Abstract

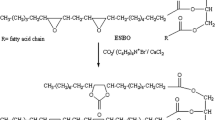

The utilisation of palm oil-based polymers as biomaterials has received considerable interest to support further expansion in the biomedical field as they pose the potential capability of competing with synthetic polymers per their physicochemical, thermal, and crystallinity properties. In this study, the synthesis of a new green biopolymer, namely acrylated palm olein (APO) from a palm oil-based precursor, was developed. The APO was synthesised via the ring-opening process of the epoxidised palm olein (EPOo) with acrylic acid and triethylamine. The acrylation process produced an APO of a high yield (86.64%) with a molecular weight of 1750 Da. The ester group representing the APO was confirmed through the proton nuclear magnetic resonance (1H-NMR), carbon-13 nuclear magnetic resonance (13C-NMR) and Fourier transform infrared (FTIR), which revealed the promising biodegradable point of the APO molecular structure. Meanwhile, thermal and crystallisation profiles of the APO showed a single-stage decomposition pattern and its triglycerides (TAGs) crystal formation and melting behaviour. As a result, the desired APO polymer was obtained, which possessed potential biodegradable chemical functional group, amorphous, and low molecular weight properties.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

References

Salih AM, Ahmad M, Ibrahim NA, Mohd Dahlan KZ, Tajau R, Mahmood MH, Wan Yunus WMZ (2015) Synthesis of radiation curable palm oil-based epoxy acrylate: NMR and FTIR spectroscopic investigations. Molecules 20:14191–14211

Cheong MY, Ooi TL, Ahmad S, Wan Yunus WMZ, Kuang D (2009) Synthesis and characterization of palm-based resin for UV coating. J Appl Polym Sci 111(5):2353–2361

Mahmood MH, Tajau R, Salleh MZ, Che Ismail R (2011) Method for manufacturing palm oil based hydroxyl containing products for use in making polyurethane materials. Malaysia Patent MY-142814-A

Tajau R, Mahmood MH, Salleh MZ, Mohd Dahlan KZ, Che Ismail R, Muhammad Faisal S, Sheikh Abdul Rahman SMZ (2013) Production of UV-curable palm oil resins/oligomers using laboratory scale and pilot scale systems. Sains Malays 42(4):459–467

Islam MR, Hossen Beg MD, Jamari SS (2014) Development of vegetable-oil-based polymers. J Appl Polym Sci 131(18):1–13. https://doi.org/10.1002/APP.40787

Azam Ali M, Ooi TL, Ahmad S, Ishiaku US, Mohd Ishak ZA (1999) New UV-curable acrylated polyester prepolymers from palm oil based products. International Atomic Energy Agency, Vienna

Gan Y, Jiang X (2014) Photo-cured materials from vegetable oils. In: Liu Z, Kraus G (eds) Green materials from plant oils. Royal Society of Chemistry, Cambridge, pp 1–27. https://doi.org/10.1039/9781782621850-00001

Yin S, O'brien ME, Wang MZ (2011) Polyol acrylates for use in energy curable inks. Northfield, United State Patent US9394401B2

Badri K (2012) Biobased polyurethane from palm kernel oil-based polyol. In: Zafar F, Sharmin E (eds) Polyurethane. InTech, Rijeka, pp 447–470. https://doi.org/10.5772/47966

Salleh MZ, Badri K, Mahmood MH, Ahmad S (2010) Synthesis of UV-curable hyperbranched urethane acrylate from palm oil oleic acid. J Nucl Relat Technol 7(2):38–48

Tajau R, Rohani R, Wan Isahak WNR, Salleh MZ (2017) Palm oil-based precursors for development of polymeric delivery system. Malays J Anal Sci 21(2):496–511

Habib F, Bajpai M (2011) Synthesis and characterization of acrylated epoxidized soybean oil for UV cured coatings. Chem Chem Technol 5(3):317–326

Li P, Ma S, Dai J, Liu X, Jiang Y, Wang S, Wei J, Chen J, Zhu J (2017) Itaconic acid as a green alternative to acrylic acid for producing a soybean oil-based thermoset: synthesis and properties. ACS Sustain Chem Eng 5(1):1228–1236

Li YT, Yang LT, Zhang H, Tang ZJ (2017) Synthesis and properties of a novel bio-based polymer from modified soybean oil. IOP Conf Ser: Mater Sci Eng 170(2017):1–7. https://doi.org/10.1088/1757-899X/170/1/012010

Saithai P, Lecomte J, Dubreucq E, Tanrattanakul V (2013) Effects of different epoxidation methods of soybean oil on the characteristics of acrylated epoxidized soybean oil-co-poly(methyl methacrylate) copolymer. eXPRESS Polym Lett 7(11):910–924

