Abstract

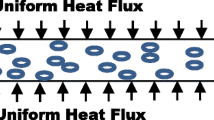

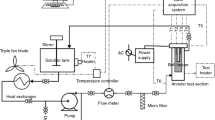

As far as design safety and operation of heat exchangers with a horizontal flow are concerned, it is necessary to study local heat transfer coefficient, boiling pressure drop, and critical heat flux for flow in a horizontal tube. In the present experimental work, local axial distribution of heat transfer coefficient, two-phase pressure drop, and critical heat flux for the flow boiling in a horizontal straight tube with R-123 as working fluid has been studied. Experiments are performed in horizontal tubes of diameter 11.9 mm and wall thickness 0.4 mm of SS304, having a heated length of 400 mm, 600 mm, and 1000 mm for the mass flux of 180 to 1210 kg/m2s. The local wall temperature is measured using the Infra-Red thermal imaging technique. The local heat transfer coefficients are compared with six different well-known correlations. Also, the two-phase frictional pressure drop is measured and compared with eight different general correlations. In the present study, a sudden rise in wall temperature at any location of a test section is considered as the occurrence of a boiling crisis. The boiling crisis mechanism observed in the present study is of departure from nucleate boiling (DNB). It takes place in the subcooled, or low quality saturated boiling region and in-between the length of the test sections rather than at exit as in the dry-out type of CHF. The critical heat flux is compared with six different predictive correlations. The mechanism of occurrence of CHF in the present work is found to be a departure from nucleate boiling.

Similar content being viewed by others

Abbreviations

- Cp :

-

Specific heat at constant pressure J/kgK.

- d :

-

Tube diameter m

- f :

-

Friction factor Dimensionless

- G :

-

Mass flux kg/m2s

- g :

-

Acceleration due to gravity m2/s

- h :

-

Heat transfer coefficient W/m2K

- h* :

-

Fully developed subcooled heat transfer coefficient W/m2K

- h f :

-

Enthalpy of sensible heat J/kg

- h fg :

-

Enthalpy of latent heat J/kg

- I :

-

Current A

- k :

-

Thermal conductivity W/mK

- L, l :

-

Length m

- LCC :

-

Local condition correlation Dimensionless

- \( \dot{m} \) , :

-

Mass flow rate kg/s

- P :

-

Pressure N/m2

- p :

-

Perimeter m

- P r :

-

Reduced Pressure (Psys / Pcr) Dimensionless

- Q ′ :

-

Heat supply W

- r :

-

Radius m

- q ′ ′:

-

Heat flux W/m2

- T :

-

Temperature °C

- UCC :

-

Upstream condition correlation Dimensionless

- V :

-

Voltage V

- X :

-

Lockhart Martinelli Parameter (for turbulent-turbulent flow) \( {X}_{tt}={\left(\frac{1-x}{x}\right)}^{0.9}{\left(\frac{\rho_g}{\rho_l}\right)}^{0.5}{\left(\frac{\mu_l}{\mu_g}\right)}^{0.1} \)

- x :

-

Quality of vapor Dimensionless

- α :

-

Void fraction Dimensionless

- ɸ :

-

Two-phase flow multiplier ∅2 = ∆PTP, fric/∆PSP Dimensionless

- μ :

-

Dynamic viscosity N s/m2

- ρ :

-

Density kg/m3

- σ :

-

Surface tension N/m

- acc:

-

Acceleration

- amb:

-

Ambient

- b :

-

Bulk

- cal :

-

Calculated

- conv :

-

Convection

- cr :

-

Critical

- e :

-

Exit

- E :

-

Effective

- exp :

-

Experimental

- f :

-

Liquid

- fg :

-

Liquid to vapor

- fric :

-

friction

- g :

-

Vapor

- H :

-

Horizontal position

- h :

-

Heated

- i, in :

-

Inlet, inner

- l :

-

Liquid

- loc :

-

Local

- o, out :

-

Outer

- sat :

-

Saturated

- SP :

-

Single-phase

- SC :

-

Sub-cooled

- sys :

-

System

- TP :

-

(Two-phase)

- tt :

-

Turbulent liquid and Turbulent vapor

- lt :

-

Laminar liquid and Turbulent vapor

- V :

