Abstract

The use of printed circuit boards (PCBs) has become essential in manufacturing parts with electronic functions. However, the placement of PCBs inside a product requires special plates or fixtures that need to be separately designed, fabricated, and assembled. In addition, PCB manufacturing generally utilizes various toxic metals and etchants. Thus, there is a need to address the issues of space, cost, and environmental toxicity inherent in PCBs. This paper proposes a novel method of fabricating PCB-free part with electronic circuits in a set using the casing or exterior of a product. This process enables the manufacturing of a type of molded interconnect device without conventional molding technologies by directly forming conductive circuits on the side or back of 3D-printed substrates using selective electroless plating. For 3D printing of the product structure, this study uses substrates made of polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS), which are commonly used in the popular material-extrusion 3D printing technology. As ABS and PLA have different chemical properties, the region to be plated with the electrical circuit is fabricated using ABS, whereas the remaining substrate is fabricated using PLA. ABS was chemically treated to allow electroless plating. A process for forming 3D circuits was developed and evaluated by selective electroless plating of the areas of the substrate requiring circuitry. To verify the applicability of the proposed process, circuits and integrated parts used in the industry were redesigned into a single component and fabricated by applying the proposed process. The results demonstrate that the proposed process has good practical applicability. Furthermore, it has low environmental toxicity with low requirements for material consumption and processing energy.

Similar content being viewed by others

References

Yung, K. C., Liem, H., Choy, H. S., & Lun, W. K. (2010). Thermal performance of high brightness LED array package on PCB. International Communications in Heat and Mass Transfer, 37(9), 1266–1272.

Chen, M., Ogunseitan, O. A., Wang, J., Chen, H., Wang, B., & Chen, S. (2016). Evolution of electronic waste toxicity: Trends in innovation and regulation. Environment International, 89–90, 147–154.

Kang, M., & Kang, K. (2018). Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics. International Journal of Precision Engineering and Manufacturing-Green Technology, 5, 421–426.

Lee, J., Kim, H., Choi, J., & Lee, I. (2017). A review on 3D printed smart devices for 4D printing. International Journal of Precision Engineering and Manufacturing-Green Technology, 4, 373–383.

Lu, Y., Yun, H., Vatani, M., Kim, H., & Choi, J. (2015). Direct-print/cure as a molded interconnect device (MID) process for fabrication of automobile cruise controllers. Journal of Mechanical Science and Technology, 29, 5377–5385.

Yun, H., Kim, H., & Lee, I. (2017). Research of circuit manufacturing for new MID technology development. Journal of Mechanical Science and Technology, 31, 5737–5743.

Ko, H.-J. (2014). Development of 3D MID(Molded Interconnect Device) cruise control switch. Master thesis, Department of Mechanical Engineering Graduate School, Andong National University.

Lim, S.-G. (2016). Research for generating circuit pattern of three-dimensional plastic (ABS) structure. Master thesis, Department of Mechanical Engineering Graduate School, Andong National University.

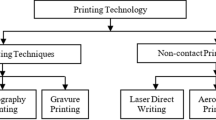

Hon, K. K. B., Li, L., & Hutching, I. M. (2008). Direct Writing technology—Advances and developments. CIRP Annals, 57(2), 601–620.

Kim, N.S., Han, K.N., Church, & KH. (2007). Direct Writing Technology for 21st Century Industries -Focus on Micro-Dispensing Deposition Write Technology. In: KSMTE Annual Spring Conference 2007, pp. 511–515.

Ren, L., Li, B., Song, Z., Liu, L., Ren, L., & Zhou, X. (2019). 3D printing of bioinspired structural materials with fibers induced by doctor blading process. International Journal of Precision Engineering and Manufacturing-Green Technology, 6, 89–99. https://doi.org/10.1007/s40684-019-00030-7.

Alkadi, F., Lee, J., Yeo, J., Hwang, S., & Choi, J. (2019). 3D printing of ground tire rubber composites. International Journal of Precision Engineering and Manufacturing-Green Technology, 6, 211–222. https://doi.org/10.1007/s40684-019-00023-6.

