Abstract

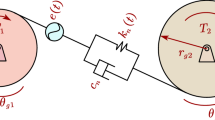

The topography of gear meshing interfaces is one of the key factors affecting the dynamic characteristics of the gear transmission system. In order to obtain the contact characteristics of meshing gear pair with different surface micro-topographies, an interface feature model and a tribo-dynamics coupling model for the gear system are proposed in this paper. The effects of the gear tooth surface micro-topography on the oil film distribution, contact damping and friction are considered. The time-varying meshing stiffness and the static transmission error are included in the abovementioned models. An exemplary gear pair is analyzed using the proposed models to investigate the influence of the surface micro-topography on the dynamic characteristics of gear system under different micro-topographies and input torque conditions. Simulation results show that the effects of gear tooth micro-topography on the gear dynamic responses (including the friction and the vicious damping at the gear meshing interface and the vibration in the direction of offline of action) are highly dependent on the regularity of tooth surface. The vibration and noise can be significantly controlled by manufacturing a regular gear tooth profiles instead of random profiles.

摘要

齿轮啮合面微观形貌是影响齿轮传动系统动力学特性的重要原因之一。本文建立了一个包含啮 合面啮合特性和摩擦动力学的耦合模型,旨在研究具有不同齿面微观形貌的齿轮动力学特性。该模型 考虑了齿面形貌对啮合面间润滑油膜厚度分布、接触阻尼以及摩擦力的影响,同时考虑了时变啮合刚 度和静传递误差等激励元素。以一对齿轮副为研究对象,利用该模型研究了不同齿面微观形貌但相同 齿面粗糙度以及不同负载工况下该齿轮副的动力学行为。仿真结果表明,齿面微观形貌的几何规则度 直接影响齿轮动力学响应(啮合面间的摩擦力,黏性阻尼以及摩擦力方向的振动)。通过加工更规则(而 非随机)的齿面能有效降低齿轮系统的振动和噪音。

Similar content being viewed by others

References

CAO Zheng, CHEN Zai-gang, JIANG Han-jun. Nonlinear dynamics of a spur gear pair with force-dependent mesh stiffness [J]. Nonlinear Dynamics, 2020, 99(2): 1227–1241. DOI: https://doi.org/10.1007/s11071-019-05348-0.

MA Hui, PANG Xu, FENG Ran-jiao, SONG Rong-ze, WEN Bang-chun. Fault features analysis of cracked gear considering the effects of the extended tooth contact [J]. Engineering Failure Analysis, 2015, 48: 105–120. DOI: https://doi.org/10.1016/j.engfailanal.2014.11.018.

MA Hui, LI Zhan-wei, FENG Meng-jiao, FENG Ran-jiao, WEN Bang-chun. Time-varying mesh stiffness calculation of spur gears with spalling defect [J]. Engineering Failure Analysis, 2016, 66: 166–176. DOI: https://doi.org/10.1016/j.engfailanal.2016.04.025.

YU Wen-nian, SHAO Yi-min, MECHEFSKE C K. The effects of spur gear tooth spatial crack propagation on gear mesh stiffness [J]. Engineering Failure Analysis, 2015, 54: 103–119. DOI: https://doi.org/10.1016/j.engfailanal.2015.04.013.

YU Wen-nian, MECHEFSKE C K. Analytical modeling of spur gear corner contact effects [J]. Mechanism and Machine Theory, 2016, 96: 146–164. DOI: https://doi.org/10.1016/j.mechmachtheory.2015.10.001.

YU Wen-nian, MECHEFSKE C K. A new model for the single mesh stiffness calculation of helical gears using the slicing principle [J]. Iranian Journal of Science and Technology: Transactions of Mechanical Engineering, 2019, 43(1): 503–515. DOI: https://doi.org/10.1007/s40997-018-0173-x.

SUN Yan-ning, MA Hui, HUANGFU Yi-fan, CHEN Kang-kang, CHE Lin-yang, WEN Bang-chun. A revised time-varying mesh stiffness model of spur gear pairs with tooth modifications [J]. Mechanism and Machine Theory, 129: 261–278. DOI: https://doi.org/10.1016/j.mechmachtheory.2018.08.003.

CAO Zheng, SHAO Yi-min, RAO Meng, YU Wen-nian. Effects of the gear eccentricities on the dynamic performance of a planetary gear set [J]. Nonlinear Dynamics, 2018, 91: 1–15. DOI: https://doi.org/10.1007/s11071-017-3738-0.

CHEN Zai-gang, ZHAI Wan-ming, WANG Kai-yun. Vibration feature evolution of locomotive with tooth root crack propagation of gear transmission system [J]. Mechanical Systems and Signal Processing, 2019, 115: 29–44. DOI: https://doi.org/10.1016/j.ymssp.2018.05.038.

MA Hui, ZENG Jin, FENG Ran-jiao, PANG Xu, WANG Qi-bin, WEN Bang-chun. Review on dynamics of cracked gear systems [J]. Engineering Failure Analysis, 2015, 55: 224–245. DOI: https://doi.org/10.1016/j.engfailanal.2015.06.004.

YU Wen-nian, MECHEFSKE C K, TIMUSK M. The dynamic coupling behaviour of a cylindrical geared rotor system subjected to gear eccentricities [J]. Mechanism and Machine Theory, 2017, 107: 105–122. DOI: https://doi.org/10.1016/j.mechmachtheory.2016.09.017.

