to Dynamic Recrystallization in Alloy 617B, Mater. Sci. Eng. A, 2016, 649, p 369–381

F.C. Liu and T.W. Nelson, Twining and Dynamic Recrystallization in Austenitic Alloy 718 During Friction Welding, Mater. Charact., 2018, 140, p 39–44

D.P. Field, L.T. Bradford, M.M. Nowell, and T.M. Lillo, The Role of Annealing Twins During Recrystallization of Cu, Acta Mater., 2007, 55(12), p 4233–4241

G.R. Ebrahimi, A. Momeni, H.R. Ezatpour, M. Jahazid, and P. Bocherd, Dynamic Recrystallization in Monel400 Ni–Cu Alloy: Mechanism and Role of Twinning, Mater. Sci. Eng. A, 2019, 744, p 376–385

D.G. Brandon, The Structure of High-Angle Grain Boundaries, Acta Metall., 1966, 14(11), p 1479–1484

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George, Microstructure Evolution and Critical Stress for Twinning in the CrMnFeCoNi High-Entropy Alloy, Acta Mater., 2016, 118, p 152–163

S. Sahu, P.C. Yadav, and S. Shekhar, Use of Hot Rolling for Generating Low Deviation Twins and a Disconnected Random Boundary Network in Inconel 600 Alloy, Metall. Mater. Trans. A, 2018, 49, p 628–643

X.T. Zhong, L. Wang, L.K. Huang, and F. Liu, Transition of Dynamic Recrystallization Mechanism During Hot Deformation of Incoloy 028 Alloy, J. Mater. Sci. Technol., 2020, 42, p 241–253

L. Wang, F. Liu, Q. Zuo, J.J. Cheng, and C.F. Chen, Processing Map and Mechanism of Hot Deformation of a Corrosion-Resistant Nickel-Based Alloy, J. Mater. Eng. Perform., 2017, 26, p 392–406

C.S. Pande, M.A. Imam, and B.B. Rath, Study of Annealing Twins in FCC Metals and Alloys, Metall. Trans. A, 1990, 21(11), p 2891–2896

N. Bozzolo, N. Souaï, and R.E. Logé, Evolution of Microstructure and Twin Density During Thermomechanical Processing in a γ-γ’ Nickel-Based Superalloy, Acta Mater., 2012, 60(13–14), p 5056–5066

Y. Jin, B. Lin, M. Bernacki, G.S. Rohrer, A.D. Rollett, and N. Bozzolo, Annealing Twin Development During Recrystallization and Grain Growth in Pure Nickel, Mater. Sci. Eng., A, 2014, 597, p 295–303

Z.G. Li, L.T. Zhang, N.R. Sun, Y.L. Sun, and A.D. Shan, Effects of Prior Deformation and Annealing Process on Microstructure and Annealing Twin Density in a Nickel-Based Alloy, Mater. Charact., 2014, 95, p 299–306

X.T. Zhong, L.K. Huang, L. Wang, and F. Liu, A Discontinuous Dynamic Recrystallization Model Incorporating the Characteristics of Initial Microstructure, T. Nonferr. Metal. Soc., 2018, 28, p 2294–2306

Acknowledgments

This work was supported by the National Key R&D Program of China (Grant Numbers 2017YFB0703001, 2017YFB0305100); the Natural Science Foundation of China (Grant Numbers 51790481, 51901185); the Fundamental Research Funds for the Central Universities (Grant Number 3102017jc01002); and the Natural Science Foundation of Shaanxi Province (Grant Number 2020JQ-153). We would like to thank the Analytical & Testing Center of Northwestern Polytechnical University for EBSD and TEM experiments.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhong, X., Huang, L. & Liu, F. Discontinuous Dynamic Recrystallization Mechanism and Twinning Evolution during Hot Deformation of Incoloy 825. J. of Materi Eng and Perform 29, 6155–6169 (2020). https://doi.org/10.1007/s11665-020-05093-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05093-1