Abstract

A multiscale clustering-based topology optimization for thermo-elastic lattice structures is studied based on the extended multiscale finite element method (EMsFEM). The strain energy of thermo-elastic lattice structures is chosen as the objective function. The microstructural configuration and the macrostructural distribution of the thermo-elastic lattice material are designed through topology optimization concurrently. The K-means clustering-based method is proposed to group the microstructures of the lattice materials. The effects of the number of clusters (groups), magnitude of the thermal loads, size factor of the microstructure, and material volume fraction on the optimization results are discussed. The results show that the clustering-based multiscale design optimization is superior to the classical multiscale design optimization of lattice structures.

Similar content being viewed by others

References

Cheng GD, Olhoff N (1981) An investigation concerning optimal design of solid elastic plates. Int J Solids Struct 17:305–323

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71:197–224

Allaire G (2012) Shape optimization by the homogenization method. Springer, India

Sigmund O (2001) A 99 line topology optimization code written in Matlab. Struct Multidiscipl Optim 21:120–127

Rodrigues H, Fernandes P (1995) Material based model for topology optimization of thermo-elastic structures. Int J Numer Methods Eng 38:1951–1965

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. J Mech Phys Solids 45:1037–1067

Xia Q, Wang MY (2008) Topology optimization of thermo-elastic structures using level set method. Comput Mech 42:837–857

Pedersen P, Pedersen NL (2010) Strength optimized designs of thermo-elastic structures. Struct Multidiscipl Optim 42:681–691

Deng J, Yan J, Cheng G (2013) Multi-objective concurrent topology optimization of thermo-elastic structures composed of homogeneous porous material. Struct Multidiscipl Optim 47:583–597

Zhang W, Yang J, Xu Y, Gao T (2014) Topology optimization of thermo-elastic structures: mean compliance minimization or elastic strain energy minimization. Struct Multidiscipl Optim 49:417–429

Deaton JD, Grandhi RV (2013) Stress-based topology optimization of thermal structures. Struct Multidiscipl Optim 53(2):253–270

Gao T, Xu P, Zhang W (2016) Topology optimization of thermo-elastic structures with multiple materials under mass constraint. Comput Struct 173:150–160

Giraldo-Londoñoa O, Mirabella L, Dalloro L, Paulino GH (2020) Multi-material thermomechanical topology optimization with applications to additive manufacturing: design of main composite part and its support structure. Comput Methods Appl Mech Eng 363:112812

Takalloozadeh M, Yoon GH (2017) Development of Pareto topology optimization considering thermal loads. Comput Methods Appl Mech Eng 317:554–579

Park CY, Zohdi TI (2019) Numerical modeling of thermo-mechanically induced stress in substrates for droplet-based additive manufacturing processes. J Manuf Sci Eng 141(6):061001

Evans AG, Hutchinson JW, Fleck NA, Ashby M, Wadley H (2001) The topological design of multifunctional cellular metals. Prog Mater Sci 46:309–327

Zhang X, Vyatskikh A, Gao H, Greer JR, Li X (2019) Lightweight, flaw-tolerant, and ultra strong nano architected carbon. Proc Natl Acad Sci 116(14):6665–6672

Zhang Y, Xiao M, Li H, Gao L, Chu S (2018) Multiscale concurrent topology optimization for cellular structures with multiple micro-structures based on ordered SIMP interpolation. Comput Mater Sci 155:74–91

Zegard T, Glaucio HP (2015) GRAND3—Ground structure based topology optimization for arbitrary 3D domains using MATLAB. Struct Multidiscipl Optim 52:1161–1184

Zhang X, Ramos AS, Paulino GH (2017) Material nonlinear topology optimization using the ground structure method with a discrete filtering scheme. Struct Multidiscipl Optim 55(6):2045–2072

Kazemi H, Vaziri A, Norato JA (2020) Multi-material topology optimization of lattice structures using geometry projection. Comput Methods Appl Mech Eng 363:112895

Alexandersen J, Lazarov BS (2015) Topology optimization of manufacturable microstructural details without length scale separation using a spectral coarse basis preconditioner. Comput Methods Appl Mech Eng 290:156–182

