Abstract

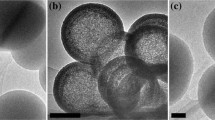

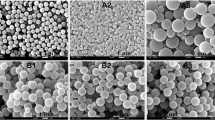

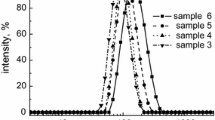

The aim of this study was the synthesis of silica hollow spheres-based materials doped with metal nanoparticles or metal oxides. Two different strategies based on the use of polymer colloids and cetyltrimethylammonium bromide (CTAB) as dual templates were developed. The first strategy involves the use of soap-free emulsion polymerization for the trapping of metal nanoparticles (Ag and Ni) and in the polymer structure. The second strategy exploited carboxyl groups present on the surface of the polymer particles for the adsorption of metal salts (Ni and Fe). A complete porous SiO2 shell was generated around the polymer colloids using a Stöber method and CTAB to guide the silica shell growth. The obtained silica hollow sphere displayed either yolk-shell distribution of the doping elements or a uniform oxide deposit on the interior surface of the silica capsules. The versatility of the synthesis method and the catalytic performance of the materials were demonstrated in the case of Fe@SiO2 for a Fischer-Tropsch process.

Graphical abstract

Similar content being viewed by others

References

Yuan J, Zhou T, Pu H (2010) Nano-sized silica hollow spheres: preparation, mechanism analysis and its water retention property. J Phys Chem Solids 71(7):1013–1019. https://doi.org/10.1016/j.jpcs.2010.04.004

Qiu J, Camargo PHC, Jeong U, Xia Y (2019) Synthesis, transformation, and utilization of monodispersed colloidal spheres. Acc Chem Res 52(12):3475–3487. https://doi.org/10.1021/acs.accounts.9b00490

Snoch W, Tataruch M, Zastawny O, Cichoń E, Gosselin M, Cabana H, Guzik M (2019) Hollow silica microspheres as robust immobilization carriers. Bioorg Chem 93:102813. https://doi.org/10.1016/j.bioorg.2019.02.038

Qiao N, He C, Zhang X, Yang H, Cheng J, Hao Z (2019) Hollow mesoporous silica materials with well-ordered cubic Ia3d mesostructured shell for toluene adsorption. J Porous Mater 26(1):59–68. https://doi.org/10.1007/s10934-018-0611-6

Gorsd MN, Pizzio LR, Blanco MN (2015) Synthesis and characterization of hollow silica spheres. Procedia Mater Sci 8:567–576. https://doi.org/10.1016/j.mspro.2015.04.110

Bao Y, Shi C, Wang T, Li X, Ma J (2016) Recent progress in hollow silica: template synthesis, morphologies and applications. Microporous Mesoporous Mater 227:121–136. https://doi.org/10.1016/j.micromeso.2016.02.040

Zhang S, Xu L, Liu H, Zhao Y, Zhang Y, Wang Q, Yu Z, Liu Z (2009) A dual template method for synthesizing hollow silica spheres with mesoporous shells. Mater Lett 63(2):258–259. https://doi.org/10.1016/j.matlet.2008.10.004

Selvakumar R, Seethalakshmi N, Thavamani P, Naidu R, Megharaj M (2014) Recent advances in the synthesis of inorganic nano/microstructures using microbial biotemplates and their applications. RSC Adv 4(94):52156–52169. https://doi.org/10.1039/C4RA07903E

Grady ZA, Arthur AZ, Wohl CJ (2019) Topological control of polystyrene-silica core-shell microspheres. Colloids Surf A Physicochem Eng Asp 560:136–140. https://doi.org/10.1016/j.colsurfa.2018.10.019

Lin Y-S, Wu S-H, Tseng C-T, Hung Y, Chang C, Mou C-Y (2009) Synthesis of hollow silica nanospheres with a microemulsion as the template. Chem Commun 24:3542–3544. https://doi.org/10.1039/B902681A

