Abstract

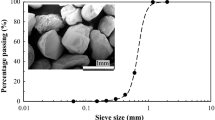

Cement stabilization is a useful and widely adopted method to improve the engineering properties of soils. However, characterization of the unconfined compressive strength, a simple and useful design property, is not straightforward due to complex interactions of various influence factors. This study investigated the effects of water content on the unconfined compressive strength of cement-stabilized clayey sands. The results show that the strength of the cemented binary mixtures increases with water content and water-to-cement ratio until a threshold value is reached and then decreases with further increase in water content and water-to-cement ratio. The unconfined compressive strength is correlated with ultrasonic wave velocity and shear wave velocity, respectively, showing two nearly unique correlations. Microscale analysis based on the coated sphere model revealed that the strength of the sample is affected by the bonding area and the strength of the binder material (cement–clay mixture). An empirical equation is also proposed based on the microscale analysis so as to capture the effects of water content on the strength.

Similar content being viewed by others

Data availability statement

All data, models, and code generated or used during the study appear in the submitted article.

Abbreviations

- A :

-

Fitting parameter

- a :

-

Radius of bonding area

- Cc, Cu :

-

Coefficient of curvature and uniformity, respectively

- cc:

-

Cement content

- D10, D50 :

-

Effective particle size and median particle size, respectively

- e :

-

Void ratio

- FC:

-

Fines content

- F unit :

-

External force exerted on a unit

- farea, fstrength :

-

Function to characterize bonding area and bonding strength, respectively

- (f + c)/s :

-

Mass ratio of fines and cement to sand particles

- G s :

-

Specific gravity

- Gs,cement, Gs,fines, Gs,sand :

-

Specific gravity of cement, fines, and sand particle, respectively

- H :

-

Sample height

- k :

-

A parameter representing the volumetric contribution of water to Vcoat

- m, n :

-

Fitting parameters

- OPC:

-

Ordinary Portland cement

- q uc :

-

Unconfined compressive strength

- R :

-

Radius of sphere

- SEM:

-

Scanning electron microscope

- t :

-

Thickness of coating

- UCS:

-

Unconfined compressive strength

- UPV:

-

Ultrasonic pulse velocity

- USCS:

-

Unified soil classification system

- Vcoat, Vcement, Vfines, Vsand, Vwater :

-

Volume of coating, cement, fines, sand particle, and water, respectively

- V s :

-

Shear wave velocity

- w/(c + f):

-

Mass ratio of water to cement and fines

- w/c :

-

Water-to-cement ratio

- (w/c)th :

-

Threshold water-to-cement ratio

- w L :

-

Liquid limit

- w soil :

-

Water content of soil

- w th :

-

Threshold water content

- α, β :

-

Fitting parameters

- γd, γsolid :

-

Unit weight of dry soil and solid, respectively

- λ :

-

Wavelength

- σunit, σbond :

-

Shearing resistance of the unit and bond, respectively

References

American Society for Testing and Materials (2013) Standard test method for unconfined compressive strength of cohesive soil. ASTMD2166/D2166M, West Conshohocken, PA

Bogas JA, Gomes MG, Gomes A (2013) Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 53(5):962–972

Cardoso R, Ribeiro D, Néri R (2017) Bonding effect on the evolution with curing time of compressive and tensile strength of sand–cement mixtures. Soils Found 57(4):655–668

Carraro JAH, Prezzi M, Salgado R (2009) Shear strength and stiffness of sands containing plastic or nonplastic fines. J Geotech Geoenviron Eng 135(9):1167–1178

Chang TP, Lin HC, Chang WT, Hsiao JF (2006) Engineering properties of lightweight aggregate concrete assessed by stress wave propagation methods. Cement Concrete Comp 28(1):57–68

Clough GW, Iwabuchi J, Rad NS, Kuppusamy T (1989) Influence of cementation on liquefaction of sands. J Geotech Eng 115(8):1102–1117

Consoli NC, Foppa D, Festugato J, Heineck KS (2007) Key Parameters for strength control of artificially cemented soils. J Geotech Geoenviron Eng 133(2):197–205

Consoli NC, Dalla Rosa F, Fonini A (2009) Plate load tests on cemented soil layers overlaying weaker soil. J Geotech Geoenviron Eng 135(12):1846–1856

