Article contents

Effect of lithium carbonate on the sintering, microstructure, and functional properties of sol–gel-derived Ba0.85Ca0.15Zr0.1Ti0.9O3 piezoceramics

Published online by Cambridge University Press: 28 August 2020

Abstract

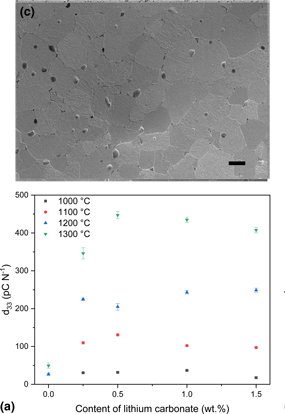

Piezoelectric Ba0.85Ca0.15Zr0.1Ti0.9O3 (BCZT) has been found to be a competitive lead-free piezoceramic candidate and was prepared by a sol–gel technique due to its small particle size and homogeneous particle size distribution, but the sintering temperature is still quite high in the previous reports. In the present paper, lithium carbonate (Li2CO3) was used as a sintering aid and dopant for the sol–gel-derived piezoceramic powder, to facilitate the sintering process and adjust the densification, the microstructures and functional properties. With the addition of 0.5 wt% Li2CO3 sintered at 1300 °C, a high relative density 96% with piezoelectric coefficient d33 ~447 pC/N, planar coupling coefficient kp ~0.51, and Curie point TC ~98.7 °C was obtained. The way to properly define the critical changing points on temperature-dependent dielectric curves were further discussed. By altering sintering temperature and the amount of dopant, the mutual influence between the microstructures and the functional properties was explained, to further guide shaping BCZT in more complexed connectivities.

Keywords

- Type

- Invited Paper

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 3

- Cited by