Abstract

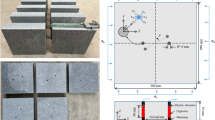

In a rock mass, holes of various sizes and geometries naturally occur, which in turn can affect the mechanical properties of the rock mass. These defects often cause engineering problems in subsurface construction. In this study, PFC2D was used to perform uniaxial compression tests on a rock mass containing ten different types of hole defects to analyze their failure behavior and mechanical properties. Four failure modes were determined, and crack propagation and stress field evolution were studied. The results show that the hole defect reduces the uniaxial compressive strength, peak strain, and elastic modulus of a rock mass. Also, these defects accelerate the generation of cracks and promote the destruction of the rock. The failure modes can be classified as Y-type, inverted Y-type, upper left to lower right type, and upper right to lower left type. Before cracks are generated, the compressive stress concentration area is located on the left and right sides of the hole and distributed as a butterfly shape, and the tensile stress concentration area is located in the upper and lower parts of the hole. A zone where stress is decreasing is located near the tip of the tensile stress triangular area. The magnitude and concentration area of compressive and tensile stresses are greatly affected by various hole geometries. Finally, the maximum principal compressive stress decreases instantly after a crack coalesces. Overall, the hole shape has a noticeable influence on the stress distribution surrounding the hole, and a hole defect reduces the degree of failure of a rock mass.

Similar content being viewed by others

References

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min Sci 35(7):863–888

Cao P, Liu TY, Pu CZ, Lin H (2015) Crack propagation and coalescence of brittle rock-like specimens with preexisting cracks in compression. Eng Geol 187:113–121

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44:997–1010

Cundall PA, Strack OD (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Feng F, Chen SJ, Li DY, Hu ST, Huang WP, Li B (2019) Analysis of fractures of a hard rock specimen via unloading of central hole with different sectional shapes. Energy Sci Eng 2019(00):1–22

Fu JW, Chen K, Zhu WS, Zhang XZ, Li XJ (2016) Progressive failure of new modelling material with a single internal crack under biaxial compression and the 3-D numerical simulation. Eng Fract Mech 165:140–152

Gui YL, Zhao ZY, Zhang C, Ma SQ (2017) Numerical investigation of the opening effect on the mechanical behaviours in rocks under uniaxial loading using hybrid continuum-discrete element method. Comput Geotech 90:55–72

Hadi H, Vahab S, Zhu ZM, Mohammad FM (2018) Simulating the influence of pore shape on the Brazilian tensile strength of concrete specimens using PFC2D. Comput Concr 22(5):469–479

Hadi H, Vahab S, Zhu ZM, Mohammad FM (2019) Experimental and numerical studies of the pre-existing cracks and pores interaction in concrete specimens under compression. Smart Struct Syst 23(5):479–493

Huang YH, Yang SQ (2019) Mechanical and cracking behavior of granite containing two coplanar flaws under conventional triaxial compression. Int J Damage Mech 28(4):590–610

Huang D, Cen DF, Huang RQ (2013) Moderate strain rate effect particle flow simulation of single fractured sandstone under uniaxial compression. Rock Soil Mech 34(2):536–545

Huang D, Gu DM, Yang C, Huang RQ, Fu GY (2016) Investigation on mechanical behaviors of sandstone with two preexisting flaws under triaxial compression. Rock Mech Rock Eng 49:375–399

Huang YH, Yang SQ, Ranjith PG, Zhao J (2017) Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: experimental study and particle flow modeling. Comput Geotech 88:182–198

Huang YH, Yang SQ, Tian WL (2019) Crack coalescence behavior of sandstone specimen containing two pre-existing flaws under different confining pressures. Theor Appl Fract Mech 99:118–130

International Society for Rock Mechanics (ISRM) (1981) Suggested methods for the quantitative description of discontinuities in rock masses. In: Brown ET (ed) Rock characterization, testing and monitoring-ISRM suggested methods. Pergamon Press, Oxford, pp 3–52

Lee H, Seokwon J (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999

Li HQ, Wong LNY (2012) Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int J Solids Struct 49(18):2482–2499

Li HQ, Wong LNY (2013) Numerical study on coalescence of preexisting flaw pairs in rock-like material. Rock Mech Rock Eng 47(6):2087–2105

Li DY, Zhu QQ, Zhou ZL, Li XB, Ranjith PG (2017) Fracture analysis of marble specimens with a hole under uniaxial compression by digital image correlation. Eng Fract Mech 183:109–124

Liang ZZ, Xing H, Wang SY, Williams DJ, Tang CA (2012) A three-dimensional numerical investigation of the fracture of rock specimens containing a preexisting surface flaw. Comput Geotech 19:33–45

