Abstract

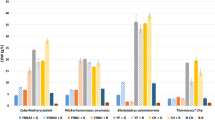

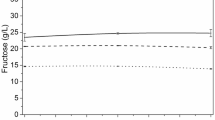

n-Butanol is a renewable resource with a wide range of applications. Its physicochemical properties make it a potential substitute for gasoline. Saccharomyces cerevisiae can produce n-butanol via amino acid catabolic pathways, but the use of pure amino acids is economically unfeasible for large-scale production. The aim of this study was to optimize the production of n-butanol by S. cerevisiae from protein-rich agro-industrial by-products (sunflower and poultry offal meals). By-products were characterized according to their total protein and free amino acid contents and subjected to enzymatic hydrolysis. Protein hydrolysates were used as nitrogen sources for the production of n-butanol by S. cerevisiae, but only poultry offal meal hydrolysate (POMH) afforded detectable levels of n-butanol. Under optimized conditions (carbon/nitrogen ratio of 2 and working volume of 60%), 59.94 mg/L of n-butanol was produced using POMH and glucose as substrates. The low-cost agro-industrial by-product showed great potential to be used in the production of n-butanol by S. cerevisiae. Other protein-rich residues may also find application in biofuel production by yeasts.

Similar content being viewed by others

References

Chen CT, Liao JC (2016) Frontiers in microbial 1-butanol and isobutanol production. FEMS Microbiol Lett 363:1–13. https://doi.org/10.1093/femsle/fnw020

Branduardi P, Porro D (2016) n-butanol: challenges and solutions for shifting natural metabolic pathways into a viable microbial production. FEMS Microbiol Lett 363:1–7. https://doi.org/10.1093/femsle/fnw070

Kuroda K, Ueda M (2016) Cellular and molecular engineering of yeast Saccharomyces cerevisiae for advanced biobutanol production. FEMS Microbiol Lett 363:1–24. https://doi.org/10.1093/femsle/fnv247

Choi YJ, Lee J, Jang YS, Lee SY (2014) Metabolic engineering of microorganisms for the production of higher alcohols. mBio 5:1–10. https://doi.org/10.1128/mBio.01524-14

Swidah R, Wang H, Reid PJ et al (2015) Butanol production in S. cerevisiae via a synthetic ABE pathway is enhanced by specific metabolic engineering and butanol resistance. Biotechnol Biofuels 8:97. https://doi.org/10.1186/s13068-015-0281-4

Steen EJ, Chan R, Prasad N, Myers S, Petzold CJ, Redding A, Ouellet M, Keasling JD (2015) Metabolic engineering of Saccharomyces cerevisiae for the production of n-butanol. Microb Cell Factories 7:36. https://doi.org/10.1186/1475-2859-7-36

Jiang Y, Liu J, Jiang W, Yang Y, Yang S (2014) Current status and prospects of industrial bio-production of n-butanol in China. Biotechnol Adv 33:1493–1501. https://doi.org/10.1016/j.biotechadv.2014.10.007

Si T, Luo Y, Xiao H, Zhao H (2014) Utilizing an endogenous pathway for 1-butanol production in Saccharomyces cerevisiae. Metab Eng 22:60–68. https://doi.org/10.1016/j.ymben.2014.01.002

Shi S, Si T, Liu Z, Zhang H, Ang EL, Zhao H (2016) Metabolic engineering of a synergistic pathway for n-butanol production in Saccharomyces cerevisiae. Sci Rep 6:25675. https://doi.org/10.1038/srep25675

Hazelwood LA, Daran JM, van Maris AJ et al (2008) The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Appl Environ Microbiol 74:2259–2266. https://doi.org/10.1128/AEM.02625-07

Branduardi P, Longo V, Berterame NM, Rossi G, Porro D (2013) A novel pathway to produce butanol and isobutanol in Saccharomyces cerevisiae. Biotechnol Biofuels 6:68. https://doi.org/10.1186/1754-6834-6-68