-

Vertical position

- w :

-

Wall

- W :

-

Wetted

- CHF :

-

Critical heat flux

- DNB :

-

Departure from nucleate boiling

- HTC :

-

Heat transfer coefficient

- Co :

-

Convection number\( \kern0.5em Co={\left(\frac{1-x}{x}\right)}^{0.8}{\left(\frac{\rho_g}{\rho_l}\right)}^{0.5} \)

- Bo :

-

Boiling number Bo = q" /G hfg

- Ja :

-

Jakob number Ja = Cp(Tsat − Tin)/hfg

- Nu :

-

Nusselt number Nu = h d/k

- Pr :

-

Prandtl number Pr = μ Cp/k

- Re :

-

Reynolds number Re = G d/μ

- We :

-

Weber number WeL = G2L/ρ σ, Wed = G2d/ρ σ

References

Collier JG and Thome JR (1994) Convective boiling and condensation. Clarendon Press

Kandlikar SG (1991) Development of a flow boiling map for subcooled and saturated flow boiling of different fluids inside circular tubes. J Heat Transf 113(1):190–200

Kandlikar SG (1998) Heat transfer characteristics in partial boiling, fully developed boiling, and significant void flow regions of subcooled flow boiling. J Heat Transf 120(2):395–401

Kandlikar SG (1990) A general correlation for saturated two-phase flow boiling heat transfer inside horizontal and vertical tubes. J Heat Transf 112(1):219–228

Schrock VE, Grossman LM (1962) Forced convection boiling in tubes. Nucl Sci Eng 12(4):474–481

Shah MM (1977) A general correlation for heat transfer during subcooled boiling in pipes and annuli. ASHRAE Trans 83(1):202–217

Shah MM (1982) Chart correlation for saturated boiling heat transfer: equations and further study. ASHRAE Trans:88

Gungor KE, Winterton RHS (1986) A general correlation for flow boiling in tubes and annuli. Int J Heat Mass Transf 29(3):351–358

Lazarek GM, Black SH (1982) Evaporative heat transfer, pressure drop and critical heat flux in a small vertical tube with R-113. Int J Heat Mass Transf 25(7):945–960

Liu Z, Winterton RHS (1991) A general correlation for saturated and subcooled flow boiling in tubes and annuli, based on a nucleate pool boiling equation. Int J Heat Mass Transf 34(11):2759–2766

Ahangar Zonouzi S, Safarzadeh H, Aminfar H, Mohammadpourfard M (2018) Experimental and numerical study of swirling subcooled flow boiling of water in a vertical annulus. Experimental Heat Transfer 31(6):513–530

Zonouzi SA, Safarzadeh H, Aminfar H, Mohammadpourfard M (2018) Experimental study of subcooled boiling heat transfer of axial and swirling flows inside mini annular gaps. Journal of Applied Fluid Mechanics 11(1)

Zonouzi SA, Khodabandeh R, Safarzadeh H, Aminfar H, Mohammadpourfard M, Ghanbarpour M (2019) Experimental study of the subcooled flow boiling heat transfer of magnetic nanofluid in a vertical tube under magnetic field. J. Therm. Anal. Calorim.:1–12

Bertola V (ed) (2014) Modelling and experimentation in two-phase flow, vol 450. Springer

Merilo M (1977) Critical heat flux experiments in a vertical and horizontal tube with both Freon-12 and water as coolant. Nucl Eng Des 44(1):1–16

Merilo M (1979) Fluid-to-fluid modeling and correlation of flow boiling crisis in horizontal tubes. Int J Multiphase Flow 5(5):313–325

Wojtan L, Revellin R, Thome JR (2006) Investigation of saturated critical heat flux in a single, uniformly heated microchannel. Exp Thermal Fluid Sci 30(8):765–774

Zhang W, Hibiki T, Mishima K, Mi Y (2006) Correlation of critical heat flux for flow boiling of water in mini-channels. Int J Heat Mass Transf 49(5):1058–1072

Shah MM (2015) A general correlation for critical heat flux in horizontal channels. Int J Refrig 59:37–52

Wu Z, Li W, Ye S (2011) Correlations for saturated critical heat flux in microchannels. Int J Heat Mass Transf 54(1):379–389

