Abstract

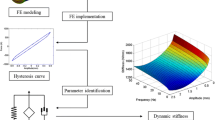

Despite being investigated for many years, the Mullins effect is considered a major obstacle in understanding the behavior of rubber, especially in antivibration design and applications. It is important that not all current models relate the Mullins effect with a physical rubber property and the response is not measured in real time. In this paper, we propose a new method for antivibration applications. The full Mullins effect in the modified hyperelastic model, with stress softening and residual strain from the virgin state, is assumed to be a combination of damage, energy dissipation, and time-dependent characteristics. The measurable property of rubber (i.e. rebound resilience) is included. An industrial product, a circular rubber mount used for rail vehicles, is utilized for the experiment and simulation verification. The real-time history of the load and deflection calculated from the model is compared to the experimental data. In addition, the load-deflection responses of five consecutive cycles are extracted from the simulated historical data. To verify the proposed approach further, an overloading procedure 20% beyond specification is performed on three consecutive cycles. The comparisons between the simulation and the test data, in both the time-domain and load-deflection form, demonstrate the accuracy and reliability of the proposed approach. As the hyperelastic models are widely used in industry, the modification on existing models can be easily achieved and applied to antivibration applications.

Similar content being viewed by others

References

Andrieux, F., Saanouni, K.: On a damaged hyperelastic medium: Mullins effect with irreversible strain. Int. J. Damage Mech. 8(1), 82–101 (1999)

Bacca, M., Creton, C., McMeeking, R.: A model for the Mullins effect in multinetwork elastomers. J. Appl. Mech. 84, 121009 (2017)

Bower, A.: Applied Mechanics of Solids. CRC Press, USA (2010)

BS ISO 4662:2017: Rubber, Vulcanized or Thermoplastic – Determination of Rebound Resilience. BSI British Standards Limited, London (2017)

Chen, Y., Kang, G., Yuan, J., et al.: Uniaxial ratchetting of filled rubber: experiments and damage-coupled hyper-viscoelastic-plastic constitutive model. J. Appl. Mech. 85, 061013 (2018)

Cheng, M., Chen, W., Song, B.: Phenomenological modelling of the stress-stretch behaviour of EPDM rubber with loading –rate and damage effects. Int. J. Damage Mech. 13, 371–381 (2004)

Dassault Systems: Abaqus User Manual. Dassault Systems, USA (2018)

Diani, J., Tallec, L.P.: A fully equilibrated microsphere model with damage for rubber like materials. J. Mech. Phys. Solids 124, 702–713 (2019)

Diani, J., Fayolle, B., Gilormini, P.: A review on the Mullins effect. Eur. Polym. J. 45(3), 601–612 (2009)

Diani, J., Merckel, Y., Brieu, M.: Modelling Mullins and cyclic stress-softening in filled Rubbers. In: Jerrams, S., Murphy, N. (eds.) Constitutive Models for Rubber VII, pp. 229–234. Taylor & Francis, London (2012)

Dorfmann, A., Ogden, R.W.: A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber. Int. J. Solids Struct. 41, 1855–1878 (2004)

Gornet, L., Marckmann, G., Desmorat, R., et al.: A new isotropic hyperelastic strain energy function in terms of invariants and its derivation into a pseudo-elastic model for Mullins effect: application to finite element analysis. In: Jerrams, S., Murphy, N. (eds.) Constitutive Models for Rubber VII, pp. 265–271. Taylor & Francis, London (2012)

Harwood, J.A.C., Mullins, L., Payne, A.R.: Stress softening in natural rubber vulcanizates. Part II. Stress softening effects in pure gum and filler loaded rubbers. Rubber Chem. Technol. 39, 814–822 (1966)

Kumar, N., Patel, B.P., Rao, V.V., et al.: Compressibility, damage and age hardening effects of solid propellants using finite strain constitutive model. J. Eng. Mater. Technol. (2018). https://doi.org/10.1115/1.4042661

Luo, R.K.: Mullins damage effect on rubber products with residual strain. Int. J. Damage Mech. 24(2), 153–167 (2015)

Luo, R.K.: Creep prediction with temperature effect and experimental verification of rubber suspension components used in rail vehicles. J. Mech. Eng. Sci. 233(11), 3950–3963 (2019)

Luo, R.K.: Complete loading-unloading-deflection prediction for antivibration system design using an energy dissipation approach. Proc. IMechE Part L, J. Mater., Des. Appl. 234(6), 859–872 (2020)

Luo, R.K., Wu, W.X.: Fatigue failure analysis of anti-vibration rubber spring. Eng. Fail. Anal. 13(1), 110–116 (2006)

