Abstract

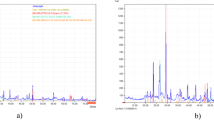

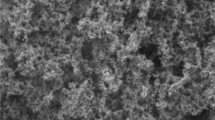

Alkali Pozzolan cement (APC) comprises a high volume of fly ash, lime, ordinary Portland cement (OPC), and a dry Na2SO4 activator. APC can be stored in dry form and only requires water to create a cementitious binder. Mechanical and microstructural properties of APC were investigated to determine the compressive strength and hydration products of different APC pastes. Air-cured APC pastes (w/b = 0.3) were found to gain 65–77% of the strength of similar OPC pastes at 28 days, while being 75% greater than that of corresponding high-volume fly ash ones. Microstructural properties studied using X-ray diffraction, scanning electron microscopy, energy-dispersive X-ray spectroscopy, and thermal analysis were able to explain the observed mechanical properties. The attacking of the smooth fly ash spheres (observed via SEM) by Ca(OH)2, evidenced by a reduction in the latter (observed through thermogravimetry) over a period of 112 days, could be linked to the strength gain of APC over that period. This strength gain could also be associated with the formation of ‘broad humps’, at the relevant 2θ values (around 29° and 32°) in XRD curves, which became more pronounced with time. Strength could also be correlated to the percentage of hydrate bound water, with the differing amounts of lime consumption by fly ash partly responsible for scatter.

Similar content being viewed by others

References

Kulasuriya C, Vimonsatit V, Dias WPS, De Silva P (2014) Design and development of alkali pozzolan cement (APC). Constr Build Mater 68:426–433

Dias WPS, Khoury G, Sullivan P (1990) Mechanical properties of hardened cement paste exposed to temperatures up to 700 C (1292 F). ACI Mater J 87(2):160–166

Feldman RF, Carette GG, Malhotra VM (1990) Studies on mechanics of development of physical and mechanical properties of high-volume fly ash-cement pastes. Cement Concr Compos 12(4):245–251

De Silva P, Glasser F (1992) Pozzolanic activation of metakaolin. Adv Cem Res 4(16):167–178

Shi C, Day RL (1993) Acceleration of strength gain of lime-pozzolan cements by thermal activation. Cem Concr Res 23(4):824–832

De Silva P, Sagoe-Crenstil K (2008) Medium-term phase stability of Na2O–Al2O3–SiO2–H2O geopolymer systems. Cem Concr Res 38(6):870–876

Kong DLY, Sanjayan JG (2010) Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem Concr Res 40(2):334–339

Garcia-Lodeiro I, Fernandez-Jimenez A, Palomo A (2013) Hydration kinetics in hybrid binders: early reaction stages. Cem Concr Compos 39:82–92

Gani MSJ (1997) Cement and concrete. Chapman & Hall, London

Neville AM, Brooks JJ (1987) Concrete technology. Longman Scientific & Technical, Harlow

Newman J, Choo BS (2003) Advanced concrete technology 3: processes. Elsevier, Burlington

Soroka I (1980) Portland cement paste and concrete. Chemical Publishing, New York

Malhotra VM, Mehta PK (1996) Pozzolanic and cementitious materials. Taylor & Francies, London

Helmuth R (1987) Fly ash in cement and concrete. Portland Cement Association, Illinois

Hong S-Y, Glasser FP (2002) Alkali sorption by C-S-H and C-A-S-H gels: part II. Role of alumina. Cem Concr Res 32(7):1101–1111

De Silva P (1993) Glasser FP, phase relations in the system CaO–Al2O3–SiO2–H2O relevant to metakaolin—calcium hydroxide hydration. Cem Concr Res 23(3):627–639

Garcia-Lodeiro I, Donatello S, Fernandez-Jimenez A, Palomo A (2016) Hydration of hybrid alkaline cement containing a large proportion of fly ash: a descriptive model. Materials 9(7):605

Krivenko P (2017) Why alkaline activation—60 years of the theory and practice of alkali-activated materials. J Ceram Sci Technol 08(3):323–334

Velandia DF, Lynsdale CJ, Provis JL, Ramirez F, Gomez AC (2016) Evaluation of activated high volume fly ash systems using Na2SO4, lime and quicklime in mortars with high loss on ignition fly ashes. Constr Build Mater 128:248–255

Velandia DF, Lynsdale CJ, Provis JL, Ramirez F (2018) Effect of mix design inputs, curing and compressive strength on the durability of Na2SO4-activated high volume fly ash concretes. Cem Concr Compos 91:11–20

Luxan M, De Rojas MS, Frias M (1989) Investigations on the fly ash-calcium hydroxide reactions. Cem Concr Res 19(1):69–80

Shi C, Jiménez AF, Palomo A (2011) New cements for the 21st century: the pursuit of an alternative to Portland cement. Cem Concr Res 41(7):750–763

Aimin X, Sarkar SL (1991) Microstructural study of gypsum activated fly ash hydration in cement paste. Cem Concr Res 21:1137–1147

Lee C, Lee H, Lee K (2003) Strength and microstructural characteristics of chemically activated fly ash–cement systems. Cem Concr Res 33(3):425–431

Jumate E, Manea DL (2011) X-ray diffraction study of hydration processes in the Portland cement. J Appl Eng Sci 1(14):79–86