Alexandersen J, Lazarov BS (2015) Tailoring macroscale response of mechanical and heat transfer systems by topology optimization of microstructural details. In: Lagaros N, Papadrakakis M (eds) Engineering and Applied Sciences Optimization, vol 38. Computational Methods in Applied Sciences. Springer, Cham

Hou TY, Wu XH (1997) A multiscale finite element method for elliptic problems in composite materials and porous media. J Comput Phys 134:169–189

Efendiev Y, Hou T (2007) Multiscale finite element methods for porous media flows and their applications. Appl Numer Math 57:577–596

Zhang H, Lv J, Zheng Y (2010) A new multiscale computational method for mechanical analysis of closed liquid cell materials. Comput Modell Eng Sci 68:55–93

Yan J, Hu W, Duan Z (2015) Structure/material concurrent optimization of lattice materials based on extended multiscale finite element method. Int J Multiscale Comput Eng 13:73–90

Yan J, Yang S, Yang C (2014) Multiscale analysis of thermal stress of lattice materials and its size effects. J Therm Stress 37:885–904

Liu L, Yan J, Cheng G (2008) Optimum structure with homogeneous optimum truss-like material. Comput Struct 86:1417–1425

Guo X, Zhang W, Zhong W (2014) Doing topology optimization explicitly and geometrically—a new moving morphable components based framework. J Appl Mech 81(8):081009

Bendsøe MP, Sigmund O (2004) Topology optimization by distribution of isotropic material. Springer, New York

Cadman JE, Zhou S, Chen Y, Li Q (2013) On design of multi-functional microstructural materials. J Mater Sci 48:51–66

Long K, Yuan PF, Xu S, Xie YM (2018) Concurrent topological design of composite structures and materials containing multiple phases of distinct Poisson’s ratios. Eng Optim 50(4):599–614

Rodrigues H, Guedes JM, Bendsoe M (2002) Hierarchical optimization of material and structure. Struct Multidiscipl Optim 24:1–10

McMenamin PG, Quayle MR, McHenry CR, Adams JW (2014) The production of anatomical teaching resources using three-dimensional (3D) printing technology. Anatom Sci Educ 7:479–486

Liu Z, Bessa M, Liu WK (2016) Self-consistent clustering analysis: an efficient multi-scale scheme for inelastic heterogeneous materials. Comput Methods Appl Mech Eng 306:319–341

Gao J, Luo Z, Li H, Gao L (2019) Topology optimization for multiscale design of porous composites with multi-domain microstructures. Comput Methods Appl Mech Eng 344:451–476

Xu L, Cheng G (2018) Two-scale concurrent topology optimization with multiple micro materials based on principal stress orientation. Struct Multidiscipl Optim 57:2093–2107

Kai L, Detwiler D, Tovar A (2017) Optimal design of nonlinear multimaterial structures for crashworthiness using cluster analysis. J Mech Des 139(10):101401

Takezawa A, Zhang X, Kato M, Kitamura M (2019) Method to optimize an additively-manufactured functionally-graded lattice structure for effective liquid cooling. Addit Manuf 28:285–298

Cheng L, Liang X, Belski Eric, Wang X, Jennifer MS, Steve L, Albert T (2018) Natural frequency optimization of variable-density additive manufactured lattice structure: theory and experimental validation. J Manuf Sci Eng 140(10):105002

Zohdi T (2018) Dynamic thermomechanical modeling and simulation of the design of rapid free-form 3D printing processes with evolutionary machine learning. Comput Methods Appl Mech Eng 331:343–362

Li H, Kafka OL, Gao J, Yu C, Nie Y, Zhang L, Tajdari M, Tang S, Guo X, Li G (2019) Clustering discretization methods for generation of material performance databases in machine learning and design optimization. Comput Mech 64(2):281–305

Fan HL, Zeng T, Fang DN, Yang W (2010) Mechanics of advanced fiber reinforced lattice composites. Acta Mech Sin 26:825–835

Wadley H, Dharmasena K, Chen Y, Dudt P, Knight D, Charette R, Kiddy K (2008) Compressive response of multilayered pyramidal lattices during underwater shock loading. Int J Impact Eng 35:1102–1114

Chang DX, Zhang XD, Zheng CW (2009) A genetic algorithm with gene rearrangement for K-means clustering. Pattern Recogn 42:1210–1222

