Abstract

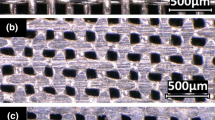

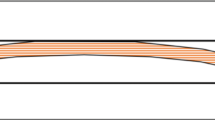

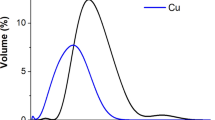

A spray coating technique is an excellent method for surface metallization and ceramic deposition to widen the application fields of irreplaceable engineering polymers. In this study, Al metallization and Al2O3 deposition on thermoplastic-polymers (polycarbonate, polyimide) and a thermosetting-polymer composite (carbon fiber reinforced epoxy) were conducted via atmospheric plasma spray (APS). Due to the susceptibility of polymers to thermal or mechanical damage, precise process control is required. It was shown that the engineering temperature range critically determines the process window of thermoplastic-polymers. An Al2O3 coating can be fabricated on polymers via an Al bond coat. Like a heat sink, the Al buffer layer enables polymers to endure process heating. In low thermally resistant polycarbonate (PC), only a low plasma energy source could be applied. Additionally, vaporization induced by Al droplet contact was a clear reason of the unstable weak interface between the coating and substrate. The coatings fabricated on polyimide (PI) substrates generally showed a continuous and clean interface with a moderate adhesion property. In the case of carbon fiber reinforced epoxy (CFRP), it is believed that carbon fibers acted as a heat sink such that considerable thermal damage of CFRP was not observed and there was not delamination of the coatings. However, fracturing of carbon fibers and epoxy resin by grit-blasting (surface pre-treatment) made the surface unstable. This led to the worst adhesion characteristics between the coating and CFRP substrate. It was demonstrated that because the available temperature range and surface condition are very sensitive compared to conventional metal substrates, advanced surface pre-treatment, precise process optimization, and additional cooling are required for successful deposition.

Graphic Abstract

Similar content being viewed by others

Reference

R. Dyson, Engineering Polymers (Springer Science & Business Media, Berlin, 1991), pp. 1–14

J. Pascault, H. Sautereau, J. Verdu, R. Williams, Thermosetting Polymers (CRC Press, Boca Raton, 2002), pp 1–4

V. Mittal, High Performance Polymers and Engineering Plastics (Wiley, New Jersey, 2011), pp 1–20

J. Davis, Handbook of Thermal Spray Technology (ASM international, Cleveland, 2004), pp 3–99

H. Che, X. Chu, P. Vo, S. Yue, Surf. Coat. Technol. 329, 232–243 (2017)

H. Che, P. Vo, S. Yue, Surf. Coat. Technol. 313, 236–247 (2017)

G. Bae, Y. Xiong, S. Kumar, K. Kang, C. Lee, Acta Mater. 56, 4858–4868 (2008)

M. Ivosevic, R. Knight, S. Kalidindi, G. Palmese, J. Sutter, J. Therm. Spray Technol. 14, 45–51 (2005)

J. Voyer, P. Schulz, M. Schreiber, J. Therm. Spray Technol. 17, 818–823 (2008)

W. Kim, A. Argento, P. Mohanty, J. Comp. Mater. 43, 277–287 (2009)

N. Bheekhun, A. Talib, M. Hassan, Int. Rev. Aerosp. Eng. 7, 84–87 (2014)

A. Rezzoug, S. Abdi, A. Kaci, M. Yandouzi, Surf. Coat. Technol. 333, 13–23 (2018)

A. Liu, M. Guo, J. Gao, M. Zhao, Surf. Coat. Technol. 201, 2696–2700 (2006)

S. Aruna, N. Balaji, J. Shedthi, V. Grips, Surf. Coat. Technol. 208, 92–100 (2012)

J. Li, H. Liao, C. Ding, C. Coddet, J. Mater. Process. Technol. 160, 34–42 (2005)

A. Reheem, A. Atta, M. Maksoud, Radiat. Phys. Chem. 127, 269–275 (2016)

Y. Tominaga, D. Shimamoto, Y. Hotta, Materials 11, 493 (2018)

M. Ivosevic, R. Knight, S. Kalidindi, G. Palmese, High Perform. Polym. 15, 503–517 (2003)

W. Huang, Y. Zhao, X. Fan, X. Meng, Y. Wang, X. Cai, X. Cao, Z. Wang, J. Therm. Spray Technol. 22, 918–925 (2013)

L. Zhu, W. Huang, H. Cheng, X. Cao, J. Therm. Spray Technol. 23, 1312–1322 (2014)

H. Abedi, M. Salehi, A. Shafyei, Surf. Coat. Technol. 337, 104–116 (2018)

R. Joven, R. Das, A. Ahmed, P. Roozbehja van, B. Minaie, in SAMPE International Symposium Proceedings, Charleston, South Carolina, January 2012

C. Li, B. Sun, Thin Solid Films 450, 282–289 (2004)

O. Sarikaya, Mater. Des. 26, 53–57 (2005)

S. Goel, S. Bjorklund, N. Curry, U. Wiklund, S. Joshi, Surf. Coat. Technol. 315, 80–87 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kwon, H., Kim, J. & Lee, C. Surface Metallization and Ceramic Deposition on Thermoplastic-Polymer and Thermosetting-Polymer Composite Via Atmospheric Plasma Spraying. Met. Mater. Int. 27, 3293–3306 (2021). https://doi.org/10.1007/s12540-020-00864-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00864-w