Shah MM (1987) Improved general correlation for critical heat flux during upflow in uniformly heated vertical tubes. Int J Heat Fluid Flow 8(4):326–335

Hahne E, Spindler K, Skok H (1993) A new pressure drop correlation for subcooled flow boiling of refrigerants. Int J Heat Mass Transf 36(17):4267–4274

Baburajan PK, Bisht GS, Gupta SK, Prabhu SV (2013) Measurement of subcooled boiling pressure drop and local heat transfer coefficient in horizontal tube under LPLF conditions. Nucl Eng Des 255:169–179

Didi MO, Kattan N, Thome JR (2002) Prediction of two-phase pressure gradients of refrigerants in horizontal tubes. Int J Refrig 25(7):935–947

Müller-Steinhagen H, Heck K (1986) A simple friction pressure drop correlation for two-phase flow in pipes. Chem Eng Process Process Intensif 20(6):297–308

Grönnerud R (1972) Investigation of liquid hold-up, flow-resistance and heat transfer in circulation type evaporators, part IV: two-phase flow resistance in boiling refrigerants. Bull. De l’Inst. Du Froid, Annexe, 1

Lockhart RW, Martinelli RC (1949) Proposed correlation of data for isothermal two-phase, two-component flow in pipes. Chem Eng Prog 45(1):39–48

Yu W, France DM, Wambsganss MW, Hull JR (2002) Two-phase pressure drop, boiling heat transfer, and critical heat flux to water in a small-diameter horizontal tube. Int J Multiphase Flow 28(6):927–941

Chisholm D (1973) Pressure gradients due to friction during the flow of evaporating two-phase mixtures in smooth tubes and channels. Int J Heat Mass Transf 16(2):347–358

Xu Y, Fang X, Su X, Zhou Z, Chen W (2012) Evaluation of frictional pressure drop correlations for two-phase flow in pipes. Nucl Eng Des 253:86–97

Sun L, Mishima K (2009) Evaluation analysis of prediction methods for two-phase flow pressure drop in mini-channels. Int J Multiphase Flow 35(1):47–54

Xu Y, Fang X (2012) A new correlation of two-phase frictional pressure drop for evaporating flow in pipes. Int J Refrig 35(7):2039–2050

Hardik BK, Prabhu SV (2016) Boiling pressure drop and local heat transfer distribution of water in horizontal straight tubes at low pressure. Int J Therm Sci 110:65–82

Friedel L (1979) Improved friction pressure drop correlations for horizontal and vertical two-phase pipe flow. In European Two-Phase Flow Group Meeting, Ispra, Italy, 1979

Churchill SW, Chu HH (1975) Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int J Heat Mass Transf 18(9):1049–1053

NIST Reference Fluid Thermodynamic and Transport Properties Database (REFPROP version 7). https://webbook.nist.gov/chemistry/fluid/

Winterton RH (1998) Where did the Dittus and Boelter equation come from? Int J Heat Mass Transf 41(4–5):809–810

Gnielinski V (1976) New equations for heat and mass transfer in turbulent pipe and channel flow. International Chemical Engineering 16(2):359–368

Rouhani SZ, Axelsson E (1970) Calculation of void volume fraction in the subcooled and quality boiling regions. Int J Heat Mass Transf 13(2):383–393

Santini L, Cioncolini A, Lombardi C and Ricotti M (2014) Dryout occurrence in a helically coiled steam generator for nuclear power application. In EPJ Web of Conferences (Vol. 67, p. 02102). EDP sciences

Chen CN, Han JT, Jen TC, Shao L, Chen WW (2011) Experimental study on critical heat flux characteristics of R134a flow boiling in horizontal helically-coiled tubes. Int J Therm Sci 50(2):169–177

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Thermal Fluid Sci 1(1):3–17

Hardik BK, Kumar G, Prabhu SV (2017) Boiling pressure drop, local heat transfer distribution and critical heat flux in horizontal straight tubes. Int J Heat Mass Transf 113:466–481

Liu X, Chen X, Zhang Q, Wang S, Hou Y, Chen L (2017) Investigation on CHF of saturated liquid nitrogen flow boiling in a horizontal small channel. Appl Therm Eng 125:1025–1036

