Abstract

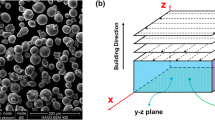

AISI 316L stainless steel samples were produced by means of laser powder-directed energy deposition using optimized building conditions with two different deposition strategies. The samples, in the as-built state, were at first characterized in terms of microstructure, hardness and residual stresses by the incremental hole-drilling strain-gauge method. The results highlighted that the deposition strategy mainly affects the residual stress values, while the material hardness value is not strongly varied. The distribution of the residual stresses along the sample height was also evaluated by measuring the stress at different distances from the building platform. Furthermore, some samples underwent a homogenizing heat treatment for 2 h at 600 and 800 °C and were characterized and compared with the as-built ones. The results showed that the suggested heat treatments allow not only a reduction in residual stresses but also the homogenization of the microstructure confirmed by comparing the variations of the Vickers hardness values along the building direction. Tensile tests were also performed on the as-built and heat-treated samples in order to investigate the effect of the heat treatment on the tensile properties of the material.

Similar content being viewed by others

References

M. Javidani, J. Arreguin-Zavala, J. Danovitch, Y. Tian, and M. Brochu, Additive Manufacturing of AlSi10Mg Alloy Using Direct Energy Deposition: Microstructure and Hardness Characterization, J. Therm. Spray Technol., 2017, 26(4), p 587–597

G. Marchese, X. Garmendia Colera, F. Calignano, M. Lorusso, S. Biamino, P. Minetola, and D. Manfredi, Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition, Adv. Eng. Mater., 2017, 19(3), p 1600635

G. Piscopo, E. Atzeni, F. Calignano, M. Galati, L. Iuliano, P. Minetola, and A. Salmi, Machining Induced Residual Stresses in AlSi10Mg Component Produced by Laser Powder Bed Fusion (L-PBF), Procedia CIRP, 2019, 79, p 101–106

L. Weiss, P. Acquier, L. Germain, and E. Fleury, Microtexture of Ti6Al4V Obtained by Direct Energy Deposition (DED) Process, in Proceedings of the 13th World Conference on Titanium, 2016, John Wiley & Sons, Inc., pp. 1305–1310

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi, and P. Fino, Microstructure and Mechanical Properties of AISI, 316L Produced by Directed Energy Deposition-Based Additive Manufacturing: A Review, Appl. Sci., 2020, 10(9), p 3310

A. Yadollahi, N. Shamsaei, S.M. Thompson, and D.W. Seely, Effects of Process Time Interval and Heat Treatment on the Mechanical and Microstructural Properties of Direct Laser Deposited 316L Stainless Steel, Mater. Sci. Eng. A, 2015, 644, p 171–183

P. Guo, B. Zou, C. Huang, and H. Gao, Study on Microstructure, Mechanical Properties and Machinability of Efficiently Additive Manufactured AISI, 316L Stainless Steel by High-Power Direct Laser Deposition, J. Mater. Process. Technol., 2017, 240, p 12–22

P. Köhnen, M. Letang, M. Voshage, J.H. Schleifenbaum, and C. Haase, Understanding the Process-Microstructure Correlations for Tailoring the Mechanical Properties of L-PBF Produced Austenitic Advanced High Strength Steel, Addit. Manuf., 2019, 30, p 100914

M.E. Stender, L.L. Beghini, J.D. Sugar, M.G. Veilleux, S.R. Subia, T.R. Smith, C.W. San Marchi, A.A. Brown, and D.J. Dagel, A Thermal–Mechanical Finite Element Workflow for Directed Energy Deposition Additive Manufacturing Process Modeling, Addit. Manuf., 2018, 21, p 556–566

L. Wagner, Mechanical Surface Treatments on Titanium, Aluminum and Magnesium Alloys, Mater. Sci. Eng. A, 1999, 263(2), p 210–216

B. Vrancken, V. Cain, R. Knutsen, and J. Van Humbeeck, Residual Stress Via the Contour Method in Compact Tension Specimens Produced Via Selective Laser Melting, Scr. Mater., 2014, 87, p 29–32

P.J. Withers and H. Bhadeshia, Residual Stress. Part 2—Nature and Origins, Mater. Sci. Technol., 2001, 17(4), p 366–375

P. Mercelis and J.-P. Kruth, Residual Stresses in Selective Laser Sintering and Selective Laser Melting, Rapid Prototyp. J., 2006, 12(5), p 254–265

P. Rangaswamy, T. Holden, R. Rogge, and M. Griffith, Residual Stresses in Components Formed by the Laser Engineered Net Shaping (LENS®) Process, J. Strain Anal. Eng. Des., 2003, 38(6), p 519–527

P. Rangaswamy, M. Griffith, M. Prime, T. Holden, R. Rogge, J. Edwards, and R. Sebring, Residual Stresses in LENS® Components Using Neutron Diffraction and Contour Method, Mater. Sci. Eng. A, 2005, 399(1–2), p 72–83

W. Woo, D.-K. Kim, E.J. Kingston, V. Luzin, F. Salvemini, and M.R. Hill, Effect of Interlayers and Scanning Strategies on Through-Thickness Residual Stress Distributions in Additive Manufactured Ferritic-Austenitic Steel Structure, Mater. Sci. Eng. A, 2019, 744, p 618–629

A. Saboori, G. Piscopo, M. Lai, A. Salmi, and S. Biamino, An investigation on the effect of deposition pattern on the microstructure, mechanical properties and residual stress of 316L produced by Directed Energy Deposition, Mater. Sci. Eng. A, 2020, 780, p 139179