Yu L, Pan P, Zhang Y, Zhang Y, Wan L, Cheng X, Deng Y (2019) Nonsacrificial self-template synthesis of colloidal magnetic yolk–shell mesoporous organosilicas for efficient oil/water interface catalysis. Small 15(14):1805465. https://doi.org/10.1002/smll.201805465

Cho Y-S (2016) Fabrication of hollow or macroporous silica particles by spray drying of colloidal dispersion. J Dispers Sci Technol 37(1):23–33. https://doi.org/10.1080/01932691.2015.1022655

Park JC, Bang JU, Lee J, Ko CH, Song H (2010) Ni@SiO2 yolk-shell nanoreactor catalysts: high temperature stability and recyclability. J Mater Chem 20(7):1239–1246. https://doi.org/10.1039/B918446E

Meng Q, Xiang S, Cheng W, Chen Q, Xue P, Zhang K, Sun H, Yang B (2013) Facile synthesis of manganese oxide loaded hollow silica particles and their application for methylene blue degradation. J Colloid Interface Sci 405:28–34. https://doi.org/10.1016/j.jcis.2013.05.025

Shi C, Du G, Wang J, Sun P, Chen T (2020) Polyelectrolyte–surfactant mesomorphous complex templating: a versatile approach for hierarchically porous materials. Langmuir 36(8):1851–1863. https://doi.org/10.1021/acs.langmuir.9b03513

Sood A (2004) Particle size distribution control in emulsion polymerization. J Appl Polym Sci 92(5):2884–2902. https://doi.org/10.1002/app.20231

Liu B, Sun S, Zhang M, Ren L, Zhang H (2015) Facile synthesis of large scale and narrow particle size distribution polymer particles via control particle coagulation during one-step emulsion polymerization. Colloids Surf A Physicochem Eng Asp 484:81–88. https://doi.org/10.1016/j.colsurfa.2015.07.050

Kamiyama M, Koyama K, Matsuda H, Sano Y (1993) Micron-sized polymeric microsphere by suspension polymerization. J Appl Polym Sci 50(1):107–113. https://doi.org/10.1002/app.1993.070500113

Arshady R (1992) Suspension, emulsion, and dispersion polymerization: a methodological survey. Colloid Polym Sci 270(8):717–732. https://doi.org/10.1007/BF00776142

Liu X, Xu Y, Heuts JPA, Debije MG, Schenning APHJ (2019) Monodisperse liquid crystal network particles synthesized via precipitation polymerization. Macromolecules 52(21):8339–8345. https://doi.org/10.1021/acs.macromol.9b01852

Shen S, Sudol ED, El-Aasser MS (1993) Control of particle size in dispersion polymerization of methyl methacrylate. J Polym Sci A Polym Chem 31(6):1393–1402. https://doi.org/10.1002/pola.1993.080310606

Fukui S, Hirai T, Nakamura Y, Fujii S (2020) pH-dependent foam formation using amphoteric colloidal polymer particles. Polymers 12(3):511

Zhang J, Sun Z, Yang B (2009) Self-assembly of photonic crystals from polymer colloids. Curr Opin Colloid Interface Sci 14(2):103–114. https://doi.org/10.1016/j.cocis.2008.09.001

Xu J, Yang Y, Li Y-W (2013) Fischer–Tropsch synthesis process development: steps from fundamentals to industrial practices. Curr Opin Chem Eng 2(3):354–362. https://doi.org/10.1016/j.coche.2013.05.002

Rafati M, Wang L, Dayton DC, Schimmel K, Kabadi V, Shahbazi A (2017) Techno-economic analysis of production of Fischer-Tropsch liquids via biomass gasification: the effects of Fischer-Tropsch catalysts and natural gas co-feeding. Energy Convers Manag 133:153–166. https://doi.org/10.1016/j.enconman.2016.11.051

Cheah S, Jablonski WS, Olstad JL, Carpenter DL, Barthelemy KD, Robichaud DJ, Andrews JC, Black SK, Oddo MD, Westover TL (2016) Effects of thermal pretreatment and catalyst on biomass gasification efficiency and syngas composition. Green Chem 18(23):6291–6304. https://doi.org/10.1039/C6GC01661H