Xu S, Cai Y, Cheng G (2010) Volume preserving nonlinear density filter based on heaviside functions. Struct Multidiscipl Optim 41:495–505

Boggs PT, Tolle JW (1995) Sequential quadratic programming. Acta Numer 4:1–51

Garner E, Kolken HM, Wang CC, Zadpoor AA, Wu J (2019) Compatibility in microstructural optimization for additive manufacturing. Addit Manuf 26:65–75

Sigmund O (1995) Tailoring materials with prescribed elastic properties. Mech Mater 20(4):351–368

Cheng GD, Cai YW, Xu L (2013) Novel implementation of homogenization method to predict effective properties of periodic materials. Acta Mech Sin 29(4):550–556

Acknowledgements

Financial supports for this research were provided by the National Natural Science Foundation of China (Nos. 11672057, U1906233), the Key R&D Program of Shandong Province (2019JZZY010801), the 111 project (B14013). These supports are gratefully acknowledged. Helpful suggestions given by Prof. Gengdong Cheng of Dalian University of Technology are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Equivalent stiffness matrix of the truss microstructure

The rod m–n within the truss unit cell in the local and global coordinate systems is shown in Fig. 20. According to Eqs. (3–6), the deformation \( \Delta L \) of the rod m–n is given as

where

where \( \theta^{\text{e}} \) is the trigonometric function between the microrod and X axis.

Only consider the body load, the potential energy of the thermo-elastic lattice structure can be written as follows,

The elemental strain–displacement can be expressed as

Substitute Eq. (A1–A3) into Eq. (A4), then the potential energy can be expressed as

Then the equivalent stiffness matrix and thermal load by assembling the corresponding components of each rod in the microstructure are given as

where \( k_{\text{e}}^{i} \) denotes the elastic stiffness matrix of the microrod in the local coordinate.

Appendix B: L-shaped beam example

An L-shaped beam, shown in Fig. 21, is considered as an example for optimization with the proposed clustering-based multiscale optimization method. The upper and right edges are fixed. A mechanical load is applied at the node in the lower left. Horizontal distributed loads are applied to the bottom left corner as \( F_{x} = - 200 \times 8 = 1600 \). Similarly, vertical distributed loads are applied to the bottom left corner as \( F_{y} = - 200 \times 8 = 1600 \). A uniform temperature rise of \( \Delta T \) = 50 °C is applied to the whole structure. The base material available for the micro unit cell is \( {\text{V}}^{\text{MI}} = 5.8284. \) For the geometry, a = 15, and the area of each macro-element is unity (the length of each side of the macro-element was unity). The mesh is composed of 675 macro-elements. Therefore, the area of macro design domain is \( V^{MA} = 675 \). The amount of base material is retained during the optimization process. The upper limit of base material volume fraction was \( \overline{\varphi } \) = 0.1, which is kept as an active constraint. The other parameters are the same as in the example presented in Sect. 5.

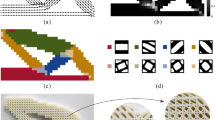

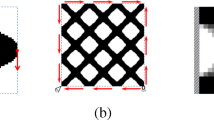

The strain energy with the classical multiscale topology optimization is 60.07. The configuration of the lattice structure of the classical multiscale optimization with uniform microstructures is shown in Fig. 22. The strain energies with the clustering-based multiscale topology optimization by the average clustering-based method and the K-means clustering-based method with four clusters were 55.78 and 54.90, respectively. The K-means clustering-based multiscale optimization is better than the average clustering-based multiscale optimization. The results of the clustering-based multiscale designed by the average clustering-based method and the K-means clustering-based method are shown in Figs. 23, 24, respectively. They are both assembled with three types of microstructures as shown in Figs. 23b, 24b, respectively. The clustering-based multiscale optimization design of the lattice structure is clearly superior to that by the classical multiscale optimization. Furthermore, the clustering-based multiscale design optimization can achieve a better distribution of the base material. The macro-configuration from the three multiscale optimizations is the same, namely the oblique V-shaped configuration.

Rights and permissions

About this article

Cite this article

Yan, J., Sui, Q., Fan, Z. et al. Clustering-based multiscale topology optimization of thermo-elastic lattice structures. Comput Mech 66, 979–1002 (2020). https://doi.org/10.1007/s00466-020-01892-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-020-01892-4