Consoli NC, Cruz RC, Floss MF (2011) Variables controlling strength of artificially cemented sand: influence of curing time. J Mater Civ Eng 23(5):692–696

Fernandes VA, Purnell P, Still GT, Thomas TH (2007) The effect of clay content in sands used for cementitious materials in developing countries. Cement Concrete Res 37(5):751–758

Fernandez AL, Santamarina JC (2001) Effect of cementation on the small-strain parameters of sands. Can Geotech J 38(1):191–199

Davidson DT, Pitre GL, Mateos M, George, KP (1962) Moisture-density, moisture-strength and compaction characteristics of cement-treated soil mixtures. In: Proceedings of the 41 annual meet highway Res Board. Highway Research Board, Washington, DC, pp 42–63

Ho LS, Nakarai K, Duc M, Le Kouby A, Maachi A, Sasaki T (2018) Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr Build Mater 166:634–646

Horpibulsuk S, Miura N, Nagaraj TS (2003) Assessment of strength development in cement-admixed high water content clays with Abrams’ law as a basis. Géotechnique 53(4):439–444

Horpibulsuk S, Rachan R, Chinkulkijniwat A, Raksachon Y, Suddeepong A (2010) Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr Build Mater 24(10):2011–2021

Kaniraj SR, Havanagi VG (1999) Compressive strength of cement stabilized fly ash–soil mixtures. Cement Concrete Res 29(5):673–677

Khan Z, Majid A, Cascante G, Hutchinson DJ, Pezeshkpour P (2006) Characterization of a cemented sand with the pulse-velocity method. Can Geotech J 43(3):294–309

Khan Q, Subramanian S, Wong DYC, Ku T (2019) Bender elements in stiff cemented clay: shear wave velocity (Vs) correction by applying wavelength considerations. Can Geotech J 56(7):1034–1041

Khan Q, Moon SW, Ku T (2020) Idealized sine wave approach to determine arrival times of shear wave signals using bender elements. Geotech Test J 43:171–193

Ladd R (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23

Lee F-H, Lee Y, Chew S-H, Yong K-Y (2005) Strength and modulus of marine clay–cement mixes. J Geotech Geoenviron Eng 131(2):178–186

Liu Y, He LQ, Jiang YJ, Sun MM, Chen EJ, Lee F-H (2019) Effect of in situ water content variation on the spatial variation of strength of deep cement-mixed clay. Géotechnique 69(5):391–405

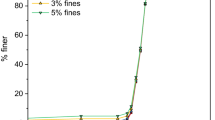

Moon SW, Vinoth G, Subramanian S, Kim J, Ku T (2020) Effect of fine particles on strength and stiffness of cement treated sand. Granul Matter 22:9

Pan Y, Liu Y, Xiao H, Lee FH, Phoon KK (2018) Effect of spatial variability on short-and long-term behaviour of axially-loaded cement-admixed marine clay column. Comp Geotech 94:150–168

Park S-S (2010) Effect of wetting on unconfined compressive strength of cemented sands. J Geotech Geoenviron Eng 136(12):1713–1720

Rios S, Da Fonseca A, Baudet BA (2014) On the shearing behaviour of an artificially cemented soil. Acta Geotech 9(2):215–226

Salgado R, Bandini P, Karim A (2000) Shear strength and stiffness of silty sand. J Geotech Geoenviron Eng 126(5):451–462

Saxena SK, Reddy KR, Avramidis AS (1988) Liquefaction resistance of artificially cemented sand. J Geotech Eng 114(12):1395–1414

Stracke F, Jung JG, Korf EP, Consoli NC (2012) The influence of moisture content on tensile and compressive strength of artificially cemented sand. Soils Rocks 35(3):303–308

Subramanian S, Moon S-W, Moon J, Ku T (2018) CSA-treated sand for geotechnical application: microstructure analysis and rapid strength development. J Mater Civ Eng 30(12):4018313

Toll DG, Ali Rahman Z (2017) Critical state shear strength of an unsaturated artificially cemented sand. Géotechnique 67(3):208–215

Towhata I (2007) Developments of soil improvement technologies for mitigation of liquefaction risk. In: Proceedings of the 4th international conference earthquake geotechnical engineering-invited lectures. Thessaloniki, Greece. Springer, Dordrecht, pp 355–383