Papadakis VG (1999) Effect of fly ash on Portland cement systems: Part I. Low-calcium fly ash. Cem Concr Res 29(11):1727–1736

Goñi S, Puertas F, Hernández MS, Palacios M, Guerrero A, Dolado JS, Zanga B, Baroni F (2010) Quantitative study of hydration of C3S and C2S by thermal analysis. J Therm Anal Calorim 102:965–973

Li S, Roy DM, Kumar A (1985) Quantatative determination of pozzolanas in hydrated systems of cement or Ca(OH)2 with fly ash or silica fume. Cem Concr Res 15:1079–1086

Li D, Chen Y, Shen J, Su J, Wu X (2000) The influence of alkalinity on activation and microstructure of fly ash. Cem Concr Res 30(6):881–886

Ribeiro DV, Yuan SY, Morelli MR (2012) Effect of chemically treated leather shaving addition on characteristics and microstructure of OPC mortars. Mater Res 15(1):136–143

Batic OR, Milanesi CA, Maiza PJ, Marfil SA (2000) Secondary ettringite formation in concrete subjected to different curing conditions. Cem Concr Res 30(9):1407–1412

Chakchouk A, Samet B, Bouaziz S (2012) Difference in pozzolanic behaviour of Tunisian clays with lime and cement. Adv Cem Res 24(1):11–22

El-Jazairi B, Illston J (1977) A simultaneous semi-isothermal method of thermogravimetry and derivative thermogravimetry, and its application to cement pastes. Cem Concr Res 7(3):247–257

Vedalakshmi R, Raj AS, Srinivasan S, Babu KG (2003) Quantification of hydrated cement products of blended cements in low and medium strength concrete using TG and DTA technique. Thermochim Acta 407(1–2):49–60

Ukrainczyk N, Ukrainczyk M, Šipušić J, Matusinović T (2006) XRD and TGA investigation of hardened cement paste degradation. In: Proceedings of the 11th International Conference on Materials, Processes, Friction and Wear (MATRIB'O6), pp 243–249

Almeida AEFS, Sichieri EP (2006) Thermogravimetric analyses and mineralogical study of polymer modified mortar with silica fume. Mater Res 9(3):321–326

Alarcon-Ruiz L, Platret G, Massieu E, Ehrlacher A (2005) The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem Concr Res 35(3):609–613

Fordham CJ, Smalley IJ (1985) A simple thermogravimetric study of hydrated cement. Cem Concr Res 15(1):141–144

Chaipanich A, Nochaiya T (2010) Thermal analysis and microstructure of Portland cement-fly ash-silica fume pastes. J Therm Anal Calorim 99(2):487–493

Kulasuriya C, Dias WPS, Vimonsatit V (2019) Durability properties of alkali pozzolan cement (APC). J Natl Sci Found Sri Lanka 47(1):121–131

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One part activated materials: a review. Cem Concr Res 103:21–34

Qian J, Shi C, Wang Z (2001) Activation of blended cements containing fly ash. Cem Concr Res 31(8):1121–1127

Dias WPS, Nanayakkara SMA, Ekneligoda TC (2003) Performance of concrete mixes with OPC-PFA blends. Mag Concr Res 55(2):161–170

Kumar R, Kumar S, Mehrotra SP (2007) Towards sustainable solutions for fly ash through mechanical activation. Resour Conserv Recycl 52(2):157–179

Singh M, Garg M (1999) Cementitious binder from fly ash and other industrial wastes. Cem Concr Res 29(3):309–314

Dakhane A, Tweedly S, Kailas S, Marzke R, Neithalath N (2018) Mechanical and microstructural characterization of alkali sulfate activated high volume fly ash binders. Mater Des 122:236–246

Brown P, Jones T, BéruBé K (2011) The internal microstructure and fibrous mineralogy of fly ash from coal-burning power stations. Environ Pollut 159(12):3324–3333

Shi C (1992) Activation of natural pozzolans, fly ashes and blast furnace slag, Ph.D. thesis submitted to University of Calgary, Calgary

Marsh BK, Day RL (1988) Pozzolanic and cementitious reactions of fly ash in blended cement pastes. Cem Concr Res 18(2):301–310

Chang C-F, Chen J-W (2006) The experimental investigation of concrete carbonation depth. Cem Concr Res 36(9):1760–1767

Kulasuriya C (2015) Alkali Pozzolan cement for integral sustainability, Ph.D. thesis submitted to Curtin University, Perth

Pane I, Hansen W (2005) Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem Concr Res 35(6):1155–1164

Knapen E, Cizer O, Van Balen K, Van Gemert D (2009) Effect of free water removal from early-age hydrated cement pastes on thermal analysis. Constr Build Mater 23(11):3431–3438

Sha W, O'Neill EA, Guo Z (1999) Differential scanning calorimetry study of ordinary Portland cement. Cem Concr Res 29(9):1487–1489

Bradbury C, Callaway P, Double D (1976) The conversion of high alumina cement/concrete. Mater Sci Eng 23(1):43–53

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kulasuriya, C., Dias, W.P.S., Vimonsatit, V. et al. Mechanical and Microstructural Properties of Alkali Pozzolan Cement (APC). Int J Civ Eng 18, 1281–1292 (2020). https://doi.org/10.1007/s40999-020-00534-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-020-00534-3