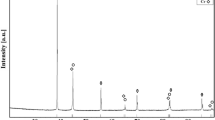

Recent research on nanocrystalline FeAl alloys has shown that these alloys are of high importance due to their promising structural and mechanical properties, particularly magnetic behavior. This work aims at studying the synthesis, structural and magnetic characterization of nanocrystalline FeAl alloy powders, prepared by a mechanical alloying process (MA), as well as the effect of Ti addition on the magnetic properties of a compound. The powder morphology, phase transformation, crystallite size, micro-stress evolution, and magnetic properties were investigated by X-ray diffraction (XRD), scanning electronic microscopy (SEM), and vibrating samples magnetometer (VSM). It has been found that at the final stage of mechanical alloying the bcc-disordered FeAl phase and nanocrystalline Fe(Al, Ti) solid solution occurred for the FeAl40 and FeAl40Ti3 alloys, respectively. The milling time and the addition of titanium affect the powder morphology and decrease the size of the particles. The average crystallites size of 17.2 and 11.2 nm was reached at the end of 30 h of milling, and the lattice strain increased up to 0.3 and 0.21% for the FeAl40 and FeAl40Ti3 alloys, respectively. Also, the magnetic properties attributed to microstructural changes were investigated. It has been established that the change in magnetic behavior occurs mainly due to the formation of a supersaturated Fe(Al, Ti) solid solution. Magnetic properties of the samples are highly influenced by the addition of the Ti element into FeAl40 alloy, as well. The magnetism of the FeAl40Ti3 compound is reported to be higher than that of FeAl40.

Similar content being viewed by others

References

M. Krifa, M. Mhadhbi, L. Escoda, J. Saurina, J.J. Sunol, N. Llorca-Isern, C. Artieda-Guzmán, and M. Khitouni “Phase transformations during mechanical alloying of Fe–30% Al–20% Cu,” Powder Techn., 246, 117–124 (2013).

H. Ahmadian Baghbaderani, S. Sharafi, and M. Delshad Chermahini, “Investigation of nanostructure formation mechanism and magnetic properties in Fe45Co45Ni10 system synthesized by mechanical alloying,” Powder Techn., 230, 241–246 (2012).

A.R. Othman, A. Sardarinejad, and A.K. Masrom, “Effect of milling parameters on mechanical alloying of aluminum powders,” Int. J. Adv. Manuf. Technol., 76, 1319–1332 (2015).

S.M. Zhu, M. Tamura, K. Sakamoto, and K. Iwasaki, “Characterization of Fe3Al-based intermetallic alloys fabricated by mechanical alloying and HIP consolidation,” Mater. Sci. Eng. A., 292, 83–89 (2000).

J. Chao, D.-G. Morris, M.-A. Munoz-Morris, and J.-L. Gonzalez Carrasco, “The influence of some microstructural and test parameters on the tensile behaviour and the ductility of a mechanically-alloyed Fe– 40Al alloy,” Intermetallics, 9, 299–308 (2001).

K.-H. Sim, G. Wang, R.-C. Son, and S.-L. Choe, “Influence of mechanical alloying on the microstructure and mechanical properties of powder metallurgy Ti2AlNb-based alloy,” Powder Techn., 317, 133–141 (2017).

P.A. Loginov, E.A. Levashov, V.V. Kurbatkina, A.A. Zaitsev, and D.A. Sidorenko “Evolution of the microstructure of Cu–Fe–Co–Ni powder mixtures upon mechanical alloying,” Powder Techn., 276, 166–174 (2015).

K. Kato and T. Masui, “Influence of boron addition on the tensile properties of sintered FeAl compacts by powder injection molding,” J. Jpn. Soc. Powder Powder Metall., 49, No. 9, 787–792 (2002).

M. Krasnowski and T. Kulik , “Nanocrystalline FeAl intermetallic produced by mechanical alloying followed by hot-pressing consolidation,” Intermetallics, 15, 201–205 (2007).

P. Haušild, J. Siegl, P. Málek, and V. Šíma, “Effect of C, Ti, Zr, and B alloying on fracture mechanisms in hot-rolled Fe–40 (at.%) Al,” Intermetallics, 17, 680–687 (2009).

S. Izadia, G.H. Akbaria, and K. Janghorbanb “Sintering and mechanical properties of mechanically alloyed Fe–Al–(B) nanostructures,” J. Alloys Compd., 496, 699–702 (2010).