Ghiaasiaan SM (2007) Two-phase flow, boiling, and condensation: in conventional and miniature systems. Cambridge University Press

Prabhul K, Baburajan PK, Gupta SK, Prabhu SV (2010) Experimental investigation on critical heat flux in horizontal channel for low pressure low flow (LPLF) condition. Ann Nucl Energy 37(11):1467–1475

Roday AP, Jensen MK (2009) Study of the critical heat flux condition with water and R-123 during flow boiling in microtubes. Part I: experimental results and discussion of parametric effects. Int J Heat Mass Transf 52(13–14):3235–3249

Qu W, Mudawar I (2004) Measurement and correlation of critical heat flux in two-phase micro-channel heat sinks. Int J Heat Mass Transf 47(10):2045–2059

Acknowledgments

The authors would like to acknowledge the funding provided by the Ministry of Defence (R and D) India. Authors are grateful to Mr. Gajendra Kumar Verma and Mr. Rahul Shirsat for their support in the fabrication work of the test section and carrying out experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

1.1 Experimental heat loss calculation

Heat loss from the test section is by natural convection heat loss and radiative heat loss from the test section to the ambient air. Both these losses depend mainly upon the surface temperature of the test section. Heat loss experiments are performed with an empty test section, which is supplied with electric heating. The test section is heated with constant heating and allowed to cool by convection and radiation at ambient conditions. At steady-state conditions, heat supplied to the test section is equal to heat loss from the test section due to energy balance. At steady-state conditions, room temperature, heat supplied, and surface temperature of the test section are recorded. Experiments are performed at an average wall temperature from 34.8 °C to 68.6 °C. A curve is plotted between heat loss (Heat supplied) and ΔT (Wall temperature – Ambient air temperature). Thus from the Graph plotted, equation Qloss = 0.8063 × ΔT is obtained for the heat loss calculation. Theoretical heat loss is also verified by calculating radiation heat loss using radiation heat transfer coefficient and convection heat transfer coefficient using Churchill and Chu equation. The convective heat transfer coefficient using Churchill and Chu equation is in the range of 5.78 to 7.45. But, keeping the h = 8 W/m2 for convective heat loss, the total heat loss comes out to be the same as experimental heat loss with a maximum deviation of 3%.

In the present work, heat loss calculation is done as per the theoretical heat loss, as shown in Table 9. Combined convection and radiation heat loss is negligibly small compared to heat transferred to the fluid for the entire range of temperature in our experimental work. As the heat loss has a single-phase heat transfer coefficients, whereas boiling phenomena have a two-phase heat transfer coefficient, which is much significant. Further, we have R-123 as a working fluid that has less boiling point, so; wall temperature does not exceed much; hence radiation loss is also negligible. Despite the heat losses being small, these heat losses are considered in calculating the heat transfer coefficient.

Appendix 3

Summary of mass flux, current, and voltage data measured across the test section during the experimental work.

The measured voltage, current, and mass flux values at each steady stage condition are tabulated and given below for all the three test sections.

Heated Length = 400 mm | Heated Length = 600 mm | Heated Length = 1000 mm | ||||||

|---|---|---|---|---|---|---|---|---|

Mass Flux | Voltage | Current | Mass Flux | Voltage | Current | Mass Flux | Voltage | Current |