Mohd Nor H, Mahmood MH, Kifli H, Abdul Rahman M, Rafie A (1990) The use of epoxidised palm oil products (EPOP) for the synthesis of radiation curable resins 1. Synthesis of epoxidised RBD palm olein acrylate. J Sains Nukl Malays 8(2):149–155

Tajau R, Mohd Dahlan KZ, Mahmood MH, Salleh MZ (2013) A composition susceptible to irradiation for use as a compound carrier. Malaysia Patent Application Number PI 2013701558

Acik G (2020) Bio-based poly(e-caprolactone) from soybean-oil derived polyol via ring-opening polymerization. J Polym Environ 28:668–675

Kulsiriswad S, Saravari O, Srikulkit K (2018) Properties of UV-curable printing screen printing inks oligolactide acrylates. J Met Mater Miner 28(2):55–62

Mohd D, Tajau R, Abdullah Z, Umar KNK, Mohd Nor H (2002) Synthesis of EB-curable natural rubber-based oligomer. Nucl Sci J Malays 20(1&2):56–63

Czub P, Franek I (2013) Epoxy resins modified with palm oil derivatives-preparation and properties. Polimery 58(2):135–139

Abd Rahman N, Badri K, Nik Salleh NG (2014) UV-curable acrylated coating from epoxidized palm oil. AIP Conf Proc 1614:439–445. https://doi.org/10.1063/1.4895237

Tajau R, Wan Yunus WMZ, Mohd Dahlan KZ, Mahmood MH, Hashim K, Ismail M, Salleh M, Che Ismail R (2013) Radiation-induced formation of acrylated palm oil nanoparticle using pluronic f-127 microemulsion system. Pertanika J Sci Technol 21(1):127–134

Karami Z, Zohuriaan-Mehr MJ, Kabiri K, Ghasemi Rad N (2019) Bio-based thermoset alloys from epoxy acrylate, sesame oil- and castor oil-derived resins: renewable alternatives to vinyl ester and unsaturated polyester resins. Polym Renew Resour 10(1–3):27–44

Acik G, Karatavuk AO (2020) Synthesis, properties and biodegradability of cross-linked amphiphilic poly(vinyl acrylate)-poly(tert-butyl acrylate)s by photo-initiated radical polymerization. Eur Polym J 127:109599

Stankevich KS, Danilenko N, Gadirov RM, Goreninskii SI, Tverdokhlebov SI, Filimonov VD (2017) A new approach for the immonilization of poly(acrylic) acid as a chemically reactive cross-linker on the surface of poly(lactic) acid-based biomaterials. Mater Sci Eng: C 71:862–869

Mishra B, Upadhyay M, Reddy Adena SK, Vasant BG, Muthu MS (2017) Hydrogels: an introduction to a controlled drug delivery device, synthesis and application in drug delivery and tissue engineering. Aust J Biomed Eng 4(1):1037

Gentile P, Chiono V, Carmagnola I, Hatton PV (2014) An overview of poly(lactic-co-glycolic) acid (plga)-based biomaterials for bone tissue engineering. Int J Mol Sci 15:3640–3659

Woodruff MA, Hutmacher DW (2010) The return of a forgotten polymer-polycaprolactone in the 21st century. Prog Polym Sci 35(10):1217–1256. https://doi.org/10.1016/j.progpolymsci.2010.04.002

Makadia HK, Siegel SJ (2011) Poly lactic-co-glycolic acid (PLGA) as biodegradable controlled drug delivery carrier. Polymers (Basel) 3(3):1377–1397

Natu MV, de Sousa HC, Gil MH (2010) Effects of drug solubility, state and loading on controlled release in bicomponent electrospun fibers. Int J Pharm 397(1–2):50–58

Llorens E, Armelin E, Mar Pérez-Madrigal M, Valle LJ, Alemán C, Puiggalí J (2013) Nanomembranes and nanofibers from biodegradable conducting polymers. Polymers 5:1115–1157

Mahapatro A, Singh DK (2011) Biodegradable nanoparticles are excellent vehicle for site directed in-vivo delivery of drugs and vaccines. J Nanobiotechnol 9(55):1–11

Bolley DS, Gall RJ, Goldsmith WF, Maerker G, Pohle WD, Sobatzki RJ, Walker RO, Barlow DO (1964) Report of the epoxidized oils subcommittee on oxirane oxygen. J Am Oil Chem Soc 41(1):86

ASTM (2011) D974: standard test method for acid and base number by color-indicator titration. ASTM International, West Conshohocken, Pennsylvania

