Abstract

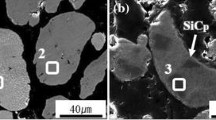

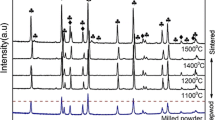

In this research V4AlC3 based composites were synthesized by reactive spark plasma sintering (RSPS) method. V2O5:Al:C starting materials with molar ratios of 1:6:1.5 and 1:7:1.5 were heat treated at 1400 °C. Final composition, microstructural, physical, mechanical and tribological properties of the prepared composites were compared. The X-ray diffraction analysis results showed that the formation of V4AlC3 as main phase alongside Al2O3 and V2AlC by-products. Increasing the Al content from 6 moles to 7 moles led to formation of VC0.845 and Al2O3 main phases as well as V4AlC3 and V2AlC minor phases in this sample due to extraction of Al from die during RSPS operation. Microstructural studies revealed that the uniform distribution of the phases with low amount of porosities. The layered microstructure of the composites confirmed the formation of MAX phases. Higher bending strength and is achieved for the synthesized composite prepared by 7 moles Al (490 ± 5 MPa) than the composite prepared with 6 moles Al (375 ± 11 MPa). The composite prepared with 7 moles Al also exhibited lower wear rate (3.7 × 10− 5 mm3/Nm) than that of prepared with 6 moles Al (2.4 × 10− 4 mm3/Nm). Microstructural studies of the worn surfaces indicated that tribo oxidation is dominant mechanism for both fabricated composites.

Graphic Abstract

Similar content being viewed by others

References

M. Sokol, V. Natu, S. Kota, M.W. Barsoum, Trends Chem. 1, 210–223 (2019)

Y. Bai, N. Srikanth, C.K. Chua, K. Zhou, Crit. Rev. Solid State Mater. Sci. 44, 56–107 (2019)

H. Zhang, T. Hu, X. Wang, Y. Zhou, J. Mater. Sci. Technol. 38, 205–220 (2020)

H. Zhang, T. Hu, X. Wang, Z. Li, M. Hu, E. Wu, Y. Zhou, Sci. Rep. 5, 14192 (2015)

N. Ghosh, S. Harimkar, Advances in Science and Technology of Mn + 1AXn Phases (Elsevier, New York, 2012), pp. 47–80

W. Jeitschko, H.t. Nowotny, F. Benesovsky, Journal of the Less Common Metals 7, 133–138 (1964)

V.H. Nowotny, Prog. Solid State Chem. 5, 27–70 (1971)

W. Jeitschko, H. Nowotny, Monat. Chem. Chem. Mon. 98, 329–337 (1967)

M.W. Barsoum, L. Farber, I. Levin, A. Procopio, T. El-Raghy, A. Berner, J. Am. Ceram. Soc. 82, 2545–2547 (1999)

J. Schuster, H. Nowotny, C. Vaccaro, J. Solid State Chem. 32, 213–219 (1980)

J. Etzkorn, M. Ade, H. Hillebrecht, Inorg. Chem. 46, 7646–7653 (2007)

C. Hu, J. Zhang, J. Wang, F. Li, J. Wang, Y. Zhou, J. Am. Ceram. Soc. 91, 636–639 (2008)

B. Hallstedt, Calphad 41, 156–159 (2013)

S. Gupta, M. Barsoum, J. Electrochem. Soc. 151, D24 (2004)

C.M. Hamm, T. Schäfer, H. Zhang, C.S. Birkel, Z. Anorg. Allg. Chem. 642, 1397–1401 (2016)

M. Hossein-Zadeh, O. Mirzaee, H. Mohammadian-Semnani, Ceram. Int. 45, 7446–7457 (2019)

A. Fazili, M.R. Derakhshandeh, S. Nejadshamsi, L. Nikzad, M. Razavi, E. Ghasali, J. Alloys Compd. 823, 153857 (2020)

Y. Orooji, E. Ghasali, M. Moradi, M.R. Derakhshandeh, M. Alizadeh, M.S. Asl, T. Ebadzadeh, Ceram. Int. 45, 16288–16296 (2019)

Y. Orooji, A.a. Alizadeh, E. Ghasali, M.R. Derakhshandeh, M. Alizadeh, M.S. Asl, T. Ebadzadeh, Ceram. Int. 45, 20844–20854 (2019)

Y. Orooji, M.R. Derakhshandeh, E. Ghasali, M. Alizadeh, M.S. Asl, T. Ebadzadeh, Ceram. Int. 45, 16015–16021 (2019)

K. Shirvanimoghaddam, E. Ghasali, A. Pakseresht, S. Derakhshandeh, M. Alizadeh, T. Ebadzadeh, M. Naebe, J. Alloys Compd. 775, 601–616 (2019)

S. Derakhshandeh, M.S. Gohari, E.K. Saeidabadi, A. Jam, A. Fazili, M. Alizadeh, E. Ghasali, A. Pakseresht, T. Ebadzadeh, Ceram. Int. 44, 13176–13181 (2018)

M. Derakhshandeh, M.S. Naeini, E. Ghasali, A. Jam, A. Fazili, M. Alizadeh, A. Kazemzadeh, T. Ebadzadeh, Ceram. Int. 45, 6477–6483 (2019)

C. Hu, L. He, M. Liu, X. Wang, J. Wang, M. Li, Y. Bao, Y. Zhou, J. Am. Ceram. Soc. 91, 4029–4035 (2008)

G.S. Park, G.G. Kim, S.J. Kim, J. Nucl. Mater. 352, 80–84 (2006)

S. Gupta, S. Amini, D. Filimonov, T. Palanisamy, T. El-Raghy, M. Barsoum, J. Am. Ceram. Soc. 90, 3566–3571 (2007)

S. Gupta, M. Barsoum, Wear 271, 1878–1894 (2011)

S. Gupta, D. Filimonov, V. Zaitsev, T. Palanisamy, M.W. Barsoum, Wear 264, 270–278 (2008)

C. Magnus, J. Sharp, W.M. Rainforth, Tribol. Trans. 63, 38–51 (2020)

L. Tan, C. Guan, Y. Tian, P. Dang, S. Wang, J. Li, W. Li, Z. Zhao, J. Ceram. Soc. Jpn. 127, 754–760 (2019)

A. Loganathan, A. Sahu, C. Rudolf, C. Zhang, S. Rengifo, T. Laha, B. Boesl, A. Agarwal, Surf. Coat.Technol. 334, 384–393 (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sadeghi, L., Razavi, M., Kalantarian, M.M. et al. Synthesize of V4AlC3 Based MAX Phase Composites by Reactive Spark Plasma Sintering of V2O5:Al:C. Met. Mater. Int. 27, 5247–5257 (2021). https://doi.org/10.1007/s12540-020-00852-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00852-0