Luo, R.K., Wu, X.P.: Simulation and experiment on rubber components using rebound energy approach with stress softening. J. Strain Anal. Eng. Des. 49(2), 76–85 (2014a)

Luo, R.K., Wu, W.X., Cook, P.W., Mortel, W.J.: An approach to evaluate the service life of rubber springs used in rail vehicle suspensions. J. Rail Rapid Transit 218(2), 173–177 (2004)

Luo, R.K., Peng, L.M., Wu, X.P.: Mullins effect modelling and experiment for anti-vibration systems. Polym. Test. 40, 304–312 (2014b)

Luo, R.K., Mortel, W.J., Wu, X.P.: Evaluation of stress softening on rubber suspension used in rail vehicles. J. Rail Rapid Transit 230(1), 15–23 (2016)

Lv, X., Liu, L., Liu, Y., et al.: Electromechanical modeling of softening behavior for dielectric elastomers. J. Appl. Mech. 85, 111010 (2018)

Merckel, Y., Brieu, M., Diani, J., Berghezan, D.: Effect of material and mechanical parameters on the stress-softening of carbon-black filled rubbers submitted to cyclic loadings. In: Jerrams, S., Murphy, N. (eds.) Constitutive Models for Rubber VII, pp. 253–257. Taylor & Francis, London (2012)

Merckel, Y., Brieu, M., Diani, J., et al.: Understanding and modelling the Mullins softening from a mechanical point of view. In: Gil-Negrete, Alonso (eds.) Constitutive Models for Rubber VIII, pp. 411–417. Taylor & Francis, The Netherland (2013)

Mullins, L.: Effect of stretching on the properties of rubber. J. Rubber Res. 16, 275–289 (1947)

Mullins, L.: Softening of rubber by deformation. Rubber Chem. Technol. 42, 339–362 (1969)

Nagdi, K.: Rubber as an Engineering Material: Guideline for Users. Hanser Publishers, Germany (1993)

Ogden, R.W.: Non-linear Elastic Deformations. Ellis Horwood, Chichester (1984)

Ogden, R.W., Roxburgh, D.G.: A pseudo-elastic model for the Mullins effect in filled rubber. Proc. R. Soc. Lond. A 455, 2861–2878 (1999a)

Ogden, R.W., Roxburgh, D.G.: An energy-based model of the Mullins effect. In: Dorfmann, A., Muhr, A. (eds.) Constitutive Models for Rubber, pp. 23–28. Balkema, Rotterdam (1999b)

Praffcke, J., Abraham, F.: Potentials of FEA-simulation for elastomer stress softening in engineering practice. In: Jerrams, S., Murphy, N. (eds.) Constitutive Models for Rubber VII, pp. 375–380. Taylor & Francis, London (2012)

Rickaby, S., Scott, N.: The Mullins effect. In: Jerrams, S., Murphy, N. (eds.) Constitutive Models for Rubber VII, pp. 273–276. Taylor & Francis, London (2012)

Sasso, M., Chiappini, G., Rossi, M., et al.: Structural analysis of an elastomeric bellow seal in unsteady conditions: simulations and experiments. Int. J. Mech. Mater. 13, 347–362 (2017)

Sokolov, A.K., Svistkov, A.L., Shadrin, V.V., et al.: Influence of the Mullins effect on the stress–strain state of design at the example of calculation of deformation field in tyre. Int. J. Non-Linear Mech. 104, 67–74 (2018)

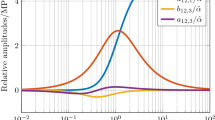

Xu, Z.D., Shen, Y.P., Zhao, H.T.: A synthetic optimization analysis method on structures with viscoelastic dampers. Soil Dyn. Earthq. Eng. 23(8), 683–689 (2003)

Xu, Z.D., Xu, C., Hu, J.: Equivalent fractional Kelvin model and experimental study on viscoelastic damper. J. Vib. Control 21(13), 2536–2552 (2013)

Xu, Z.D., ASCE, A.M., Liao, Y.X., et al.: Experimental and theoretical study of viscoelastic dampers with different matrix rubbers. J. Eng. Mech. 142(8), 04016051 (2016)

Acknowledgements

The author would like to thank Mr. John Simmonds, Mr. Jonathan Foster, and Mr. David Moore at Trelleborg AVS (U.K.) for their technical support. Theoretical discussions with colleagues in Central Southern University are also appreciated. The comments, suggested by the reviewer, have greatly enhanced the investigation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of conflicting interests

The author declares that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, R.K. Investigation on the full Mullins effect using time-dependent hyperelastic model with energy dissipation for rubber antivibration applications. Mech Time-Depend Mater 25, 581–600 (2021). https://doi.org/10.1007/s11043-020-09461-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-020-09461-1