Abstract

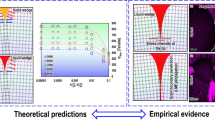

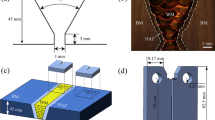

This study aims to explore the mode of Zn transportation and the failure mechanism of cracking associated with liquid metal embrittlement (LME) using fractography as the key technique. A three-point bend test was performed on a TRIP steel resistance spot weld to open the LME crack in the form of a free fracture surface for the fractographic investigation. The presence of liquid Zn on the fracture surface was revealed by the Fe-Zn phase transformation and the spike-like morphology of the residual Zn, confirming that the mode of Zn transportation in LME cracks was liquid penetration through the austenite grain boundary. In addition, the fractography of the bend test samples and electron backscattered diffraction of the cracks revealed the failure mode of the LME crack as a complete intergranular brittle fracture without the generation of any microplasticity. Thus, the underlying failure mechanism of cracking in Zn-LME can be explained by the Stoloff-Johnson-Westwood-Kamdar brittle fracture model induced by the decohesion of interatomic bonds. Overall, a dramatic reduction in the interatomic bond strength by lowering the surface energy of the grain boundary with liquid Zn penetration causes the decohesion-induced intergranular brittle cracking.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this moment due to technical or time limitations.

References

Keeler S, Kimchi M (2014) Advanced high-strength steels application guidelines V5.0

Shome M, Tumuluru M (2015) Welding and joining of advanced high strength steels (AHSS)

Marder AR, Marder ARR (2000) The metallurgy of zinc-coated steel. Prog Mater Sci 45:191–271. https://doi.org/10.1016/S0079-6425(98)00006-1

Tumuluru M (2007) The effect of coatings on the resistance spot welding behaviour of 780 MPa DP steel. Weld J 86:161–169

Chun EJ, Lim SS, Kim YT, Nam KS, Kim YM, Park YW, Murugan SP, Park YD (2019) Influence of heat-treated Al–Si coating on the weldability and microstructural inhomogeneity for hot stamped steel resistance nut projection welds. Met Mater Int 25:179–192. https://doi.org/10.1007/s12540-018-0108-5

Ashiri R, Haque MA, Ji CW, shamanian M, Salimijazi HR, Park YD (2015) Supercritical area and critical nugget diameter for liquid metal embrittlement of Zn-coated twining induced plasticity steels. Scr Mater 109:6–10. https://doi.org/10.1016/j.scriptamat.2015.07.006

Murugan SP, Vijayan V, Ji C, Park Y-D (2020) Four types of LME cracks in RSW of Zn-coated AHSS. Weld J 99:75–92

DiGiovanni C, Han X, Powell A, Biro E, Zhou NY (2019) Experimental and numerical analysis of liquid metal embrittlement crack location. J Mater Eng Perform 28:2045–2052

DiGiovanni C, Biro E, Zhou NY (2019) Impact of liquid metal embrittlement cracks on resistance spot weld static strength. Sci Technol Weld Join 24:218–224. https://doi.org/10.1080/13621718.2018.1518363

Wintjes E, DiGiovanni C, He L, Biro E, Zhou NY (2019) Quantifying the link between crack distribution and resistance spot weld strength reduction in liquid metal embrittlement susceptible steels. Weld World 63:807–814. https://doi.org/10.1007/s40194-019-00712-5

Razmpoosh MH, Biro E, Chen DL, Goodwin F, Zhou Y (2018) Liquid metal embrittlement in laser lap joining of TWIP and medium-manganese TRIP steel: the role of stress and grain boundaries. Mater Charact 145:627–633. https://doi.org/10.1016/j.matchar.2018.09.018

Kang H, Cho L, Lee C, De Cooman BC (2016) Zn penetration in liquid metal embrittled TWIP steel. Metall Mater Trans A 47:2885–2905. https://doi.org/10.1007/s11661-016-3475-x

Cho L, Kang H, Lee C, De Cooman BC (2014) Microstructure of liquid metal embrittlement cracks on Zn-coated 22MnB5 press-hardened steel. Scr Mater 90:25–28. https://doi.org/10.1016/j.scriptamat.2014.07.008

Lee H, Jo MC, Sohn SS, Kim SH, Song T, Kim SK, Kim HS, Kim NJ, Lee S (2019) Microstructural evolution of liquid metal embrittlement in resistance-spot-welded galvanized TWinning-Induced Plasticity (TWIP) steel sheets. Mater Charact 147:233–241. https://doi.org/10.1016/j.matchar.2018.11.008

