Abstract

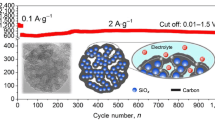

Porous Si can be synthesized from diverse silica (SiO2) via magnesiothermic reduction technology and widely employed as potential anode material in lithium ion batteries. However, concerns regarding the influence of residual silicon oxide (SiOx) component on resulted Si anode after reduction are still lacked. In this work, we intentionally fabricate a cauliflower-like silicon/silicon oxide (CF-Si/SiOx) particles from highly porous SiO2 spheres through insufficient magnesiothermic reduction, where residual SiOx component and internal space play an important role in preventing the structural deformation of secondary bulk and restraining the expansion of Si phase. Moreover, the hierarchically structured CF-Si/SiOx exhibits uniformly-dispersed channels, which can improve ion transport and accommodate large volume expansion, simultaneously. As a result, the CF-Si/SiOx-700 anode shows excellent electrochemical performance with a specific capacity of ~1,400 mA·h·g−1 and a capacity retention of 98% after 100 cycles at the current of 0.2 A·g−1.

Similar content being viewed by others

References

Armand, M.; Tarascon, J. M. Building better batteries. Nature 2008, 451, 652–657.

Tarascon, J. M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367.

An, W. L.; Gao, B.; Mei, S. X.; Xiang, B.; Fu, J. J.; Wang, L.; Zhang, Q. B.; Chu, P. K.; Huo, K. F. Scalable synthesis of ant-nest-like bulk porous silicon for high-performance lithium-ion battery anodes. Nat. Commun. 2019, 10, 1447.

McDowell, M. T.; Lee, S. W.; Harris, J. T.; Korgel, B. A.; Wang, C. M.; Nix, W. D.; Cui, Y. In situ tem of two-phase lithiation of amorphous silicon nanospheres. Nano Lett. 2013, 13, 758–764.

Liu, X. H.; Zhong, L.; Huang, S.; Mao, S. X.; Zhu, T.; Huang, J. Y. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 2012, 6, 1522–1531.

Kim, H.; Seo, M.; Park, M. H.; Cho, J. A critical size of silicon nano-anodes for lithium rechargeable batteries. Angew. Chem., Int. Ed. 2010, 49, 2146–2149.

Ren, Y. P.; Zhou, X. Y.; Tang, J. J.; Ding, J.; Chen, S.; Zhang, J. M.; Hu, T. J.; Yang, X. S.; Wang, X. M.; Yang, J. Boron-doped spherical hollow-porous silicon local lattice expansion toward a highperformance lithium-ion-battery anode. Inorg. Chem. 2019, 58, 4592–4599.

Shivaraju, G. C.; Sudakar, C.; Prakash, A. S. High-rate and long-cycle life performance of nano-porous nano-silicon derived from mesoporous MCM-41 as an anode for lithium-ion battery. Electrochim. Acta 2019, 294, 357–364.

Liang, G. M.; Qin, X. Y.; Zou, J. S.; Luo, L. Y.; Wang, Y. Z.; Wu, M. Y.; Zhu, H.; Chen, G. H.; Kang, F. Y.; Li, B. H. Electrosprayed silicon-embedded porous carbon microspheres as lithium-ion battery anodes with exceptional rate capacities. Carbon 2018, 127, 424–431.

Wu, J. X.; Qin, X. Y.; Miao, C.; He, Y. B.; Liang, G. M.; Zhou, D.; Liu, M.; Han, C. P.; Li, B. H.; Kang, F. Y. A honeycomb-cobweb inspired hierarchical core-shell structure design for electrospun silicon/carbon fibers as lithium-ion battery anodes. Carbon 2016, 98, 582–591.

Yun, Q. B.; Qin, X. Y.; Lv, W.; He, Y. B.; Li, B. H.; Kang, F. Y.; Yang, Q. H. “Concrete” inspired construction of a silicon/carbon hybrid electrode for high performance lithium ion battery. Carbon 2015, 93, 59–67.

Wu, J. X.; Qin, X. Y.; Zhang, H. R.; He, Y. B.; Li, B. H.; Ke, L.; Lv, W.; Du, H. D.; Yang, Q. H.; Kang, F. Y. Multilayered silicon embedded porous carbon/graphene hybrid film as a high performance anode. Carbon 2015, 84, 434–443.

Zhang, H. R.; Qin, X. Y.; Wu, J. X.; He, Y. B.; Du, H. D.; Li, B. H.; Kang, F. Y. Electrospun core-shell silicon/carbon fibers with an internal honeycomb-like conductive carbon framework as an anode for lithium ion batteries. J. Mater. Chem. A 2015, 3, 7112–7120.

Zhang, R. Y.; Du, Y. J.; Li, D.; Shen, D. K.; Yang, J. P.; Guo, Z. P.; Liu, H. K.; Elzatahry, A. A.; Zhao, D. Y. Highly reversible and large lithium storage in mesoporous Si/C nanocomposite anodes with silicon nanoparticles embedded in a carbon framework. Adv. Mater. 2014, 26, 6749–6755.

