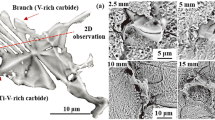

The crystal structure acquired by powder steels produced from undoped iron powder and mixtures of iron with 1.0 or 1.5% graphite in hot forging was studied by X-ray diffraction and optical microscopy. The heating temperature of the samples to be forged was varied in the range 950–1150°C. The fundamentally different dependence of the lattice distortion on the heating temperature for forging of the outer and inner layers of the samples was found. The lattice imperfection increases with forging temperature in the outer layers of the hot-forged samples made of the undoped iron powder. The γ→α martensitic transformation occurs when the samples are heated above 1100°C and rapidly cooled down. The lattice imperfection decreases in the inner layers of the samples made of the undoped iron powder. In the case of carbon steel samples, the lattice distortion and hardness increase with heating temperature, reaching the maximum at 1100°C and thus characterizing the γ→α martensitic transformation. When temperature increases to 1150°C, the lattice imperfection reduces as carbon burns out more intensively at elevated temperatures, but the hardness and tensile strength decrease insignificantly. This is attributed to the quenching temperature of steel to form a ferritic cement mixture, whose structure is presented by sorbitol with a microhardness of 2700– 2900 MPa, troostite (3000 MPa), and bainite (4500 MPa).

Similar content being viewed by others

References

Yu.G. Dorofeev, B.G. Gasanov, V.Yu. Dorofeev, V.N. Mishchenko, and V.I. Miroshnikov, Industrial Hot Pressing of Powder Parts [in Russian], Metallurgiya, Moscow (1990), p. 206.

V.M. Gorokhov, E.A. Doroshkevich, and G.M. Efimov, Bulk Forging of Powder Materials [in Russian], Nauka i Tekhnika, Minsk (1993), p. 272.

H.A. Kuhn and B.L. Ferguson, “Powder forging,” Part. Mater., 2, 173–214 (1994).

A.A. Hendrickson, P.M. Machmeier, and D.W. Smith, “Impact forging of sintered steel preforms,” Powder Metall., 43, No. 4, 327–344 (2000).

G.A. Baglyuk, “Effect of strain parameters on the structure and properties of hot-forged powder materials,” Obrab. Met. Davl., No. 1, 139–145 (2011).

Yu.G. Dorofeev and V.Yu. Dorofeev, “Hot pressing and deformation of powder ingots,” in: Fifty Years of Belarus Powder Metallurgy. History, Advances, and Prospects [in Russian], Minsk (2010), pp. 75–111.

Yu.G. Dorofeev, “Evolution of the theory and technology of hot pressing of particulate materials,” in: Powder and Composite Materials and Parts (Collected Scientific Papers) [in Russian], Yuzh. Ros. Gos. Tekh. Univ., Novocherkassk (2000), pp. 4–12.

H.K. Cho, J. Suh, and K.T. Kim, “Densification of porous alloy steel preforms at high temperature,” Int. J. Mech. Sci., 36, No. 4, 317–328 (1994).

V.Yu. Dorofeev and S.N. Egorov, Interparticle Coalescence to Form Hot-Forged Powder Materials [in Russian], Metallurgizdat, Moscow (2003), p. 151.

G.A. Bagliuk and A.A. Mamonova, “Martensitic structures in hot-forged powder carbon steels,” in: Proc. 9th Int. Conf. Materials and Coatings in Extreme Conditions [in Russian], Kyiv (2016), pp. 88–90.

G.A. Baglyuk, “Improvement of powder material deformation based on controlling contact friction forces,” Powder Metall. Met. Ceram., 41, No. 1–2, 17–22 (2002).

A.A. Mamonova, “Effect of martensitic transformation on the substructure of hot-forged powder steels,” in: Proc. 7th Int. Conf. Phase Transformations and Strength of Crystals. To the 110th Birth Anniversary of Academician Kurdyumov [in Russian], Chernogolovka (2012), p. 136.

M.A. Krivoglaz, Theory of X-Ray and Thermal Neutron Scattering by Real Crystals [in Russian], Nauka, Moscow (1967), p. 336.

M.A. Krivoglaz, X-Ray and Neutron Diffraction in Imperfect Crystals [in Russian], Naukova Dumka, Kyiv (1983), p. 408.

Ya.S. Umanskii, Yu.A. Skakov, A.N. Ivanov, and L.N. Rastorguev, Crystallography, X-Ray Diffraction, and Electron Microscopy [in Russian], Metallurgiya, Moscow (1982), p. 632.

S.S. Gorelik, Yu.A. Skakov, and L.N. Rastorguev, X-Ray Diffraction and Electron Optic Analysis [in Russian], MISIS, Moscow (2002), p. 360.

Outstanding Scientists of Ukraine. G. V. Kurdyumov. Selected Papers [in Ukrainian], Akademperiodika, Kyiv (2002), p. 776.

G.V. Kurdyumov, L.M. Utevskii, and R.I. Entin, Transformations in Iron and Steel [in Russian], Nauka, Moscow (1977), p. 238.

V.N. Antsiferov and V.G. Gilev, “Study of the martensite structure in sintered carbon steels,” Izv. Vus. Chern. Metall., No. 5, 99–102 (1982).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 3–4 (532), pp. 149–159, 2020.

Rights and permissions

About this article

Cite this article

Mamonova, A., Bagliuk, G. Formation of Crystal Structure in Hot Forging of Powder Carbon Steels. Powder Metall Met Ceram 59, 232–238 (2020). https://doi.org/10.1007/s11106-020-00155-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00155-4