Abstract

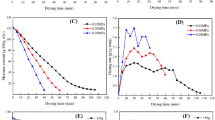

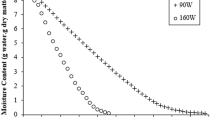

An experimental study combined with a mathematical modeling of vacuum drying of cocoa beans was carried out to enhance the drying kinetics without compromising the quality of dried products. Experiments were conducted to compare the effects of variation of temperature and pressure on the drying process. The temperature was varied between 40 and 60 °C, while the pressure between 735 and 245 mmHg. The experimental study investigated and analyzed the effects of various process parameters on drying kinetics and quality (in terms of color and pH value). Results demonstrated that the cocoa beans dried at 50 °C temperature and 735 mmHg pressure had the highest drying kinetics, lowest acidity, and best color among all the temperature and pressure values. Compared to convective drying conducted at 60 °C temperature and atmospheric pressure (760 mmHg), vacuum oven drying consistently showed better drying performance with a higher quality of dried products. Modeling for vacuum drying kinetics of cocoa beans was performed with semi-theoretical drying kinetic and fuzzy models to verify the experimental results. The graphical representations of the results demonstrated a good fit between the fuzzy model and the experimental data compared with semi-theoretical drying kinetic models. Finally, a suitable model was proposed for optimum drying conditions compared with the fuzzy and drying kinetic models that could play an important role in designing future advanced dryers.

Similar content being viewed by others

Abbreviations

- Deff:

-

Effective moisture diffusivity, m2/s

- g:

-

Constant in the two term and Verma et al. models, s−1

- g:

-

Constant in the C.L. Hii model, s−1

- k:

-

Constant in the Newton, Henderson and Pabis, logarithmic, two term, and Verma et al. models, s−1

- k:

-

Constant in the page and C.L. Hii models, s−n

- K:

-

Thermal diffusivity, m2/s

- L, a, b:

-

Reference color (lightness, redness and yellowness, respectively),

- L*, a*, b*:

-

Target color (lightness, redness and yellowness, respectively),

- mt:

-

Mass of sample at time t, g

- mds:

-

Mass of dry solid, g

- Me:

-

Equilibrium moisture content (dry basis), kg/kg

- M0:

-

Initial moisture content (dry basis), kg/kg

- Mt:

-

Moisture content at time t (dry basis), kg/kg

- MR:

-

Moisture ratio,

- pH:

-

Acidity/basicity,

- P:

-

Pressure, mm Hg

- R2 :

-

Coefficient of determination, −

- T:

-

Temperature, °C

- ΔE:

-

Change of color,

- COG:

-

Center of gravity

- FL:

-

Fuzzy logic

- MF:

-

Membership function

- MSE:

-

Mean square error

- RMSE:

-

Root mean square error

- SC:

-

Subtractive clustering

- TSK:

-

Takagi-Sugeno-Kang

References

Aamilla G, Cervantes S, Barel MA, Berthmieu G, Rodriuges-Jimens GC, Garcia-Alvarado MA (2007) Moisture acidity and temperature evolution during cacao drying. J Food Eng 79:1159–1165

Akmel DC, Assidjo NE, Kouamé P, Yao KB (2019) Modelling of sun drying kinetics of thin layer cocoa (Theobroma cacao) beans. J Appl Sci Res 5(9):1110–1116

Camu N, Winter DW, Addo SK, Takrama JS, Bernart H, Vuyst LE (2008) Fermentation of cocoa beans: influence of microbial activities and polyphenol concentrations on the flavor of chocolate. J Sci Food Agricult 88:2288–2297

Chandra PK, Singh RP (1995) Applied numerical methods for food and agricultural engineers. CRC Press, Boca Raton, pp 163–167

Chen Z, Lamb FM (2004) A vacuum drying system for green hardwood parts. Dry Technol 22:577–595

Devahastin S, Mujumdar AS (2008) Fundamental principles of drying. In: Mujumdar A.S. (ed) Guide to industrial drying. Colour Publications Pvt. Limited, India, p 1–19

Guehi TS, Zahouli IB, Ban-Koffi L, Fae MA, Nemlin JG (2010) Performance of different drying methods and their effects on the chemical quality attributes of raw cocoa material. Int J Food Sci Technol 45:1564–1571

Henderson SM, Pabis S (1969) Grain drying theory. I. Temperature effect on drying coefficient. J Agric Eng Res 6:169–174

Hii CL, Law CL, Cloke M (2009) Modelling using a new thin layer drying model and product quality of cocoa. J Food Eng 93:191–198