Lin P, Zhou YN, Liu HY, Wang C (2013) Reinforcement design and stability analysis for large-span tailrace bifurcated tunnels with irregular geometry. Tunn Undergr Space Technol 38(2013):189–204

Lin P, Wong RHC, Tang CA (2015) Experimental study of coalescence mechanisms and failure under uniaxial compression of granite containing multiple holes. Int J Rock Mech Min Sci 77:313–327

Lisjak A, Grasselli G (2014) A review of discrete modeling techniques for fracturing processes in discontinuous rock mass. J Rock Mech Geotech Eng 6:301–314

Liu T, Lin BQ, Yang W (2017) Mechanical behavior and failure mechanism of pre-cracked specimen under uniaxial compression. Tectonophysics 712-713:330–343

Liu XR, Yang SQ, Huang YH, Cheng JL (2019) Experimental study on the strength and fracture mechanism of sandstone containing elliptical holes and fissures under uniaxial compression. Eng Fract Mech 205:205–217

Morgan SP, Einstein HH (2017) Cracking processes affected by bedding planes in Opalinus shale with flaw pairs. Eng Fract Mech 176:213–234

Park CH, Bobet A (2009) Crack coalescence in specimens with open and closed flaws: a comparison. Int J Rock Mech Min Sci 46(5):819–829

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Robina HC. Wong KT. Chau (1998) Crack coalescence in a rock-like material containing two cracks. Int J Rock Mech Min Sci 35(2):147–164

Tang CA, Lin P, Wong RHC, Chau KT (2001) Analysis of crack coalescence in rock-like materials containing three flaws-part II: numerical approach. Int J Rock Mech Min Sci 38(7):925–939

Vahab S, Hadi H, Alireza BS (2018) Simulation of fracture mechanism of pre-holed concrete model under Brazilian test using PFC3D. Smart Struct Syst 22(6):675–687

Wang J, Zhang Y, Qin Z, Song SG, Lin P (2020) Analysis method of water inrush for tunnels with damaged water-resisting rock mass based on finite element method-smooth particle hydrodynamics coupling. Comput Geotech 126(2020):103725. https://doi.org/10.1016/j.compgeo.2020.103725

Wong LNY, Einstein HH (2009) Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int J Rock Mech Min Sci 46(2):239–249

Wong RHC, Lin P (2015) Numerical study of stress distribution and crack coalescence mechanisms of a solid containing multiple holes. Int J Rock Mech Min Sci 79:41–54

Yang SQ (2011) Crack coalescence behavior of brittle sandstone samples containing two coplanar fissures in the process of deformation failure. Eng Fract Mech 78(17):3059–3081

Yang SQ, Liu XR, Li YS (2012a) Experimental analysis of mechanical properties of sandstone with holes and fractures under uniaxial compression. Chin J Rock Mech Eng 31(Supp.2):3539–3546

Yang SQ, Yang DS, Jing HW, Li YH, Wang SY (2012b) An experimental study of the fracture coalescence behaviour of brittle sandstone specimens containing three fissures. Rock Mech Rock Eng 45(4):563–582

Yang SQ, Tian WL, Huang YH, Ma ZG, Fan LF, Wu ZJ (2018) Experimental and discrete element modeling on cracking behavior of sandstone containing a single oval flaw under uniaxial compression. Eng Fract Mech 194:154–174

Yang WD, Luo GY, Duan K, Jing WJ, Zhang LZ, Wang SG, Zhao Y (2019) Development of a damage rheological model and its application in the analysis of mechanical properties of jointed rock mass. Energy Sci Eng 7(3):1016–1031

Zhao JH, Zhang XG, Jiang N, Yin LM, Guo WJ (2020) Porosity zoning characteristics of fault floor under fluid-solid coupling. Bull Eng Geol Environ 79(5):2529–2541

Zhou XP, Bi J, Qian QH (2015) Numerical simulation of crack growth and coalescence in rock-like materials containing multiple preexisting flaws. Rock Mech Rock Eng 48(3):1097–1114

Zhu QQ, Li DY, Han ZY, Li XB, Zhou ZL (2019) Mechanical properties and fracture evolution of sandstone specimens containing different inclusions under uniaxial compression. Int J Rock Mech Min Sci 115:33–47

Funding

This study was supported by the National Natural Science Foundation of China (51474134, 51774194), Shandong Provincial Natural Science Foundation for Distinguished Young Scholars (JQ201612), Major Basic Research Projects of Shandong Natural Science Foundation (ZR2018ZC07 40), and Taishan Scholar Talent Team Support Plan for Advantaged & Unique Discipline Areas.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S., Xia, Z., Feng, F. et al. Numerical study on strength and failure characteristics of rock samples with different hole defects. Bull Eng Geol Environ 80, 1523–1540 (2021). https://doi.org/10.1007/s10064-020-01964-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-01964-y