Abstract

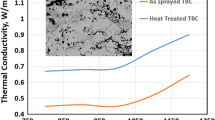

Ti2AlNb alloys are often used to fabricate high-pressure compressor blades and casings in aircraft engines with high thrust/weight ratios. In this study, a three-layered seal coating, NiCrFeAlBN-YSZ-NiCrAl, was prepared by thermal spraying on a titanium alloy (Ti2AlNb) substrate. The microstructure, surface hardness, and bond strength of coatings as well as their thermal cycling performance and abradability under simulated working conditions were investigated. The coating surface hardness was 61 HR15Y and the bond strength was 7.13 MPa. The coating maintained a good bonding to the substrate with no cracks after 40 cycles of water-cooling from 750 °C to room temperature. The abradability of the as-sprayed coating and the coating heat-treated at 750 °C for 200 h was tested against a Ti2AlNb blade at 750 °C, with a tip line speed of 300 m/s, and feed rates of 5, 50 and 480 m/s. The coating wear mechanisms involved micro-ruptures. The Cr2O3 phase formation and a decrease in the number of micropores in the heat-treated coating decreased its abradability.

Similar content being viewed by others

References

C. Leyens and H. Gedanitz, Long-term Oxidation of Orthorhombic Alloy Ti-22Al-25Nb in Air Between 650 and 800 °C, Scr. Mater., 1999, 41(8), p 901-906

J. Małecka, Investigation of the Oxidation Behavior of Orthorhombic Ti2AlNb Alloy, J. Mater. Eng. Perform., 2015, 24(5), p 1834-1840

W.P. Liang, Z. Xu, Q. Miao, X.P. Liu, and Z.Y. He, Double Glow Plasma Surface Molybdenizing of Ti2AlNb, Surf. Coat. Technol., 2007, 201(9), p 5068-5071

H.I. Faraoun, T. Grosdidier, J.L. Seichepine, D. Goran, H. Aourag, C. Coddet, J. Zwick, and N. Hopkins, Improvement of Thermally Sprayed Abradable Coating by Microstructure Control, Surf. Coat. Technol., 2006, 201(6), p 2303-2312

R. Rajendran, Gas Turbine Coatings: An Overview, Eng. Fail. Anal., 2012, 26, p 355-369

F. Ghasripoor, R. Schmid, and M. Dorfman, Abradables Improve Gas Turbine Efficiency, Mater. World, 1997, 5(6), p 328-330

S. Wilson, Thermally Sprayed Abradable Coating Technology for Sealing in Gas Turbines, The Future of Gas Turbine Technology, in 6th International Conference. Brussels, Belgium, 17-18 October 2012, Paper ID Number 51

M. Yi, J. He, B. Huang, and H. Zhou, Friction and Wear Behavior and Abradability of Abradable Seal Coating, Wear, 1999, 231(1), p 47-53

O. Metco, Nickel Chromium Alloy/Boron Nitride Thermal Spray Powders. Technical Report, 2014

J.M. Liu, Y.G. Yu, T. Liu, X.Y. Cheng, J. Shen, and C.H. Li, The Influence of Composition and Microstructure on the Abradability of Aluminum-Based Abradable Coatings, J. Therm. Spray Technol., 2017, 26(6), p 1095-1103

W.H. Xue, S.Y. Gao, D.L. Duan, J.P. Zhang, Y. Liu, and S. Li, Ti6Al4V Blade Wear Behavior During High-Speed Rubbing with NiAl-hBN Abradable Seal Coating, J. Therm. Spray Technol., 2017, 26(3), p 539-553

W.H. Xue, S.Y. Gao, D.L. Duan, L. Wang, Y. Liu, and S. Li, Study on the High-Speed Rubbing Wear Behavior Between Ti6Al4V Blade and Nickel-Graphite Abradable Seal Coating, J. Tribol. Trans. ASME, 2017, 139(2), p 021604

X. Huang, C.X. Cao, J.M. Ma, B. Wang, Y. Gao, and Y.H. Zhou, Titanium Combustion in Aeroengines and Fire-Resistant Titanium Alloys, J. Mater. Eng., 1997, 8, p 11-15

V.G. Anderson, M. Funkhouser, and P. Mcdaniel, Coating for Prevention of Titanium Combustion, Report NO: NASA-CR-165360, FR-13370, 1980, p 1-68

O.E. Kosing, R. Scharl, and H.J. Schmuhl. Design Improvements of the EJ 200 HP Compressor, in Proceedings of ASME TURBO EXPO 2001, New Orleans, Louisiana, USA, 2001, p 5

R.S. Lima and B.R. Marple, Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review, J. Therm. Spray Technol., 2007, 16, p 40-63

C.U. Hardwicke and Y.C. Lau, Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review, J. Therm. Spray Technol., 2013, 22, p 564-576

Q.Y. Lu, J. Shen, Y.G. Yu, X.J. Ren, H.J. Xuan, and T. Liu, Progress on Facilities and Methodology to Evaluate Abradable Seal Coatings, Adv. Mater. Res., 2013, 690-693(5), p 1992-1998

T. Liu, Y.G. Yu, J. Shen, J.M. Liu, and Q.Y. Lu, Study on Wear Mechanism of an AlSi-hexagonal Boron NitrideAbradable Seal Coating, Adv. Mater. Res., 2015, 1095, p 655-661

Z.B. Liu, Seal Coating High Temperature and High Speed Wear Test Technology Research. Master Thesis, Zhejiang University, 2013, p 53-61

M. Bounazef, S. Guessasma, and B.A. Saadi, The Wear, Deterioration and Transformation Phenomena of Abradable Coating BN-SiAl-bounding Organic Element, Caused by the Friction between the Blades and the Turbine Casing, Mater. Lett., 2004, 58(27), p 3375-3380

D. Sporer, S. Wilson, and M. Dorfman, Ceramics for Abradable Shroud Seal Applications, Advanced Ceramic Coatings and Interfaces IV, D. Zhu, H.T. Lin, D. Singh, and J. Salem, Ed., Wiley, New Jersey, 2009, p 39-54

E. Irissou, A. Dadouche, and R.S. Lima, Tribological Characterization of Plasma-Sprayed CoNiCrAlY-BN Abradable Coatings, J. Therm. Spray Technol., 2014, 23(1-2), p 252-261

R.K. Schmid, New High Temperature Abradables for Gas Turbines. Ph.D. Thesis, Swiss Federal Institute of Technology, 1997, p 94-96

M.O. Borel, A.R. Nicoll, H.W. Schlapfer, and R.K. Schmid, The Wear Mechanisms Occurring in Abradable Seals of Gas Turbines, Surf. Coat. Technol., 1989, 39(89), p 117-126

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, X., Yu, Y., Zhang, D. et al. Preparation and Performance of an Abradable NiCrFeAlBN-YSZ-NiCrAl Layered Seal Coating for Aircraft Engines. J Therm Spray Tech 29, 1804–1814 (2020). https://doi.org/10.1007/s11666-020-01082-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01082-x