D.D. Risanti and G. Sauthoff, “Microstructures and mechanical properties of Fe–Al–Ta alloys with strengthening Laves phase,” Intermetallics, 19, 1727–1736 (2011).

C. Suryanarayana, “Mechanical alloying and milling,” Prog. Mater. Sci., 46, 181–184 (2001).

G.M. Mendiratta, S.K. Ehlers, D.M. Dimiduk, W.R. Kerr, S. Mazdiyasni, and H.A. Lipsitt, Mat. Res. Soc. Symp. Proc., 81, 393–404 (1987).

M. Salazar, A. ALbiter, G. Rosas, and R. Perez, “Structural and mechanical properties of the AlFe intermetallic alloy with Li, Ce, and Ni additions,” Mater. Sci. Eng.: A., 351, 154–159 (2003).

L. Falat, A. Schneider, G. Sauthoff, and G. Frommeyer, “Mechanical properties of Fe–Al–M–C (M = Ti, V, Nb, Ta) alloys with strengthening carbides and Laves phase,” Intermetallics, 13, 1256–1262 (2005).

X. Lia, P. Prokopcáková, and M. Palma, “Microstructure and mechanical properties of Fe–Al–Ti–B alloys with additions of Mo and W,” Mater. Sci. Eng.: A, 611, 234–241 (2014).

Nguyen Thi Hoang Oanh, Nguyen Hoang Viet, Dina V. Dudina, Alberto Moreira Jorge Jr, and Ji-Soon Kim, “Structural characterization and magnetic properties of Al82Fe16TM2 (TM: Ti, Ni, Cu) alloys prepared by mechanical alloying,” J. Non-Crystal. Sol., 468, 67–73 (2017).

A. Younes, N. Dilmi, M. Khorchef, A. Bouamer, N-E. Bacha, and M. Zergoug, “Structural and magnetic properties of FeCuNi nanostructured produced by mechanical alloying,” Appl. Surf. Sci. 446, 258–265 (2018).

N.E. Fenineche, R. Hamzaoui, and O. El Kedim, “Structure and magnetic properties of nanocrystalline Co–Ni and Co–Fe mechanically alloyed,” Mater. Lett., 57, 4165–4169 (2003).

C. Senderowski, D. Zasada, T. Durejko, and Z. Bojar, “Characterization of as-synthesized and mechanically milled Fe–Al powders produced by the self-disintegration method,” Powder Techn., 263, 96– 103 (2014).

A.R. Stokes and A.C.J.Wilson, “The diffraction of X-rays by distorted crystal aggregates,” Proc. Phys. Soc. Lond., 56, 174–181 (1944).

A. Younes, N-E. Bacha, M. Zergoug, and N. Dilmi, “Structural and magnetic properties of Fe–Co/Al2O3 nanocomposite powder produced by mechanical alloying,” Powder Metall. Met. Ceram., 56, No. 3–4, 148– 157 (2017).

S.M. Zhu and K. Iwasaki , “Characterization of mechanically alloyed ternary Fe–Ti–Al powders,” Mater. Sci. Eng.: A, 270, 170 (1999).

W. Maziarz, J. Dutkiewicz, J. Van Humbeeck, and T. Czeppe, “Processing of nanocrystalline FeAlX (X = Ni, Mn) intermetallics using a mechanical alloying and hot pressing techniques,” J. Mater. Sci., 39, 5425 (2004).

H.J. Fecht, G. Han, Z. Fu, and W.L. Johnson “Metastable phase formation in the Zr–Al binary system induced by mechanical alloying,” J. Appl. Phys., 67, No. 15, 1744–1748 (1990).

Run-hua Fan, Jia-tao Sun, Hong-yu Gong, Kang-ning Sun, and Wei-min Wang, “Structural evolution of mechanically alloyed nanocrystalline Fe–28Al powders,” Powder Techn., 149, 121–126 (2005).

M. Mhadhbi, M. Khitouni, M. Azabou, and A. Kolsi, “Characterization of Al and Fe nanosized powders synthesized by high energy mechanical milling,” Mater. Charact., 59, 944–950 (2008).

M.M. Rajath Hegde and A.O. Surendranathan, “Phase transformation, structural evolution and mechanical property of nanostructured FeAl as a result of mechanical alloying,” Russian J. Non-Ferrous Metals, 50, 474–484 (2009).

R. Bernal-Correa, A. Rosales-Rivera, P. Pineda-Gómez, and N.A. Salazar, “Structural and magnetic properties of Fe60Al40 alloys prepared by means of a magnetic mill,” J. Alloys Compd., 495, 491 (2010).