Gordon P (1978) Metal-induced embrittlement of metals-an evaluation of embrittler transport mechanisms. Metall Trans A 9:267–273. https://doi.org/10.1007/BF02646710

Ling Z, Chen T, Kong L, Wang M, Pan H, Lei M (2019) Liquid metal embrittlement cracking during resistance spot welding of galvanized Q&P980 steel. Metall Mater Trans A 50:5128–5142. https://doi.org/10.1007/s11661-019-05388-6

Stoloff NS, Johnston TL (1963) Crack propagation in a liquid metal environment. Acta Metall 11:251–256. https://doi.org/10.1016/0001-6160(63)90180-9

Westwood ARC, Kamder MH (1963) Concerning liquid metal embrittlement, particularly of zinc monocrystals by mercury. Philos Mag 89:787–804. https://doi.org/10.1016/0001-6160(63)90180-9

Joseph B, Picat M, Barbier F (1999) Liquid metal embrittlement: a state-of-the-art appraisal. Eur Phys J Appl Phys 5:19–31. https://doi.org/10.1051/epjap:1999108

Robertson WM (1966) Propagation of a crack filled with liquid metal. Trans Mettal Soc AIME 236:1478–1482

Glikman EE, Goryunov YV (1978) Mechanism of embrittlement by liquid metals and other manifestations of the Rebinder effect in metal systems. Sov Mater Sci 14:355–364

Bhattacharya D, Cho L, van der Aa E, Ghassemi-Armaki H, Pichler A, Findley KO, Speer JG (2020) Transgranular cracking in a liquid Zn embrittled high strength steel. Scr Mater 175:49–54. https://doi.org/10.1016/j.scriptamat.2019.09.006

Lynch SP (1992) Metal-induced embrittlement of materials. Mater Charact 28:279–289. https://doi.org/10.1016/1044-5803(92)90017-C

Hamdane O, Bouquerel J, Proriol-Serre I, Vogt JB (2011) Effect of heat treatment on liquid sodium embrittlement of T91 martensitic steel. J Mater Process Technol 211:2085–2090

Lynch SP (2013) Mechanisms and kinetics of environmentally assisted cracking: current status, issues, and suggestions for further work. In: Metallurgical and Materials Transactions A, pp 1209–1229

Gong X, Marmy P, Volodin A, Amin-Ahmadi B, Qin L, Schryvers D, Gavrilov S, Stergar E, Verlinden B, Wevers M, Seefeldt M (2016) Multiscale investigation of quasi-brittle fracture characteristics in a 9Cr-1Mo ferritic-martensitic steel embrittled by liquid lead-bismuth under low cycle fatigue. Corros Sci 102:137–152. https://doi.org/10.1016/j.corsci.2015.10.003

Toulfatzis AI, Pantazopoulos GA, Paipetis AS (2018) Fracture mechanics properties and failure mechanisms of environmental-friendly brass alloys under impact, cyclic and monotonic loading conditions. Eng Fail Anal 90:497–517. https://doi.org/10.1016/j.engfailanal.2018.04.001

Shih W, King J, Raczowski C (1998) Liquid-copper/zinc embrittlement in alloy 71 8. Weld J:219–222

Murugan SP, Mahmud K, Ji C, Jo I, Park YD (2019) Critical design parameters of the electrode for liquid metal embrittlement cracking in resistance spot welding. Weld World 63:1613–1632. https://doi.org/10.1007/s40194-019-00797-y

Böhne C, Meschut G, Biegler M, Frei J, Rethmeier M (2019) Prevention of liquid metal embrittlement cracks in resistance spot welds by adaption of electrode geometry. Sci Technol Weld Join 25:303–310. https://doi.org/10.1080/13621718.2019.1693731

Sathiyanarayanan S, Marikkannu C, Palaniswamy N (2005) Corrosion inhibition effect of tetramines for mild steel in 1M HCl. Appl Surf Sci 241:477–484. https://doi.org/10.1016/j.apsusc.2004.07.050

Sigler DR (2008) Observations of liquid metal-assisted cracking in resistance spot welds of zinc-coated advanced high-strength steels. In: Sheet Metal Welding Conference XIII, Livonia, pp 1–17

DiGiovanni C, He L, Pistek U, Goodwin F, Biro E, Zhou NY (2020) Role of spot weld electrode geometry on liquid metal embrittlement crack development. J Manuf Process 49:1–9. https://doi.org/10.1016/j.jmapro.2019.11.015

Takahashi M, Nakata M, Imai K, Kojima N, Otsuka N (2017) Liquid metal embrittlement of hot stamped galvannealed boron steel sheet-effect of heating time on crack formation. ISIJ Int 57:1094–1101. https://doi.org/10.2355/isijinternational.ISIJINT-2016-730