Hu, F., Lyu, L., & He, Y. (2019). A 3D printed paper-based thermally driven soft robotic gripper inspired by cabbage. International Journal of Precision Engineering and Manufacturing, 20, 1915–1928. https://doi.org/10.1007/s12541-019-00199-6.

Liu, J., Zheng, Y., Ma, Y., Qureshi, A., & Ahmad, R. (2019). A topology optimization method for hybrid subtractive-additive remanufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-019-00075-8.

Kim, H., Cha, M., Kim, B., Lee, I., & Mun, D. (2019). Maintenance framework for repairing partially damaged parts using 3D printing. International Journal of Precision Engineering and Manufacturing, 20, 1451–1464. https://doi.org/10.1007/s12541-019-00132-x.

Chung, H., Lee, N., Ko, J., Lee, T., & Lee, P. (2019). Optimal powder deposition process to develop a new direct-write additive manufacturing system. International Journal of Precision Engineering and Manufacturing, 20, 1057–1067. https://doi.org/10.1007/s12541-019-00129-6.

Nguyen, C. H. P., Kim, Y., & Choi, Y. (2019). Design for additive manufacturing of functionally graded lattice structures: a design method with process induced anisotropy consideration. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-019-00173-7.

Lee, D., Kim, H., Sim, J., Lee, D., Cho, H., & Hong, D. (2019). Trends in 3D printing technology for construction automation using text mining. International Journal of Precision Engineering and Manufacturing, 20, 871–882. https://doi.org/10.1007/s12541-019-00117-w.

Kim, H., Park, S., & Lee, I. (2019). Additive manufacturing of smart insole by direct printing of pressure sensitive material. Journal of Mechanical Science and Technology, 33, 5609–5614. https://doi.org/10.1007/s12206-019-1101-8.

Jeon, S., Han, J., Jeong, W., Son, J., & Kim, J. (2019). Flexibility enhancement of poly(lactide-co-glycolide) for fused deposition modeling technology. International Journal of Precision Engineering and Manufacturing-Green Technology, 6, 465–475. https://doi.org/10.1007/s40684-019-00067-8.

Günay, E. E., Velineni, A., Park, K., & Kremer, G. (2019). An investigation on process capability analysis for fused filament fabrication. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-019-00298-4.

Kim, M. K., Lee, I. H., & Kim, H. (2018). Effect of fabrication parameters on surface roughness of FDM parts. International Journal of Precision Engineering and Manufacturing, 19, 137–142. https://doi.org/10.1007/s12541-018-0016-0.

Beak, B. M., Lee, J. H., Shin, D. S., & Lee, K. S. (2012). Development of three dimensions laser direct patterning system. Journal of the KSMTE, 21(1), 116–122.

Lee, I. K. (2004). A study on the Ni UBM using electroless Ni plating method. Master thesis, School of Material Engineering, Seoul National University.

Hong, M. S. (2012). Mechanical properties and electromagnetic interference shielding behaviors of electroless nickel-loaded multi-walled carbon nanotube/chopped fibers-reinforced high density poly ethylene matrix composites. Master thesis Department of Nano Advanced Materials, Jeonju University.

Tang, X., Cao, M., Bi, C., Yan, L., & Zhang, B. (2008). Research on a new surface activation process for electroless plating on ABS plastic. Materials Letters, 62(6–7), 1089–1091.

Olivera, S., Muralidhara, H. B., Venkatesh, K., Gopalakrishna, K., & Vivek, C. S. (2016). Plating on acrylonitrile–butadiene–styrene (ABS) plastic: a review. Journal of Materials Science, 51, 3657–3674.

Haque, I.-U., Ahmad, S., & Khan, A. (2005). Electroless nickel plating on ABS plastics from nickel chloride and nickel sulfate baths. Journal Chemical Society of Pakistan, 27(3), 246–249.

Kim, S. Y. (2018). 3D circuit device by selective plating of 3D printing parts. Master thesis, Department of Mechanical Engineering Graduate School, Andong National University.

Acknowledgement

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (NRF-2017R1A2B4009386)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, S., Lee, I. & Kim, H. Fabrication of Parts with Integrated Circuits by Selective Electroless Plating of Additively Manufactured Plastic Substrates. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 1439–1447 (2021). https://doi.org/10.1007/s40684-020-00252-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-020-00252-0