Entwistle, J.; Rennie, A.; Patwardhan, S. A review of magnesiothermic reduction of silica to porous silicon for lithium-ion battery applications and beyond. J. Mater. Chem. A 2018, 6, 18344–18356.

Kim, B.; Ahn, J.; Oh, Y.; Tan, J. W.; Lee, D.; Lee, J. K.; Moon, J. Highly porous carbon-coated silicon nanoparticles with canyon-like surfaces as a high-performance anode material for Li-ion batteries. J. Mater. Chem. A 2018, 6, 3028–3037.

Xu, Z. L.; Gang, Y.; Garakani, M. A.; Abouali, S.; Huang, J. Q.; Kim, J. K. Carbon-coated mesoporous silicon microsphere anodes with greatly reduced volume expansion. J. Mater. Chem. A 2016, 4, 6098–6106.

Chun, J.; An, S.; Lee, J. Highly mesoporous silicon derived from waste iron slag for high performance lithium ion battery anodes. J. Mater. Chem. A 2015, 3, 21899–21906.

Jia, H. P.; Zheng, J. M.; Song, J. H.; Luo, L. L.; Yi, R.; Estevez, L.; Zhao, W. G.; Patel, R.; Li, X. L.; Zhang, J. G. A novel approach to synthesize micrometer-sized porous silicon as a high performance anode for lithium-ion batteries. Nano Energy 2018, 50, 589–597.

Li, Y. Z.; Yan, K.; Lee, H. W.; Lu, Z. D.; Liu, N.; Cui, Y. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat. Energy 2016, 1, 15029.

Jia, H. P.; Zheng, J. M.; Song, J. H.; Luo, L. L.; Yi, R.; Estevez, L.; Zhao, W. G.; Patel, R.; Li, X. L.; Zhang, J. G. A novel approach to synthesize micrometer-sized porous silicon as a high performance anode for lithium-ion batteries. Nano Energy 2018, 50, 589–597.

Xu, Q.; Li, J. Y.; Sun, J. K.; Yin, Y. X.; Wan, L. J.; Guo, Y. G. Watermelon-inspired Si/C microspheres with hierarchical buffer structures for densely compacted lithium-ion battery anodes. Adv. Energy Mater. 2017, 7, 1601481

Bang, B. M.; Lee, J. I.; Kim, H.; Cho, J.; Park, S. High-performance macroporous bulk silicon anodes synthesized by template-free chemical etching. Adv. Energy Mater. 2012, 2, 878–883.

Wada, T.; Ichitsubo, T.; Yubuta, K.; Segawa, H.; Yoshida, H.; Kato, H. Bulk-nanoporous-silicon negative electrode with extremely high cyclability for lithium-ion batteries prepared using a top-down process. Nano Lett. 2014, 14, 4505–4510.

Li, X. L.; Gu, M.; Hu, S. Y.; Kennard, R.; Yan, P. F.; Chen, X. L.; Wang, C. M.; Sailor, M. J.; Zhang, J. G.; Liu, J. Mesoporous silicon sponge as an anti-pulverization structure for high-performance lithium-ion battery anodes. Nat. Commun. 2014, 5, 4105.

Ngo, D. T.; Le, H. T. T.; Pham, X. M.; Jung, J. W.; Vu, N. H.; Fisher, J. G.; Im, W. B.; Kim, I. D.; Park, C. J. Highly porous coral-like silicon particles synthesized by an ultra-simple thermal-reduction method. J. Mater. Chem. A 2018, 6, 2834–2846.

An, Y. L.; Fei, H. F.; Zeng, G. F.; Ci, L. J.; Xiong, S. L.; Feng, J. K.; Qian, Y. T. Green, scalable, and controllable fabrication of nanoporous silicon from commercial alloy precursors for high-energy lithium-ion batteries. ACS Nano 2018, 12, 4993–5002.

Xiao, Q. F.; Gu, M.; Yang, H.; Li, B.; Zhang, C. M.; Liu, Y.; Liu, F.; Dai, F.; Yang, L.; Liu, Z. Y. et al. Inward lithium-ion breathing of hierarchically porous silicon anodes. Nat. Commun. 2015, 6, 8844.

Zuo, X. X.; Xia, Y. G.; Ji, Q.; Gao, X.; Yin, S. S.; Wang, M. M.; Wang, X. Y.; Qiu, B.; Wei, A. X.; Sun, Z. C. et al. Self-templating construction of 3D hierarchical macro-/mesoporous silicon from 0D silica nanoparticles. ACS Nano 2017, 11, 889–899.

Son, Y.; Ma, J. Y.; Kim, N.; Lee, T.; Lee, Y.; Sung, J.; Choi, S. H.; Nam, G.; Cho, H.; Yoo, Y. et al. Quantification of pseudocapacitive contribution in nanocage-shaped silicon-carbon composite anode. Adv. Energy Mater. 2019, 9, 1803480.