ASTM (1979) ASTM D1962–67: test for saponification value of drying oils, fats and polymerized fatty acids, vol 29. ASTM International, Philadelphia

AOCS (1998) Methods Cd 1–25: iodine value of fats and oils Wijs method. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. American Oil Chemists' Society (AOCS), Champaign

Beare-Rogers J, Dieffenbacher A, Holm JV (2001) Lexicon of lipid nutrition. Pure Appl Chem 73(4):685–744

Nrc NRC (1972) Food chemicals codex, 2nd edn. National Academic of Sciences, Washington

Lubrizol (2015) Lubrizol test procedure. TP-TM-006C: Determination of saponification value:1–2

ASTM (1999) ASTM D4274–99: standard test methods for testing polyurethane raw materials: determination of hydroxyl numbers of polyols. ASTM International, West Conshohocken, Pennsylvania

Ionescu M (2005) Chemistry and technology of polyols for polyurethanes. Smithers Rapra Technology Limited, Shawbury

Brookfield (2015) Operating instructions Brookfield Digital Viscometer Model DV-II+Pro PROGRAMMABLE VISCOMETER Manual No. M/03-165-C0508W. Brookfield Engineering Laboratories Inc., Middleboro

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulose performance. Biotechnol Biofuels 3(10):1–10. https://doi.org/10.1186/1754-6834-3-10

Ciolacu D, Ciolacu F, Popa VI (2011) Amorphous cellulose-structure and characterization. Cellul Chem Technol 45:13–21

Tajau R (2013) Radiation synthesis and characterization of micro and nano particles of acrylated palm olein for use in drug delivery. Master Degree, Universiti Putra Malaysia, Selangor

Wong JL, Aung MM, Lim HN, Md. Jamil SNA (2017) Spectroscopic analysis of epoxidised jatropha oil (ejo) and acrylated epoxidised jatropha oil (aejo). Pertanika J Trop Agric Sci 40(3):435–448

Giita Silverajah VS, Ibrahim NA, Wan Yunus WMZ, Abu Hassan H, Chieng BW (2012) A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int J Mol Sci 13:5878–5898

Govindarajan T, Shandas R (2014) A Survey of surface modification techniques for next-generation shape memory polymer stent devices. Polymers 6:2309–2331. https://doi.org/10.3390/polym6092309

Mackiewicz N, Nicolas J, Handké N, Noiray M, Mougin J, Daveu C, Lakkireddy HR, Bazile D, Couvreur P (2014) Precise engineering of multifunctional pegylated polyester nanoparticles for cancer cell targeting and imaging. Chem Mater 26:1834–1847. https://doi.org/10.1021/cm403822w

Miao S, Zhu W, Castro NJ, Nowicki M, Zhou X, Cui H, Fisher JP, Zhang LG (2016) 4D printing smart biomedical scaffolds with novel soybean oil epoxidized acrylate. Sci Rep 6:1–10

Yang XJ, Li SH, Xia JL, Song J, Huang K, Li M (2015) Renewable myrcene-based UV-curable monomer and its copolymers with acrylated epoxidized soybean oil: design, preparation, and characterization. BioResources 10(2):2130–2142

Liu ZS, Erhan SZ (2010) Ring-opening polymerization of epoxidized soybean oil. J Am Oil Chem Soc 87:437–444. https://doi.org/10.1007/s11746-009-1514-0

Yakushin V, Stirna U, Bikovens O, Misane M, Sevastyanova I, Vilsone D (2014) Synthesis and characterization of novel polyurethanes based on vegetable oils amide and ester polyols. Mater Sci 20(3):1320–1392

Zieleniewska M, Auguscik M, Prociak A, Rojek P, Ryszkowska J (2015) Polyurethane-urea substrates from rapeseed oil-based polyol for bonetissue cultures intended for application in tissue engineering. Polym Degrad Stab 108:241–249

Ang KP, Lee CS, Cheng SF, Chuah CH (2013) Synthesis of palm oil-based polyester polyol for polyurethane adhesive production. J Appl Polym Sci 131(6):1–8. https://doi.org/10.1002/APP.39967

Caillol S, Desroches M, Boutevin G, Loubat C, Auvergne R, Boutevin B (2012) Synthesis of new polyester polyols from epoxidized vegetable oils and biobased acids. Eur J Lipid Sci Technol 114:1447–1459

Narváez PC, Rincón SM, Castañeda LZ, Sánchez FJ (2008) Determination of some physical and transport properties of palm oil and of its methyl esters. Lat Am Appl Res 38:1–6

