Abstract

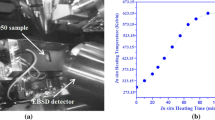

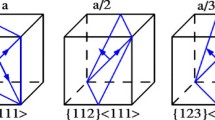

A Monte Carlo Potts model was developed to simulate the recrystallization process of a cold-rolled ultra-thin grain-oriented silicon steel. The orientation and image quality data from electron backscatter diffraction measurements were used as input information for simulation. Three types of nucleation mechanisms, namely, random nucleation, high-stored-energy site nucleation (HSEN), and high-angle boundary nucleation (HABN), were considered for simulation. In particular, the nucleation and growth behaviors of Goss-oriented ({011}<100>) grains were investigated. Results showed that Goss grains had a nucleation advantage in HSEN and HABN. The amount of Goss grains was the highest according to HABN, and it matched the experimental measurement. However, Goss grains lacked a size advantage across all mechanisms during the recrystallization process.

Similar content being viewed by others

References

S. Mishra, C. Därmann, and K. Lücke, On the development of the goss texture in iron-3% silicon, Acta Metall., 32(1984), No. 12, p. 2185.

K.I. Arai and K. Ishiyama, Rolled texture and magnetic properties of 3% silicon steel, J. Appl. Phys., 64(1988), No. 10, p. 5352.

T. Kubota, Recent progress on non-oriented silicon steel, Steel Res. Int., 76(2005), No. 6, p. 464.

X.H. Gao, K.M. Qi, and C.L. Qiu, Magnetic properties of grain oriented ultra-thin silicon steel sheets processed by conventional rolling and cross shear rolling, Mater. Sci. Eng. A, 430(2006), No. 1–2, p. 138.

H.Y. Song, H.T. Liu, Y.P. Wang, and G.D. Wang, Microstructure and texture evolution of ultra-thin grain-oriented silicon steel sheet fabricated using strip casting and three-stage cold rolling method, J. Magn. Magn. Mater., 426(2017), p. 32.

D. Dorner, S. Zaefferer, and D. Raabe, Retention of the Goss orientation between microbands during cold rolling of an Fe-3% Si single crystal, Acta Mater., 55(2007), No. 7, p. 2519.

J.T. Park and J.A. Szpunar, Evolution of recrystallization texture in nonoriented electrical steel, Acta Mater., 51(2003), No. 11, p. 3037.

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, Oxford, Netherlands, 2004.

D.J. Srolovitz, G.S. Grest, and M.P. Anderson, Computer simulation of recrystallization-I. Homogeneous nucleation and growth, Acta Metall., 34(1986), No. 9, p. 1833.

Y. Liu, T. Baudin, and R. Penelle, Simulation of normal grain growth by cellular automata, Scripta Mater., 34(1996), No. 11, p. 1679.

C.E. Krill Iii and L.Q. Chen, Computer simulation of 3-D grain growth using a phase-field model, Acta Mater., 50(2002), No. 12, p. 3059.

D. Raabe and R.C. Becker, Coupling of a crystal plasticity finite-element model with a probabilistic cellular automaton for simulating primary static recrystallization in aluminium, Modell. Simul. Mater. Sci. Eng., 8(2000), No. 4, p. 445.

D.N. Fan and L.Q. Chen, Diffusion-controlled grain growth in two-phase solids, Acta Mater., 45(1997), No. 8, p. 3297.

D.Q. Xin, C.X. He, X.H. Gong, H. Wang, L. Meng, G. Ma, P.F. Hou, and W.K. Zhang, Monte Carlo study on abnormal growth of Goss grains in Fe-3%Si steel induced by second-phase particles, Inter. J. Miner. Metall. Mater., 23(2016), No. 12, p. 1397.

Y.B. Chun, S.L. Semiatin, and S.K. Hwang, Monte Carlo modeling of microstructure evolution during the static recrystallization of cold-rolled, commercial-purity titanium, Acta Mater., 54(2006), No. 14, p. 3673.

D.E. Solas, C.N. Tomé, O. Engler, and H.R. Wenk, Deformation and recrystallization of hexagonal metals: Modeling and experimental results for zinc, Acta Mater., 49(2001), No. 18, p. 3791.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett, Current issues in recrystallization: A review, Mater. Sci. Eng. A, 238(1997), No. 2, p. 219.

J.Y. Kang, B. Bacroix, H. Réglé, K.H. Oh, and H.C. Lee, Effect of deformation mode and grain orientation on misorientation development in a body-centered cubic steel, Acta Mater., 55(2007), No. 15, p. 4935.

N. Rajmohan, Y. Hayakawa, J.A. Szpunar, and J.H. Root, Neutron diffraction method for stored energy measurement in interstitial free steel, Acta Mater., 45(1997), No. 6, p. 2485.

D.J. Srolovitz, G.S. Grest, M.P. Anderson, and A.D. Rollett, Computer simulation of recrystallization-II. Heterogeneous nucleation and growth, Acta Metall., 36(1988), No. 8, p. 2115.

F.J. Humphreys, Nucleation in recrystallization, Mater. Sci. Forum, 467–470(2004), No. 1, p. 107.

W.T. Read and W. Shockley, Dislocation models of crystal grain boundary, Phys. Rev., 78(1950), No. 3, p. 275.

P.A. Beck and P.R. Sperry, Strain induced grain boundary migration in high purity aluminum, J. Appl. Phys., 21(1950), No. 2, p. 150.

F. Lin, A. Godfrey, M.A. Miodownik, and Q. Liu, Monte Carlo modeling of cube texture evolution in Ni-tapes during grain growth, Mater. Sci. Forum, 467–470(2004), p. 1075.

A.D. Rollett, D.J. Srolovitz, R.D. Doherty, and M.P. Anderson, Computer simulation of recrystallization in non-uniformly deformed metals, Acta Metall., 37(1989), No. 2, p. 627.

Acknowledgement

The authors acknowledge the financial support from the National Key Research and Development Program of China (No. 2017YFB0903901).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Meng, L., Liu, Jm., Zhang, N. et al. Simulation of recrystallization based on EBSD data using a modified Monte Carlo model that considers anisotropic effects in cold-rolled ultra-thin grain-oriented silicon steel. Int J Miner Metall Mater 27, 1251–1258 (2020). https://doi.org/10.1007/s12613-020-2102-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2102-4