Abstract

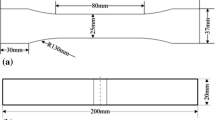

Friction stir spot welding was successfully applied to the 1.2-mm-thick DH590 dual-phase steel plates by using a polycrystalline cubic boron nitride rotating tool. During welding, the rotation speed ranged from 600 to 1000 r/min and the penetration depth ranged from 0.1 to 0.3 mm. In the spot joints, the size of the stir zone increased with the increase in rotation speed as well as the penetration depth of the tool. Comparing with the banded ferrite and martensite structure of the base metal, a mixed microstructure of ferrite and tempered martensite, refined bainite structure and coarse martensite structure were found in the heat-affected zone, thermomechanically affected zone and stir zone of the joints, respectively. Two kinds of interfacial shapes were formed between the upper and lower steel plates, and the formation of the bonded interface was dominated mainly by the penetration depth of the rotating tool rather than the rotation speed. It was revealed that the joints with straight interfaces showed higher shear tensile loads comparing with those with hook-like interfaces. Shear tensile tests showed that the maximum shear tensile load reached about 15.56 kN when the rotation speed and penetration depth were set as 800 r/min and 0.3 mm, respectively. The specimen was fractured through plug failure mode with a total elongation of about 5.6 mm.

Similar content being viewed by others

References

M.P. Miles, C.S. Ridges, Y. Hovanski, J. Peterson, M.L. Santella, R. Steel, Sci. Technol. Weld. Joining 16 (2011) 642–647.

X. Sun, F. Meng, J. Liu, J. McKechnie, J. Yang, J. Clean. Product. 220 (2019) 1–8.

H.W. Zhao, R.B. Zhang, Z.Y. Bin, in: 2018 International Conference on Mechanical, Electronic, Control and Automation Engineering (MECAE 2018), Atlantis Press, Qingdao, China, 2018, pp. 59–62.

G.K. Ahiale, Y.J. Oh, W.D. Choi, K.B. Lee, J.G. Jung, S.W. Nam, Met. Mater. Int. 19 (2013) 933–939.

C.J. Xie, S.L. Yang, H.B. Liu, Q. Zhang, Y.M. Cao, Y. Wang, J. Mater. Eng. Perform. 26 (2017) 3794–3801.

T.K. Pal, K. Bhowmick, J. Mater. Eng. Perform. 21 (2012) 280–285.

T. Hartman, M.P. Miles, S.T. Hong, R. Steel, S. Kelly, Wear 328–329 (2015) 531–536.

M.I. Khan, M.L. Kuntz, P. Su, A. Gerlich, T. North, Y. Zhou, Sci. Technol. Weld. Joining 12 (2007) 175–182.

Z. Shen, W.Y. Li, Y. Ding, W. Hou, X.C. Liu, W. Guo, H.Y. Chen, X. Liu, J. Yang, A.P. Gerlich, J. Manuf. Proc. 49 (2020) 260–270.

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, C.J. Dawes, Friction stir butt welding, PCT/GB92/02203, Japan, 1991.

G.P. Dinda, A. Ramakrishnan, Int. J. Adv. Manuf. Technol. 103 (2019) 4763–4769.

E. Biro, J.R. McDermid, J.D. Embury, Y. Zhou, Metall. Mater. Trans. A 41 (2010) 2348–2356.

Y.F. Sun, H. Fujii, N. Takaki, Y. Okitsu, Mater. Des. 37 (2012) 384–392.

F.C. Liu, Y. Hovanski, M.P. Miles, C.D. Sorensen, T.W. Nelson, J. Mater. Sci. Technol. 34 (2018) 39–57.

Y.F. Sun, J.M. Shen, Y. Morisada, H. Fujii, Mater. Des. 54 (2014) 450–457.

L.Cui, C. Zhang, Y.C. Liu, X.G. Liu, D.P. Wang, H.J. Li, J. Iron Steel Res. Int. 25 (2018) 477–486.