Kumar G, Prabhu KN (2007) Review of non-reactive and reactive wetting of liquids on surfaces. Adv Colloid Interf Sci 133:61–89. https://doi.org/10.1016/j.cis.2007.04.009

Chatterjee UK (2001) Environmental degradation of metals. M. Dekker

Wolski K, Laporte V (2008) Grain boundary diffusion and wetting in the analysis of intergranular penetration. Mater Sci Eng A 495:138–146. https://doi.org/10.1016/J.MSEA.2007.10.107

Böllinghaus T, Herold H (2005) Hot cracking phenomena in welds

Ludwig W, Pereiro-López E, Bellet D (2005) In situ investigation of liquid Ga penetration in Al bicrystal grain boundaries: grain boundary wetting or liquid metal embrittlement? Acta Mater 53:151–162. https://doi.org/10.1016/j.actamat.2004.09.012

Read W (1953) Dislocations in crystals. McGraw-Hill Book Company, New York

Ramachandran DC, Murugan SP, Moon J, Lee CH, Park YD (2019) The effect of the hyperstoichiometric Ti/N ratio due to excessive Ti on the toughness of N-controlled novel fire- and seismic-resistant steels. Metall Mater Trans A 50:3514–3527. https://doi.org/10.1007/s11661-019-05266-1

Ryde L (2006) Application of EBSD to analysis of microstructures in commercial steels. Mater Sci Technol 22:1297–1306. https://doi.org/10.1179/174328406X130948

Li X, Zhang J, Akiyama E, Wang Y, Li Q (2018) Microstructural and crystallographic study of hydrogen-assisted cracking in high strength PSB1080 steel. Int J Hydrog Energy 43:17898–17911. https://doi.org/10.1016/j.ijhydene.2018.07.158

Murugan SP, Kim J, Kim J, Wan Y, Lee C, Jeon JB, Park YD (2020) Role of liquid Zn and α-Fe(Zn) on liquid metal embrittlement of medium Mn steel: an ex-situ microstructural analysis of galvannealed coating during high temperature tensile test. Surf Coat Technol 398:126069. https://doi.org/10.1016/j.surfcoat.2020.126069

Hong SH, Kang JH, Kim D, Kim SJ (2020) Si effect on Zn-assisted liquid metal embrittlement in Zn-coated TWIP steels: importance of Fe-Zn alloying reaction. Surf Coatings Technol:393. https://doi.org/10.1016/j.surfcoat.2020.125809

Zeng G, Friedrich B (2009) Influencing the wettability of HSS-steels by addition of alloying elements to the zinc bath. Proc - Eur Metall Conf EMC 2009 3:1183–1200

Kim Y, Lee J, Park J, Jeon SH (2011) Effect of Si content on wettability of dual phase high strength steels by liquid Zn-0.23 wt.%Al. Met Mater Int 17:607–611. https://doi.org/10.1007/s12540-011-0812-x

Tumuluru M (2019) Effect of silicon and retained austenite on the liquid metal embrittlement cracking behavior of GEN3 and high-strength automotive steels. Weld J 98:351S–364S. https://doi.org/10.29391/2019.98.029

Razmpoosh MH, Macwan A, Goodwin F, Biro E, Zhou Y (2020) Role of random and coincidence site lattice grain boundaries in liquid metal embrittlement of iron (FCC)-Zn couple. Metall Mater Trans A 51:3938–3944. https://doi.org/10.1007/s11661-020-05857-3

Razmpoosh MH, Macwan A, Goodwin F, Biro E, Zhou Y (2020) Suppression of liquid-metal-embrittlement by twin-induced grain boundary engineering approach. Materialia 11:100668. https://doi.org/10.1016/j.mtla.2020.100668

Razmpoosh MH, Macwan A, Goodwin F, Biro E, Zhou Y (2020) Crystallographic study of liquid-metal-embrittlement crack path. Mater Lett 267:127511. https://doi.org/10.1016/j.matlet.2020.127511

Author information

Authors and Affiliations

Contributions

Siva Prasad Murugan (conceptualization, methodology, investigation, visualization, writing–original draft); Jong Bae Jeon (software, validation, writing–review and editing); Changwook Ji (software, validation, resources); Yeong-Do Park (conceptualization, methodology, supervision, validation, writing–review and editing).

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Murugan, S.P., Jeon, J.B., Ji, C. et al. Liquid zinc penetration induced intergranular brittle cracking in resistance spot welding of galvannealed advanced high strength steel. Weld World 64, 1957–1969 (2020). https://doi.org/10.1007/s40194-020-00975-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00975-3