Y. Jiraskova, J. Bursik, O. Zivotsky, and J. Cuda “Influence of Fe2O3 on alloying and magnetic properties of Fe–Al. Mater. Sci. Eng. B,” 186, 73–78 (2014).

M.H. Enayati and M. Salehi, “Formation mechanism of Fe3Al and FeAl intermetallic compounds during mechanical alloying,” J. Mater. Sci.,” 40, 3933–3938 (2005).

S. Haixia, W. Yunxin, T. Chuan’an, Y. Shuai, and G. Qianming, “Microstructure and mechanical properties of FeAl intermetallics prepared by mechanical alloying and hot-pressing,” Tsinghua Sci. Techn., 14, 300–306 (2009).

Z. Hamlati, A. Guittoum, S. Bergheul, N. Souami, K. Taibi, and M. Azzaz, “X-Ray diffraction, microstructure, and mo¨ssbauer studies of Fe72Al28 alloy elaborated by mechanical milling,” J. Mater. Eng. Perform., 21, 1943–1948 (2012).

I. Chicinas, V. Pop, and O. Isnard, “Synthesis of the super alloy powders by mechanical alloying,” J. Mater. Sci., 39, 5305–5309 (2004).

R. Bernal-Correa, A. Rosales-Rivera, P. Pineda-Gómez, and N.A. Salazar, “Structural and magnetic properties of Fe60Al40 alloys prepared by means of a magnetic mill,” J. Alloys Compd., 495, 491–494 (2010).

X. Amils, J. Nogués, S. Suriñach, M.D. Barò, M.A. Muñoz-Morris, and D.G. Morris, “Hardening and softening of FeAl during milling and annealing,” Intermetallics, 8, No. 7, 805–813 (2000).

R. Fan, J. Sun, H. Gong, K. Sun, and W. Wang “Structural evolution of mechanically alloyed nanocrystalline Fe–28Al powders,” Powder Techn., 149, 121–126 (2005).

L.E. Zamora, G.A. Pérez Alcázar, G.Y. Vélez, J.D. Betancur, J.F. Marco, J.J. Romero, A. Martínez, F.J. Palomares, and J.M. González, “Disorder effect on the magnetic behavior of mechanically alloyed Fe1–xAlx (0.2 ≤ x ≤ 0.4),” Phys. Rev. B., 79, 094418 (2009).

C. Suryanarayana, E. Ivanov, and V.V. Boldyrev, “The science and technology of mechanical alloying. Mater. Sci. Eng. A,” 304–306, 151–158 (2001).

A. Younes, M. Khorchef, A. Bouamer, and H. Amar, “Magnetic and structural Behavior of Fe–CoO nanocomposites mechanically milled,” Mater. Sci. Eng., 557, 1–12 (2019).

S. Enzo, R. Frattini, R. Gupta, P.P. Macri, G. Principi, L. Schiffini, and G. Scipione, “X-ray powder diffraction and Mössbauer study of nanocrystalline Fe–Al prepared by mechanical alloying,” Acta Mater., 44, 3105–3113 (1996).

J.A. Plascak, E. Zamora Ligia, and G.A. Pérez Alcazar, “Ising model for disordered ferromagnetic Fe−Al alloys,” Phys. Rev. B,” 61, 3188 (2000).

K.H.J. Buschow and F.R. de Boer, Physics of Magnetism and Magnetic Materials, Springer, Boston, MA, (2003).

E.C. Stoner and E.P. Wohlfarth, “A mechanism of magnetic hysteresis in heterogeneous alloys,” IEEE Trans. Magnet., 27, 3475–3518 (1991).

G. Herzer, “Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets,” IEEE Trans. Magnet., 26, 1397–1402 (1990).

Acknowledgments

The authors would like to thank Dr.A. Guittoum (Nuclear Research Centre, Algiers, Algeria) for assistance in X-ray patterns analysis by the High Score Plus software.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 59, Nos. 3–4 (532), pp. 55–68, 2020.

Rights and permissions

About this article

Cite this article

Metidji, N., Bacha, N.E., Younes, A. et al. The Effect of Ti Addition on Microstructure and Magnetic Properties of Nanocrystalline FeAl40 Alloy Powders Prepared by Mechanical Alloying. Powder Metall Met Ceram 59, 160–170 (2020). https://doi.org/10.1007/s11106-020-00148-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00148-3