Vinoth G, Moon S-W, Kim J, Ku T (2018a) Effect of fine particles on cement treated sand. In: Wu W, Yu H-S (eds) Proceedings of China-Europe conference on geotechnical engineering. Springer, Cham, pp 847–851

Vinoth G, Moon S-W, Moon J, Ku T (2018) Early strength development in cement-treated sand using low-carbon rapid-hardening cements. Soils Found 58(5):1200–1211

Wei X, Ku T (2019) New design chart for geotechnical ground improvement: characterizing cement-stabilized sand. Acta Geotech 15:999–1011

Wei X, Yang J (2019) Cyclic behavior and liquefaction resistance of silty sands with presence of initial static shear stress. Soil Dyn Earthq Eng 122:274–289

Wei X, Guo Y, Yang J, Guo C-B (2018) Liquefaction characteristics of four Ya-An low-plastic silty sands with presence of initial static shear stress. In: Qiu T, Tiwari B, Zhang Z (eds) Volume 1 of Proceedings of the GeoShanghai 2018 international conference on advance soil dynamics found engineering. Springer, Singapore, pp 62–69

Xiao Y, Yuan Z, Lin J, Ran J, Dai B, Chu J, Liu H (2019) Effect of particle shape of glass beads on the strength and deformation of cemented sands. Acta Geotech 14(6):2123–2131

Yang J, Gu XQ (2013) Shear stiffness of granular material at small strains: does it depend on grain size? Géotechnique 63(2):165–179

Yao K, Li N, Chen DH, Wang W (2019) Generalized hyperbolic formula capturing curing period effect on strength and stiffness of cemented clay. Constr Build Mater 199:63–71

Yasuda S, Harada K, Ishikawa K, Kanemaru Y (2012) Characteristics of liquefaction in Tokyo Bay area by the 2011 Great East Japan Earthquake. Soils Found 52(5):793–810

Zhou J-J, Gong X-N, Wang K-H, Zhang R-H (2018) Shaft capacity of the pre-bored grouted planted pile in dense sand. Acta Geotech 12(5):1227–1239

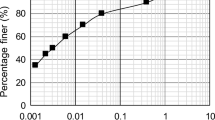

Zuo L, Baudet B (2015) Determination of the transitional fines content of sand-non plastic fines mixtures. Soils Found 55(1):213–219

Acknowledgments

This research was supported by the Singapore Ministry of Education (MOE); Award No. R-302-000-194-114.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

From Fig. 10b, it is possible to obtain the following relationship between R, t, and a.

Rearranging Eq. 6, the following equation is obtained,

Based on the geometric relationships, one may obtain the following equation.

Rearrange to obtain the following equation.

Combine Eqs. 7 and 9 to obtain the following equation.

The derivation of the radius ratio a/R has also been performed by Fernandez and Santamarina [11] for cement-stabilized clean sand. This study is further expanded from Eq. 10. If fines are considered, it is reasonable to assume the following relationship between the volumes of coating (Vcoat), cement (Vcement), fines (Vfines) and water (Vwater),

where k is a parameter to represent the effect of the amount of water on the volume of the coating, taking into account the complex physical interaction between water and cement–clay mixture; it should be a function of both cement content and fines content. Equation 11 also assumes that the cement–clay and cement–water chemical reactions do not affect the volume of the mixture during sample preparation, and the volume of air in the coating is zero. The volumetric relationship can be rewritten in terms of FC, cc, and wsoil as follows:

where Gs,fines, Gs,cement, and Gs,sand are specific gravity of fines, cement, and sand, respectively. Combine Eqs. 10 and 12 to obtain the following equation.

In Eq. 13, the contact radius increases with increasing water content if k > 0, when FC and cc are given. In addition, the cementitious bonding area also depends on the mass ratio of cement and fines to sand particles. Assuming Gs,sand = Gs,fines = Gs,cement = Gs, and k = 1, Eq. 13 can be deduced as follows:

Equation 14 indicates that the bonding area also depends on the mass ratio of cement and fines to sand particles, i.e., (FC+ cc)/(1 − FC), when the difference of the specific gravities is ignored.

Rights and permissions

About this article

Cite this article

Wei, X., Liu, H. & Ku, T. Microscale analysis to characterize effects of water content on the strength of cement-stabilized sand–clay mixtures. Acta Geotech. 15, 2905–2923 (2020). https://doi.org/10.1007/s11440-020-01018-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01018-3