kg/m2s | Volt | Amp | kg/m2s | Volt | Amp | kg/m2s | Volt | Amp |

181.4 | 0 | 0 | 182.2 | 0 | 0 | 178.3 | 0 | 0 |

182.7 | 2.55 | 130 | 176.5 | 3.79 | 130 | 192.6 | 4.9 | 102 |

184.1 | 2.73 | 139 | 185.1 | 4.4 | 151 | 193.5 | 5.88 | 122 |

181.3 | 2.99 | 152 | 179.9 | 5.34 | 181 | 190.6 | 7.43 | 152 |

181.4 | 3.29 | 166 | 175.9 | 5.97 | 201 | 186.1 | 8.97 | 182 |

180.6 | 3.82 | 191 | 358.8 | 0 | 0 | 181.9 | 9.79 | 196 |

179.9 | 4.05 | 201 | 359.9 | 5.1 | 140 | 358.6 | 0 | 0 |

354.4 | 0 | 0 | 358.2 | 5.46 | 180 | 354.0 | 6.5 | 130 |

353.7 | 3.48 | 170 | 359.3 | 5.14 | 190 | 349.3 | 8.07 | 160 |

350.8 | 3.9 | 189 | 361.9 | 6.08 | 200 | 345.7 | 8.7 | 172 |

349.5 | 4.04 | 195 | 498.1 | 0 | 0 | 344.6 | 10.23 | 200 |

494.5 | 0 | 0 | 496.2 | 3.8 | 131 | 490.2 | 0 | 0 |

491.9 | 3.54 | 178 | 492.9 | 4.66 | 160 | 490.2 | 6.35 | 130 |

495.6 | 4 | 200 | 490.8 | 5.32 | 181 | 492.9 | 7.88 | 161 |

494.7 | 4.33 | 217 | 497.2 | 6.17 | 210 | 492.9 | 9.37 | 191 |

492.6 | 4.62 | 230 | 497.0 | 6.65 | 224 | 488.5 | 10.4 | 211 |

491.1 | 4.76 | 233 | 627.9 | 0 | 0 | 491.4 | 11 | 220 |

625.1 | 3.89 | 190 | 635.2 | 4.32 | 140 | 645.0 | 0 | 0 |

624.9 | 4.71 | 230 | 634.2 | 5.46 | 180 | 645.1 | 7.07 | 140 |

624.5 | 4.92 | 240 | 632.5 | 6.95 | 227 | 646.1 | 9.12 | 180 |

901.8 | 0 | 0 | 903.7 | 4.21 | 140 | 652.4 | 11.16 | 220 |

900.5 | 2.66 | 130 | 905.9 | 5.42 | 180 | 658.3 | 12.19 | 240 |

903.2 | 3.07 | 150 | 910.3 | 6.97 | 230 | 900.9 | 0 | 0 |

907.2 | 3.48 | 170 | 910.5 | 7.76 | 256 | 901.6 | 5.01 | 100 |

908.0 | 3.9 | 190 | 1169.2 | 0 | 0 | 905.3 | 7.03 | 140 |

907.1 | 4.29 | 210 | 1172.3 | 4.2 | 140 | 911.9 | 9.05 | 180 |

909.0 | 4.72 | 230 | 1174.7 | 5.45 | 180 | 925.6 | 11.66 | 230 |

912.0 | 5.13 | 250 | 1181.0 | 6.97 | 230 | 935.0 | 12.66 | 250 |

914.4 | 5.55 | 270 | 1188.0 | 7.9 | 260 | 945.4 | 13.76 | 270 |

902.7 | 5.96 | 290 | 1197.2 | 8.85 | 290 | 951.3 | 14.52 | 285 |

906.6 | 6.39 | 310 | 1206.7 | 9.45 | 310 | 1171.8 | 0 | 0 |

911.0 | 6.83 | 330 | 1207.3 | 10.1 | 330 | 1178.8 | 4.86 | 100 |

916.4 | 7.42 | 360 | 1201.4 | 10.71 | 360 | 1183.9 | 7.05 | 140 |

920.6 | 7.87 | 382 | 1196.2 | 11.19 | 376 | 1192.8 | 9.06 | 180 |

1183.0 | 0 | 0 | 1211.2 | 11.67 | 230 | |||

1169.3 | 3.5 | 170 | 1221.7 | 12.71 | 250 | |||

1172.6 | 4.74 | 230 | 1237.0 | 14.3 | 280 | |||

1179.6 | 5.57 | 270 | 1216.8 | 15.34 | 300 | |||

1190.2 | 6.4 | 310 | 1231.1 | 16.38 | 320 | |||

1180.1 | 7.46 | 360 | 1211.0 | 17 | 333 | |||

1190.6 | 8.12 | 390 | ||||||

1162.0 | 8.7 | 418 | ||||||

Rights and permissions

About this article

Cite this article

Tank, P.N., Hardik, B.K., Sridharan, A. et al. Pressure drop, local heat transfer coefficient, and critical heat flux of DNB type for flow boiling in a horizontal straight tube with R-123. Heat Mass Transfer 57, 223–250 (2021). https://doi.org/10.1007/s00231-020-02935-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02935-5