Wang, J. Y.; Liao, L.; Lee, H. R.; Shi, F. F.; Huang, W.; Zhao, J.; Pei, A.; Tang, J.; Zheng, X. L.; Chen, W. et al. Surface-engineered mesoporous silicon microparticles as high-Coulombic-efficiency anodes for lithium-ion batteries. Nano Energy 2019, 61, 404–410.

Wang, J. Y.; Liao, L.; Li, Y. Z.; Zhao, J.; Shi, F. F.; Yan, K.; Pei, A.; Chen, G. X.; Li, G. D.; Lu, Z. Y. et al. Shell-protective secondary silicon nanostructures as pressure-resistant high-volumetric-capacity anodes for lithium-ion batteries. Nano Lett. 2018, 18, 7060–7065.

Yang, J. P.; Wang, Y. X.; Li, W.; Wang, L. J.; Fan, Y. C.; Jiang, W.; Luo, W.; Wang, Y.; Kong, B.; Selomulya, C. et al. Amorphous TiO2 shells: A vital elastic buffering layer on silicon nanoparticles for highperformance and safe lithium storage. Adv. Mater. 2017, 29, 1700523.

Lee, S. J.; Kim, H. J.; Hwang, T. H.; Choi, S.; Park, S. H.; Deniz, E.; Jung, D. S.; Choi, J. W. Delicate structural control of Si-SiOx-C composite via high-speed spray pyrolysis for Li-ion battery anodes. Nano Lett. 2017, 17, 1870–1876.

Hu, Y. S.; Demir-Cakan, R.; Titirici, M. M.; Müeller, J. O.; Schlöegl, R.; Antonietti, M.; Maier, J. Superior storage performance of a Si@SiOx/C nanocomposite as anode material for lithium-ion batteries. Angew. Chem., Int. Ed. 2008, 47, 1645–1649.

Benítez, A.; Di Lecce, D.; Elia, G. A.; Caballero, Á.; Morales, J.; Hassoun, J. A lithium-ion battery using a 3 D-array nanostructured graphene-sulfur cathode and a silicon oxide-based anode. ChemSusChem 2018, 11, 1512–1520.

Elia, G. A.; Hassoun, J. A SiOx-based anode in a high-voltage lithium-ion battery. ChemElectroChem 2017, 4, 2164–2168.

Arrebola, J. C.; Caballero, A.; Gómez-Cámer, J. L.; Hernán, L.; Morales, J.; Sánchez, L. Combining 5 V LiNi0.5Mn1.5O4 spinel and Si nanoparticles for advanced Li-ion batteries. Electrochem. Commun. 2009, 11, 1061–1064.

Yin, J. T.; Wada, M.; Yamamoto, K.; Kitano, Y.; Tanase, S.; Sakai, T. Micrometer-scale amorphous Si thin-film electrodes fabricated by electron-beam deposition for Li-ion batteries. J. Electrochem. Soc. 2006, 153, A472–A477.

Lee, K. L.; Jung, J. Y.; Lee, S. W.; Moon, H. S.; Park, J. W. Electrochemical characteristics and cycle performance of LiMn2O4/a-Si microbattery. J. Power Sources 2004, 130, 241–246.

Wang, J. Y.; Huang, W.; Kim, Y. S.; Jeong, Y. K.; Kim, S. C.; Heo, J.; Lee, H. K.; Liu, B. F.; Nah, J.; Cui, Y. Scalable synthesis of nanoporous silicon microparticles for highly cyclable lithium-ion batteries. Nano Res. 2020, 4, 1558–1563.

Wu, W.; Wang, M.; Wang, R.; Xu, D. W.; Zeng, H. B.; Wang, C. Y.; Cao, Y. L.; Deng, Y. H. Magnesio-mechanochemical reduced SiOx for high-performance lithium ion batteries. J. Power Sources 2018, 407, 112–122.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 51872157), Shenzhen Technical Plan Project (Nos. JCYJ20170817161753629 and JCYJ20180508152135822), the Shenzhen Graphene Manufacturing Innovation Center (No. 201901161513), Shenzhen Key Lab of Security Research of Power Batteries (No. ZDSYS201707271615073), Guangdong Technical Plan Project (Nos. 2015TX01N011 and 2017B090907005), Local Innovative and Research Teams Project of Guangdong Pearl River Talents Program (No. 2017BT01N111), and the Special Fund Project for Strategic Emerging Industry Development of Shenzhen (No. 20170428145209110).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Zeng, K., Li, T., Qin, X. et al. A combination of hierarchical pore and buffering layer construction for ultrastable nanocluster Si/SiOx anode. Nano Res. 13, 2987–2993 (2020). https://doi.org/10.1007/s12274-020-2962-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-020-2962-y