B.M. Morrow, T.J. Lienert, C.M. Knapp, J.O. Sutton, M.J. Brand, R.M. Pacheco, V. Livescu, J.S. Carpenter, and G.T. Gray, Impact of Defects in Powder Feedstock Materials on Microstructure of 304L and 316L Stainless Steel Produced by Additive Manufacturing, Metall. Mater. Trans. A, 2018, 49(8), p 3637–3650

A. Saboori, A. Aversa, F. Bosio, E. Bassini, E. Librera, M. De Chirico, S. Biamino, D. Ugues, P. Fino, and M. Lombardi, An investigation on the effect of powder recycling on the microstructure and mechanical properties of AISI, 316L produced by Directed Energy Deposition, Mater. Sci. Eng. A, 2019, 766, p 138360

J.-P. Kruth and P. Bleys, Measuring Residual Stress Caused by Wire EDM of Tool Steel, Int. J. Electr. Mach., 2000, 5, p 23–28

B. Ekmekci, Residual Stresses and White Layer in Electric Discharge Machining (EDM), Appl. Surf. Sci., 2007, 253(23), p 9234–9240

H. Bueckner, The Propagation of Cracks and the Energy of Elastic Deformation, Trans. ASME Ser. E, 1958, 80(6), p 1225–1230

P. Pagliaro, M. Prime, J. Robinson, B. Clausen, H. Swenson, M. Steinzig, and B. Zuccarello, Measuring Inaccessible Residual Stresses Using Multiple Methods and Superposition, Exp. Mech., 2011, 51(7), p 1123–1134

M. Strantza, B. Vrancken, M. Prime, C. Truman, M. Rombouts, D. Brown, P. Guillaume, and D. Van Hemelrijck, Directional and Oscillating Residual Stress on the Mesoscale in Additively Manufactured Ti-6Al-4V, Acta Mater., 2019, 168, p 299–308

G.S. Schajer, Practical Residual Stress Measurement Methods, Wiley, Hoboken, 2013

ASTM International, E837-13a Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method, ASTM International, West Conshohocken, PA, 2013, https://doi.org/10.1520/E0837-13A

ASTM International, E8/E8M-16ae1 Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA, 2016, https://doi.org/10.1520/E0008_E0008M-16AE01

D.-R. Eo, S.-H. Park, and J.-W. Cho, Inclusion Evolution in Additive Manufactured 316L Stainless Steel by Laser Metal Deposition Process, Mater. Des., 2018, 155, p 212–219

A. Aversa, A. Saboori, E. Librera, M. de Chirico, S. Biamino, M. Lombardi, and P. Fino, The Role of Directed Energy Deposition Atmosphere Mode on the Microstructure and Mechanical Properties of 316L Samples, Addit. Manuf., 2020, 34, p 101274

K. Saeidi, X. Gao, Y. Zhong, and Z.J. Shen, Hardened Austenite Steel with Columnar Sub-Grain Structure Formed by Laser Melting, Mater. Sci. Eng. A, 2015, 625, p 221–229

N. Yang, J. Yee, B. Zheng, K. Gaiser, T. Reynolds, L. Clemon, W. Lu, J. Schoenung, and E. Lavernia, Process–Structure–Property Relationships for 316L Stainless Steel Fabricated by Additive Manufacturing and Its Implication for Component Engineering, J. Therm. Spray Technol., 2017, 26(4), p 610–626

L. Mugwagwa, D. Dimitrov, S. Matope, and I. Yadroitsev, Investigation of the Effect of Scan Vector Length on Residual Stresses in Selective Laser Melting of Maraging Steel 300, S. Afr. J. Ind. Eng., 2019, 30(4), p 60–70

O. Salman, C. Gammer, A. Chaubey, J. Eckert, and S. Scudino, Effect of Heat Treatment on Microstructure And Mechanical Properties of 316L Steel Synthesized by Selective Laser Melting, Mater. Sci. Eng. A, 2019, 748, p 205–212

C. Elangeswaran, A. Cutolo, G.K. Muralidharan, C. de Formanoir, F. Berto, K. Vanmeensel, and B. Van Hooreweder, Effect of Post-Treatments on the Fatigue Behaviour of 316L Stainless Steel Manufactured by Laser Powder Bed Fusion, Int. J. Fatigue, 2019, 123, p 31–39

S. Leuders, T. Lieneke, S. Lammers, T. Tröster, and T. Niendorf, On the Fatigue Properties of Metals Manufactured by Selective Laser Melting—The Role of Ductility, J. Mater. Res., 2014, 29(17), p 1911–1919

Acknowledgments

The authors would like to acknowledge Dr. Erica Librera and Dr. Michele De Chirico from Prima Additive (a division of Prima Industrie S.p.A.) for the production of samples and for their support in the experimental activities. The authors would like also to appreciate the assistance provided by Dr. Fabio Cicala in data analyses.

Funding

This work has been partially supported by “Ministero dell’Istruzione, dell’Università e della Ricerca” Award “TESUN- 83486178370409 finanziamento Dipartimenti di Eccellenza CAP. 1694 TIT. 232 ART. 6”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aversa, A., Piscopo, G., Salmi, A. et al. Effect of Heat Treatments on Residual Stress and Properties of AISI 316L Steel Processed by Directed Energy Deposition. J. of Materi Eng and Perform 29, 6002–6013 (2020). https://doi.org/10.1007/s11665-020-05061-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05061-9