Schmidt CG, Salas-Mellado M (2009) Influence of alcalase and flavourzyme performance on the degree of hydrolysis of the proteins of chicken meat. Quím Nova 32:1144–1150. https://doi.org/10.1590/S0100-40422009000500012

Choi KY, Wernick DG, Tat CA, Liao JC (2014) Consolidated conversion of protein waste into biofuels and ammonia using Bacillus subtilis. Met Eng 23:53–61. https://doi.org/10.1016/j.ymben.2014.02.007

Furlani IL, Amaral BS et al (2020) Imobilização enzimática: Conceito e efeitos na proteólise. Quím Nova:1–11. https://doi.org/10.21577/0100-4042.20170525

Rodrigues MI, Iemma AF (2014) Experimental design and process optimization. CRC Press

Barbosa R, Almeida P, Safar SVB, Santos RO, Morais PB, Nielly-Thibault L, Leducq JB, Landry CR, Gonçalves P, Rosa CA, Sampaio JP (2016) Evidence of natural hybridization in Brazilian wild lineages of Saccharomyces cerevisiae. Genome Biol Evol 8:317–329. https://doi.org/10.1093/gbe/evv263

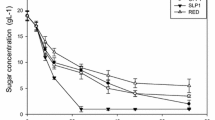

Azambuja SPH, Teixeira GS, Andrietta MGS, Torres-Mayanga PC, Forster-Carneiro T, Rosa CA, Goldbeck R (2019) Analysis of metabolite profiles of Saccharomyces cerevisiae strains suitable for butanol production. FEMS Microbiol Lett 366:1–7. https://doi.org/10.1093/femsle/fnz164

Instituto Adolfo Lutz (2008) Métodos físico-químicos para análise de alimentos, São Paulo 4:-1020

White JA, Hart RJ, Fry JC (1986) An evaluation of the waters Pico-tag system for the amino-acid analysis of food materials. J Anal Met Chem 8:170–177. https://doi.org/10.1155/S1463924686000330

Hagen SR, Frost B, Augustin J (1989) Precolumn phenylisothiocyanate derivatization and liquid chromatography of amino acids in food. J Assoc Off Anal Chem 72:912–916. https://doi.org/10.1016/0308(93)90-8146127-2

Spies JR (1967) Determination of tryptophan in proteins. Anal Chem 39:1412–1416. https://doi.org/10.1021/ac60256a004

Kurozawa LE, Park KJ, Hubinger MD (2009) Influência das condições de processo na cinética de hidrólise enzimática de carne de frango. Ciênc Tecnol Aliment 29:557–566. https://doi.org/10.1590/S0101-20612009000300017

Steinhardt J, Beychok S (1964) Interaction of proteins with hydrogen ions and other small ions and molecules. The Proteins: Composition, Structure and Function 2:139–304

Kristinsson HG, Rasco BA (2000) Kinetics of the hydrolysis of Atlantic salmon (Salmo salar) muscle proteins by alkaline proteases and a visceral serine protease mixture. Process Biochem 36:131–139. https://doi.org/10.1016/S0032-9592(00)00195-3

Pastore GM, Bicas JL, Junior MRM (2013) Biotecnologia de alimentos. Atheneu, São Paulo

Tavernari FC, Albino LFT et al (2008) Farelo de girassol: composição e utilização na alimentação de frangos de corte. Rev Ele Nutr 5:638–647

Rostagno HS, Albino LT et al (2011) Brazilian tables for poultry and swine: composition of feedstuffs and nutritional requirements. UFV, DZO: Viçosa

Zarkadas CG, Yu Z, Voldeng HD, Hope HJ, Minero-Amador A, Rochemont JA (1994) Comparison of the protein-bound and free amino acid contents of two northern adapted soybean cultivars. J Agric Food Chem 42:21–33. https://doi.org/10.1021/jf00037a003

Yoshizawa K (1964) The formation of higher alcohols in the fermentation of amino acids by yeast: the formation of isobutanol from α-acetolactic acid by washed yeast cells. Agric Biol Chem 28:279–285. https://doi.org/10.1080/00021369.1964.10858244

