Abstract

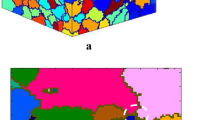

The motion of free grains has a significant influence on the solidification structure, solute distribution, and defects of large casts. However, few studies have modeled the solidification structure of large casts considering grain motion. In this paper, taking into account the motion of free grains, a multiscale cellular automaton model is proposed to predict the solidification structure of continuously cast billets. The model is validated with experimental measurements. Then, the proposed model is adopted to investigate the solidification structure evolution of a wire steel 82b cast by a bow-type continuous caster with a billet section size of 160 mm × 160 mm. The results show that the growth of columnar grains in inner arc of billet strand is promoted by the sedimentation of free equiaxed grains. But the columnar grains in outer arc of strand are blocked once free grains nucleate before them. Thus, asymmetric morphology of solidification structure in the 82b billet with casting speed of 1.8 m/min is quantitatively determined and the length of the columnar grains in the inner arc and the outer arc of strand is 57.0 mm and 31.0 mm, respectively. Moreover, compared with the difference of cooling intensity between inner arc and outer arc in secondary cooling zone, the motion of free grains dominates the asymmetric morphology in the 82b billet.

Similar content being viewed by others

References

M. Stefan-Kharicha, A. Kharicha, M. Wu, and A. Ludwig: Metall. Mater. Trans. A, 2018, vol. 49, pp. 1708-24.

A. Ludwig, M. Wu, and A. Kharicha: Metall. Mater. Trans. A, 2015, vol. 46, pp. 4854-67.

G. Lesoult: Mater. Sci. Eng. A, 2005, vol. 413-414, pp. 19-29.

D.G. Eskin, J. Zuidema, V.I. Savran, and L. Katgerman: Mater. Sci. Eng. A, 2004, vol. 384, pp. 232-44.

B. Appolaire, V. Albert, H. Combeau, and G. Lesoult: Acta Mater., 1998, vol. 46, pp. 5851-62.

B. Appolaire, V. Albert, H. Combeau, and G. Lesoult: ISIJ Int., 1999, vol. 39, pp. 263-70.

H. Esaka, T. Wakabayashi, K. Shinozuka, and M. Tamura: ISIJ Int., 2003, vol. 43, pp. 1415-20.

R.H. Mathiesen, L. Arnberg, P. Bleuet, and A. Somogyi: Metall. Mater. Trans. A, 2006, vol. 37, pp. 2515-24.

D. Ruvalcaba, R. H. Mathiesen, D. G. Eskin, L. Arnberg, and L. Katgerman: Acta Mater., 2007, vol. 55, pp. 4287-92.

L. Abou-Khalil, G. Salloum-Abou-Jaoude, G. Reinhart, C. Pickmann, G. Zimmermann, and H. Nguyen-Thi: Acta Mater., 2016, vol. 110, pp. 44-52.

C.Y. Wang and C. Beckermann: Metall. Mater. Trans. A, 1996, vol. 27, pp. 2754-64.

C. Beckermann: JOM, 1997, vol. 49, pp. 13-7.

M. Wu and A. Ludwig: Acta Mater., 2009, vol. 57, pp. 5621-31.

M. Wu, A. Ludwig, and A. Kharicha: Appl. Math. Model., 2017, vol. 41, pp. 102-20.

J. Li, M. Wu, A. Ludwig, and A. Kharicha: Int. J. Heat Mass Tran., 2014, vol. 72, pp. 668-79.

H. Ge, F. Ren, J. Li, X. Han, M. Xia, and J. Li: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1139-50.

D. Jiang and M. Zhu: Metall. Mater. Trans. B, 2017, vol. 48, pp. 444-55.

D. Jiang, W. Wang, S. Luo, C. Ji, and M. Zhu: Metall. Mater. Trans. B, 2017, vol. 48, pp. 3120-31.

R. Rojas, T. Takaki, and M. Ohno: J. Comput. Phys., 2015, vol. 298, pp. 29-40.

T. Takaki, R. Sato, R. Rojas, M. Ohno, and Y. Shibuta: Comput. Mater. Sci., 2018, vol. 147, pp. 124-31.

S. Luo, P. Wang, W. Wang, and M. Zhu: Metall. Mater. Trans. B (2020). https://doi.org/10.1007/s11663-020-01925-6.

W. Wang, C. Ji, S. Luo, and M. Zhu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 200-12.

S. Luo, M. Zhu, and S. Louhenkilpi: ISIJ Int., 2012, vol. 52, pp. 823-30.

M. Rappaz and C.A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345-60.

L. Liu, S. Pian, Z. Zhang, Y. Bao, R. Li, and H. Chen: Comput. Mater. Sci., 2018, vol. 146, pp. 9-17.

T. Takaki, T. Shimokawabe, M. Ohno, A. Yamanaka, and T. Aoki: J. Cryst. Growth, 2013, vol. 382, pp. 21-5.

T. Takaki, R. Rojas, M. Ohno, T. Shimokawabe, and T. Aoki: IOP Conf. Ser. Mater. Sci. Eng., 2015, vol. 84, p. 12066.

Z.F. Zhang, J.M. Kim, and C.P. Hong: ISIJ Int., 2005, vol. 45, pp. 183-91.

C.A. Gandin and M. Rappaz: Acta Metall. Mater., 1994, vol. 42, pp. 2233-46.

G. Guillemot, C.A. Gandin, and H. Combeau: ISIJ Int., 2006, vol. 46, pp. 880-95.

S. Chen, G. Guillemot, and C.A. Gandin: Acta Mater., 2016, vol. 115, pp. 448-67.

C.A. Gandin and M. Rappaz: Acta Mater., 1997, vol. 45, pp. 2187-95.

G. Guillemot, C.A. Gandin, and M. Bellet: J. Cryst. Growth, 2007, vol. 303, pp. 58-68.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57-63.

C.A. Gandin, G. Guillemot, B. Appolaire, and N.T. Niane: Mater. Sci. Eng. A, 2003, vol. 342, pp. 44-50.

J.S. Langer and J. Müller-Krumbhaar: J. Cryst. Growth, 1977, vol. 42, pp. 11-4.

A. Haider and O. Levenspiel: Powder Technol., 1989, vol. 58, pp. 63-70.

S. Ahuja: Ph.D. dissertation, Iowa University, Iowa City, Iowa, USA, 1992.

W. Wang, S. Luo, and M. Zhu: Comput. Mater. Sci., 2014, vol. 95, pp. 136-48.

D. Jiang and M. Zhu: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3446-58.

J.A. Spittle: Int. Mater. Rev., 2006, vol. 51, pp. 247-69.

K. Schwerdtfeger: The Making, Shaping and Treating of Steel: Casting Volume-Chapter 4, 11th ed., AISE Steel Foundation, Pittsburgh, 2003, pp. 18-28.

Acknowledgments

The authors gratefully acknowledge the financial support of National Key Research and Development Plan (Nos. 2017YFB0304100, 2016YFB0300105), National Natural Science of China (Nos. 51674072, 51704151, 51804067), and Fundamental Research Funds for the Central Universities (Nos. N182504014, N170708020, N172503013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 21, 2020.

Rights and permissions

About this article

Cite this article

Wang, Z., Luo, S., Wang, W. et al. Numerical Simulation of Solidification Structure of Continuously Cast Billet with Grain Motion. Metall Mater Trans B 51, 2882–2894 (2020). https://doi.org/10.1007/s11663-020-01953-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01953-2