Sato K, Ueno S (2005) Polymorphism in fats and oils. In: Shahidi F (ed) Bailey’s industrial oil and fat products-edible oil and fat products: chemistry, properties, and health effects, vol 1, 6th edn. Wiley, New York, pp 77–120

Sato K (2012) Polymorphic properties of palm oil and its major component triacyglycerols. In: Lai OM, Tan CP, Akoh CC (eds) Palm oil: production, processing, characterization, and uses, 1st edn. Elsevier, Amsterdam, pp 393–429

Nassu RT, Guaraldo Gonçalves LA (1999) Determination of melting point of vegetable oils and fats by differential scanning calorimetry (DSC) technique. Grasas Aceites 50(1):16–22

Tan CP, Che Man YB (2000) Differential scanning calorimetric analysis of edible oils: comparison of thermal properties and chemical composition. J Am Oil Chem Soc 77(2):143–155

Teles dos Santos M, Gerbau V, Le Roux GAC (2012) Comparison of predicted and experimental DSC curves for vegetable oils. Thermochim Acta 545:96–102

Omar Z, Hishamuddin E, Mat Sahri M, Mohamad Fauzi SH, Mat Dian NLH, Ramli MR, Abd Rashid N (2015) Palm oil crystallisation: a review. J Oil Palm Res 27(2):97–106

Daud FN, Ahmad A, Badri K (2014) An investigation on the properties of palm-based polyurethane solid polymer electrolyte. Int J Polym Sci 2014:1–5. https://doi.org/10.1155/2014/326716

Igwebike-Ossi CD (2017) X-ray techniques. In: Ali A (ed) Failure analysis and prevention. InTechOpen, Rijeka, pp 153–172. https://doi.org/10.5772/intechopen.72447

Karak N (2012) Vegetable oil-based polyesters. In: Karak N (ed) Vegetable oil-based polymers: properties, processing and applications. Woodhead Publishing Limited, Cambridge, pp 96–125

Daud FN, Ahmad A, Badri K (2013) Preparation and characterization of plasticized palm-based polyuretahne solid polymer electrolyte. AIP Conf Process 1571:775–781. https://doi.org/10.1063/1.4858749

Alqaheem Y, Alomair AA (2020) Microscopy and spectroscopy technique for characterization of polymeric membranes. Membranes 10(2):33. https://doi.org/10.3390/membranes10020033

Zhang X, Li L, Xie H, Liang Z, Su J, Liu G, Li B (2014) Effect of temperature on the crystalline form and fat crystal network of two model palm oil-based shortenings during storage. Food Bioprocess Technol 7:887–900

Omar Z, Hishamuddin E, Kanagaratnam S, Abd Rashid N, Marangoni AG (2018) Dynamics of polymorphic tranformations in palm oil, palm stearin and palm kernel oil characterizaed by coupled powder xrd-dsc. J Oleo Sci 67(6):737–744. https://doi.org/10.5650/jos.ess17168

Zhang MC, Guo BH, Xu J (2017) A review on polymer crystallization theories. Crystals 7(4):1–37. https://doi.org/10.3390/cryst7010004

Dinarvand R, Sepehri N, Manoochehri S, Rouhani H, Atyabi F (2011) Polylactide-co-glycolide nanoparticles for controlled delivery of anticancer agents. Int J Nanomed 6:877–895

Woodard LN, Grunlan MA (2018) Hydrolytic degradation and erosion of polyester biomaterials. ACS Macro Lett 7(8):976–982

Acknowledgements

The authors gratefully acknowledge the Malaysia Nuclear Agency for materials and instruments support under the Radiation Processing Technology Division (Project code: NM-R&D-15-01), the research funds from Universiti Kebangsaan Malaysia (UKM) of DIP/2019/012, and the Ministry of Higher Education of Malaysia of FRGS/1/2018/TK02/UKM/02/2, as well as additional support from the Research Centre for Sustainable Process Technology (CESPRO) and Department of Chemical and Process Engineering, UKM Bangi. Finally, the first author would like to thank Jabatan Perkhidmatan Awam (JPA) for the PhD scholarship.

Funding

This study was funded by the Malaysia Nuclear Agency (NM-R&D-15-01), Universiti Kebangsaan Malaysia (DIP/2019/012), and Ministry of Higher Education (FRGS/1/2018/TK02/UKM/02/2).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analyses were performed by RT, RR and MZS. The first draft of the manuscript was written by RT and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tajau, R., Rohani, R. & Salleh, M.Z. Physicochemical and Thermal Properties of Acrylated Palm Olein as a Promising Biopolymer. J Polym Environ 28, 2734–2748 (2020). https://doi.org/10.1007/s10924-020-01797-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01797-6