Chen X, Nielsen KF, Borodina I, Kielland-Brandt MC, Karhumaa K (2011) Increased isobutanol production in Saccharomyces cerevisiae by overexpression of genes in valine metabolism. Biotechnol Biofuels 4:21. https://doi.org/10.1186/1754-6834-4-21

Villanueva A, Vioque J, Sánchez-Vioque R, Clemente A, Pedroche J, Bautista J, Millán F (1999) Peptide characteristics of sunflower protein hydrolysates. J Amer Oil Chem Soc 76:1455–1460. https://doi.org/10.1007/s11746-999-0184-2

Ordonez C, Benitez C, Gonzalez JL (2008) Amino acid production from a sunflower wholemeal protein concentrate. Bioresour Technol 99:4749–4754. https://doi.org/10.1016/j.biortech.2007.09.061

Taheri A, Kenari AA et al (2011) Poultry by-products and enzymatic hydrolysis: optimization by response surface methodology using Alcalase® 2.4 L. Inter J Food Eng 7(5). https://doi.org/10.2202/1556-3758.1969

Carrão-Panizzi MC, Mandarino JMG (1994) Girassol: derivados protéicos. Embrapa Soja-Documentos (INFOTECA-E)

Perry JR, Basrai MA, Steiner HY, Naider F, Becker JM (1994) Isolation and characterization of a Saccharomyces cerevisiae peptide transport gene. Mol Cell Biol 14:104–115. https://doi.org/10.1128/MCB.14.1.104

Huo YX, Cho KM, Rivera JGL, Monte E, Shen CR, Yan Y, Liao JC (2011) Conversion of proteins into biofuels by engineering nitrogen flux. Nat Biotech 29:346–351. https://doi.org/10.1038/nbt.1789

Gutierrez LE (1993) Produção de álcoois superiores por linhagens de Saccharomyces durante a fermentação alcoólica. Sci Agric 50:464–472. https://doi.org/10.1590/S0103-90161993000300021

Sentheshanmuganathan S, Elsden SR (1958) The mechanism of the formation of tyrosol by Saccharomyces cerevisiae. Biochem J 69:210–218. https://doi.org/10.1042/bj0690210

Serp D, von Stockar U, Marison IW (2003) Enhancement of 2-phenylethanol productivity by Saccharomyces cerevisiae in two-phase fed-batch fermentations using solvent immobilization. Biotechnol Bioeng 82:103–110. https://doi.org/10.1002/bit.10545

Äyrápáá T (1971) Biosynthetic formation of higher alcohols by yeast. Dependence on the nitrogenous nutrient level of the medium JI. Brewing 77:266–276. https://doi.org/10.1002/j.2050-0416.1971.tb06945.x

Atsumi S, Cann AF, Connor MR, Shen CR, Smith KM, Brynildsen MP, Chou KJY, Hanai T, Liao JC (2008) Metabolic engineering of Escherichia coli for 1-butanol production. Metab Eng 10:305–311. https://doi.org/10.1016/j.ymben.2007.08.003

Steen EJ, Chan R, Prasad N, Myers S, Petzold CJ, Redding A, Ouellet M, Keasling JD (2008) Metabolic engineering of Saccharomyces cerevisiae for the production of n-butanol. Microb Cell Factories 7:1–8. https://doi.org/10.1186/1475-2859-7-36

Funding

The authors thank the São Paulo State Research Foundation (FAPESP) for the financial support (grants nos. 2015/50612-8, 2015/20630-4, 2016/04602-3 and 2019/08542-3) and Dr. Maria Teresa Bertoldo Pacheco from the Institute of Food Technology, Campinas, Brazil, for kindly providing the sunflower meal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Eleni Gomes.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 280 kb)

Rights and permissions

About this article

Cite this article

Santos, B.A.S., Azambuja, S.P.H., Ávila, P.F. et al. n-Butanol production by Saccharomyces cerevisiae from protein-rich agro-industrial by-products. Braz J Microbiol 51, 1655–1664 (2020). https://doi.org/10.1007/s42770-020-00370-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-020-00370-6