Hii CL, Law CL, Cloke M, Suzannah S (2009) Thin layer drying kinetics of cocoa and dried product quality. Biosyst Eng 102:153–161

Hii CL, Law CL, Cloke M (2018) Modelling of thin layer drying kinetics of cocoa beans during artificial and natural drying. J Eng Sci Technol 3(1):1–10

Hoque ME, Gee LP (2013) Biodiesel from plant resources – sustainable solution to ever increasing fuel oil demands. J Sustain Bioenergy Syst 3:163–170

Kanagaratnam S, Hoque SE, Sahri MM, Spowage A (2013) Investigating the effect of deforming temperature on the oil-binding capacity of palm oil based shortening. J Food Eng 118(1):90–99

Kuitche A, Edoun M, Takamte G (2007) Influence of pre-treatment on drying on the drying kinetic of a local Okro (Hibiscus ersculentus) variety. World J Dairy Food Sci 2(2):83–88

Kyi TM, Daud WRW, Mohammad AB, Samsudin MW, Kadhum AAH, Talib MZM (2005) The kinetics of polyphenol degradation during the drying of Malaysian cocoa beans. Int J Food Sci Technol 40:323–331

Majdi A-M, Aljarrah M, Rababah T (2016) Application of hybrid neural fuzzy system (ANFIS) in food processing and technology. Food Eng Rev 8(3):351–366

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 46:71–78

Mujumdar AS (2006) Innovation and globalization in drying R&D. Proc 15th Int Drying Symp IDS 14:3–17

Nassef AM, Sayed ET, Rezk H, Abdelkareem MA, Rodriguez C, Olabi AG (2018) Fuzzy-modeling with particle warm optimization for enhancing the production of biodiesel from microalga. Energ Source Part A: Recovery Util Environ Effects 41(17):1–10

O’Callaghan JR, Menzies DJ, Bailey PH (1971) Digital simulation of agricultural dryer performance. J Agric Eng Res 16:223–244

Oke DO, Omotayo KF (2012) Effect of forced-air artificial intermittent drying on cocoa beans in South-Western Nigeria. J Cereals Oil Beans 3(1):1–5

Page G (1949) Factors influencing the maximum rates of air-drying shelled corn in thin layers. M.S. Dissertation. Purdue University, Lafayette

Paramo D, Garcia-Alamilla P, Salgado-Cervantes MA, Robles-Olvera VJ, Rodriguez-Jimenes (2010) Mass transfer of water and volatile fatty acids in cocoa beans during drying. J Food Eng 99:276–283

Rahman SMA, Hoque ME, Rahman S, Hasanuzzaman M (2015) Osmotic dehydration of pumpkin using response surface methodology – influences of operating conditions on water loss and solute gain. J Bioprocess Biotech 5:1–6

Rahman SMA, Hoque ME, Rahman S, Rahman MM (2017) A novel vortex tube assisted atmospheric freeze-drying system: effect of osmotic pre- treatment on biological products. J Food Process Eng 40(3):1–11

Saltini R, Akkerman R, Frosch S (2013) Optimizing chocolate production through trace- ability: a review of the influence affirming practices on cocoa bean quality. Food Control 29:167–187

Saravacos GD, Maroulis ZB (2001) Transport properties of foods. Marcel Dekker Inc, New York

Shahpour JR, Mohammad K, Vali RS (2018) Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf 54(11):3361–3374

Sharaf-Eldeen YI, Blaisdell JL, Hamdy MY (1980) A model for ear corn drying. Trans ASAE 5:1261–1265

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern 15:116

Therdthai N, Zhou WBN (2009) Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J Food Eng 91(3):482–489

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Yang T, Yong L, Ruiyun Z, Dinh-Toi C (2016) Neuro-fuzzy modeling to predict physicochemical and microbiological parameters of partially dried cherry tomato during storage: effects on water activity, temperature and storage time. J Food Sci Technol 53(10):3685–3694

Acknowledgments

The authors would like to thank the University of Sharjah for the financial support to conduct this study (Project no: 1602040652-P). Besides, the authors have the deepest gratitude to Assistant Professor Andrew Joseph Power at the University of Sharjah for his kind proofreading providing beneficial comments that significantly helped to improve the overall quality of this paper. The authors would also like to thank Eng. Salah Issa Elsayed for his technical supports provided during this study.

Funding

This research was funded by The University of Sharjah, 1602040652-P”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahman, S.M.A., Nassef, A.M., Rezk, H. et al. Experimental investigations and modeling of vacuum oven process using several semi-empirical models and a fuzzy model of cocoa beans. Heat Mass Transfer 57, 175–188 (2021). https://doi.org/10.1007/s00231-020-02943-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02943-5