YU Wen-nian, MECHEFSKE C K, TIMUSK M. Effects of tooth plastic inclination deformation due to spatial cracks on the dynamic features of a gear system [J]. Nonlinear Dynamics, 2017, 87: 2643–2659. DOI: https://doi.org/10.1007/s11071-016-3218-y.

LIANG Xi-hui, ZUO Ming-jian, FENG Zhi-peng. Dynamic modeling of gearbox faults: A review [J]. Mechanical System and Signal Processing, 2018, 98: 852–876. DOI: https://doi.org/10.1016/j.ymssp.2017.05.024.

LARSSON R. Transient non-Newtonian elastohydrodynamic lubrication analysis of an involute spur gear [J]. Wear, 1997, 207(1, 2): 67–73. DOI: https://doi.org/10.1016/S0043-1648(96)07484-4.

HU Yuan-zhong, WANG Hui, WANG Wen-zhong, ZHU Dong. A computer model of mixed lubrication in point contacts [J]. Tribology International, 2001, 34(1): 65–73. DOI: https://doi.org/10.1016/S0301-679X(00)00139-0.

LI Sheng, KAHRAMAN A. A tribo-dynamic model of a spur gear pair [J]. Journal of Sound and Vibration, 2013, 332(20): 4963–4978. DOI: https://doi.org/10.1016/j.jsv.2013.04.022.

LI Sheng. A thermal tribo-dynamic mechanical power loss model for spur gear pairs [J]. Tribology International, 2015, 88: 170–178. DOI: https://doi.org/10.1016/j.triboint.2015.03.022.

OUYANG T, HUANG Hao-zhong, ZHANG Ning, MO Chun-lan, CHEN Nan. A model to predict tribo-dynamic performance of a spur gear pair [J]. Tribology International, 2017, 116: 449–459. DOI: https://doi.org/10.1016/j.triboint.2017.08.005.

SHI Xiu-jiang, SUN Wen, LU Xi-qun, MA Xuan, ZHU Dong, ZHAO Bin, HE Tao. Three-dimensional mixed lubrication analysis of spur gears with machined roughness [J]. Tribology International, 2019, 140: 105864. DOI: https://doi.org/10.1016/j.triboint.2019.105864.

LIU He-li, LIU Huai-ju, ZHU Cai-chao, SUN Zhang-dong, BAI Hou-yi. Study on contact fatigue of a wind turbine gear pair considering surface roughness [J]. Friction, 2020, 8(3): 553–567. DOI: https://doi.org/10.1007/s40544-019-0297-z.

YU Wen-nian, MECHEFSKE C K, TIMUSK M. Influence of the addendum modification on spur gear back-side mesh stiffness and dynamics [J]. Journal of Sound and Vibration, 2017, 389: 183–201. DOI: https://doi.org/10.1016/j.jsv.2016.11.030.

CHEN Zai-gang, SHAO Yi-min. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth [J]. Engineering Failure Analysis, 2011, 18(8): 2149–2164. DOI: https://doi.org/10.1016/j.engfailanal.2011.07.006.

YU Wen-nian, MECHEFSKE C K, TIMUSK M. A new dynamic model of a cylindrical gear pair with localized spalling defects [J]. Nonlinear Dynamics, 2018, 91(4): 2077–2095. DOI: https://doi.org/10.1007/s11071-017-4003-2.

YANG D C H, SUN Z S. A rotary model for spur gear dynamics [J]. Journal of Mechanisms, Transmissions, and Automation in Design, 1985, 107(4): 529–535. DOI: https://doi.org/10.1115/1.3260759.

BOU-CHAKRA E, CAYER-BARRIOZ J, MAZUYER D, JARNIAS F, BOUFFET A. A non-Newtonian model based on Ree-Eyring theory and surface effect to predict friction in elastohydrodynamic lubrication [J]. Tribology International, 2010, 43(9): 1674–1682. DOI: https://doi.org/10.1016/j.triboint.2010.03.016.

LI Sheng, KAHRAMAN A. Prediction of spur gear mechanical power losses using a transient elastohydrodynamic lubrication model [J]. Tribology Transactions, 2010, 53(4): 554–563. DOI: https://doi.org/10.1080/10402000903502279.

CHEN W W, LIU S B, WANG Q J. Fast Fourier transform based numerical methods for elasto-plastic contacts of nominally flat surfaces [J]. Journal of Applied Mechanics, Transactions ASME, 2008, 75(1): 011022. DOI: https://doi.org/10.1115/1.2755158.

WU Shi-feng, CHENG H S. A friction model of partial-EHL contacts and its application to power loss in spur gears [J]. Tribology Transactions, 1991, 34(3): 398–407. DOI: https://doi.org/10.1080/10402009108982050.

LAI W T, CHENG H S. Temperature analysis in lubricated simple sliding rough contacts [J]. ASLE transactions, 1985, 28(3): 303–312. DOI: https://doi.org/10.1080/05698198508981625.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51905053, 51805051) supported by the National Natural Science Foundation of China; Project(cstc2019jcyj-bshX0119) supported by the Chongqing Postdoctoral Science Foundation, China

Rights and permissions

About this article

Cite this article

Yin, L., Deng, Cl., Yu, Wn. et al. Dynamic characteristics of gear system under different micro-topographies with the same roughness on tooth surface. J. Cent. South Univ. 27, 2311–2323 (2020). https://doi.org/10.1007/s11771-020-4451-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4451-6