T. Liyanage, J. Kilbourne, A.P. Gerlich, T.H. North, Sci. Technol. Weld. Joining 14 (2009) 500–508.

T. Weinberger, N. Enzinger, H. Cerjak, Sci. Technol. Weld. Joining 14 (2009) 210–215.

R. Sarkar, T.K. Pal, M. Shome, Sci. Technol. Weld. Joining 19 (2014) 436–442.

H. Das, K.J. Lee, S.T. Hong, J. Mater. Eng. Perform. 26 (2017) 3607–3613.

R. Ohashi, M. Fujimoto, S. Mironov, Y.S. Sato, H. Kokawa, Sci. Technol. Weld. Joining 14 (2009) 221–227.

R. Ohashi, Weld. World 55 (2011) 2–11.

R. Ohashi, M. Fujimoto, S. Mironov, Y.S. Sato, H. Kokawa, Weld. World 53 (2009) 23–27.

H. Lee, C. Kim, J.H. Song, Materials 8 (2015) 8424–8436.

E. Aldanondo, A. Taboada, E. Arruti, P. Alvarez, A. Echeverria, in: Proceedings of the 1st International Joint Symposium on Joining and Welding, Woodhead Publishing, Osaka, Japan, 2013, pp. 179–182.

Z.W. Wang, G.N. Ma, B.H. Yu, P. Xue, G.M. Xie, H. Zhang, D.R. Ni, B.L. Xiao, Z.Y. Ma, Sci. Technol. Weld. Joining 25 (2020) 336–344.

G.Q. Wang, Y.H. Zhao, Y.F. Hao, J. Mater. Sci. Technol. 34 (2018) 73–91.

A.K. Lakshminarayanan, V. Balasubramanian, M. Salahuddin, J. Iron Steel Res. Int. 17 (2010) No. 10, 68–74.

M. Mahmoudiniya, A.H. Kokabi, S. Kheirandish, L. Kestens, Mater. Sci. Eng. A 737 (2018) 213–222.

F. Fang, Y.Y. Yin, H. Wang, C.J. Lin, Adv. Mater. Res. 548 (2012) 301–304.

H. Das, M. Mondal, S.T. Hong, Y. Lim, K.J. Lee, Mater. Charact. 139 (2018) 428–436.

A. Barabi, A. Zarei-Hanzaki, H. Abedi, A. Anoushe, J.H. Cho, Steel Res. Int. 89 (2018) 1800245.

G. Pérez-Medina, H. Lopez, A. Miranda-Pérez, E. Hurtado-Delgado, J. Iron Steel Res. Int. 27 (2020) 188–196.

C.X. Liu, L. Shi, Y.C. Liu, C. Li, H.J. Li, Q.Y. Guo, J. Mater. Sci. 51 (2016) 3555–3563.

R.A. Ricks, P.R. Howell, G.S. Barritte, J. Mater. Sci. 17 (1982) 732–740.

R. Ghomashchi, W. Costin, R. Kurji, Mater. Charact. 107 (2015) 317–326.

A.K. Lakshminarayanan, V.E. Annamalai, K. Elangovan, J. Mater. Res. Technol. 4 (2015) 262–272.

M.M.Z. Ahmed, E. Ahmed, A.S. Hamada, S.A. Khodir, M.M.E.S. Seleman, B.P. Wynne, Mater. Des. 91 (2016) 378–387.

O. Abedini, E. Ranjbarnodeh, P. Marashi, Mater. Technol. 51 (2017) 687–694.

M.A.M. Hossain, M.T. Hasan, S.T. Hong, M. Miles, H.H. Cho, H.N. Han, Met. Mater. Int. 19 (2013) 1243–1250.

B. Wang, L. Hua, X.K. Wang, J.J. Li, Int. J. Adv. Manuf. Technol. 86 (2016) 2927–2935.

S. Miller, E. Pfeif, A. Kazakov, E. Baumann, M. Dowell, in: Proc. SPIE 9741, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications V, International Society for Optics and Photonics, Washington, USA, 2016, pp. 97410I.

N. Saunders, M. Miles, T. Hartman, Y. Hovanski, S.T. Hong, R. Steel, Int. J. Precis. Eng. Manuf. 15 (2014) 841–848.

M. Santella, Y. Hovanski, A. Frederick, G. Grant, M. Dahl, Sci. Technol. Weld. Joining 15 (2010) 271–278.

G.M. Xie, H.B. Cui, Z.A. Luo, W. Yu, J. Ma, G.D. Wang, J. Mater. Sci. Technol. 32 (2016) 326–332.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhao, Yp., Chen, Lf., Zhu, Sj. et al. Clarifying effect of welding conditions on microstructure and mechanical properties of friction stir spot-welded DH590 automotive high-strength steel plates. J. Iron Steel Res. Int. 28, 232–243 (2021). https://doi.org/10.1007/s42243-020-00478-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00478-x