Munnik P, de Jongh PE, de Jong KP (2015) Recent developments in the synthesis of supported catalysts. Chem Rev 115(14):6687–6718. https://doi.org/10.1021/cr500486u

Ce Y, Cheng S, Feng L (1999) Kinetics and mechanism of emulsifier-free emulsion copolymerization: styrene-methyl methacrylate-acrylic acid system. J Polymer Sci Part A Polymer Chem 37(14):2649–2656. https://doi.org/10.1002/(sici)1099-0518(19990715)37:14<2649::aid-pola40>3.0.co;2-l

Mocanu A, Rusen E, Marculescu B, Cincu C (2011) Synthesis and characterization of a hybrid material from self-assembling colloidal particles and carbon nanotubes. Colloid Polym Sci 289(4):387–394. https://doi.org/10.1007/s00396-011-2378-z

Rusen E, Mocanu A, Nistor LC, Dinescu A, Călinescu I, Mustăţea G, Voicu ŞI, Andronescu C, Diacon A (2014) Design of antimicrobial membrane based on polymer colloids/multiwall carbon nanotubes hybrid material with silver nanoparticles. ACS Appl Mater Interfaces 6(20):17384–17393. https://doi.org/10.1021/am505024p

Wu ZG, Munoz M, Montero O (2010) The synthesis of nickel nanoparticles by hydrazine reduction. Adv Powder Technol 21(2):165–168. https://doi.org/10.1016/j.apt.2009.10.012

Pérez LL, Ortiz-Iniesta MJ, Zhang Z, Agirrezabal-Telleria I, Santes M, Heeres HJ, Melián-Cabrera I (2013) Detemplation of soft mesoporous silica nanoparticles with structural preservation. J Mater Chem A 1(15):4747–4753. https://doi.org/10.1039/C3TA01240A

Olenin AY, Nizamov TR, Lisichkin GV (2014) Chemical modification of the surfaces of silver nanoparticles: synthesis of Janus particles. Nanotechnol Russia 9(9):467–473. https://doi.org/10.1134/S1995078014050103

Gallardo OAD, Moiraghi R, Macchione MA, Godoy JA, Pérez MA, Coronado EA, Macagno VA (2012) Silver oxide particles/silver nanoparticles interconversion: susceptibility of forward/backward reactions to the chemical environment at room temperature. RSC Adv 2(7):2923–2929. https://doi.org/10.1039/C2RA01044E

Phan HT, Haes AJ (2019) What does nanoparticle stability mean? J Phys Chem C 123(27):16495–16507. https://doi.org/10.1021/acs.jpcc.9b00913

Prieto G, Tüysüz H, Duyckaerts N, Knossalla J, Wang G-H, Schüth F (2016) Hollow nano-and microstructures as catalysts. Chem Rev 116(22):14056–14119. https://doi.org/10.1021/acs.chemrev.6b00374

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87(9-10):1051–1069. https://doi.org/10.1515/pac-2014-1117

He Y, Li J, Long M, Liang S, Xu H (2017) Tuning pore size of mesoporous silica nanoparticles simply by varying reaction parameters. J Non-Cryst Solids 457:9–12. https://doi.org/10.1016/j.jnoncrysol.2016.11.023

de Smit E, Weckhuysen BM (2008) The renaissance of iron-based Fischer–Tropsch synthesis: on the multifaceted catalyst deactivation behaviour. Chem Soc Rev 37(12):2758–2781. https://doi.org/10.1039/B805427D

Jahangiri H, Bennett J, Mahjoubi P, Wilson K, Gu S (2014) A review of advanced catalyst development for Fischer–Tropsch synthesis of hydrocarbons from biomass derived syn-gas. Catalysis Sci Technol 4(8):2210–2229. https://doi.org/10.1039/C4CY00327F

Funding

Aurel Diacon and Adrian Trifan acknowledge the financial support received from the Competitiveness Operational Programme 2014–2020, Action 1.1.4 Attracting high-level personnel from abroad in order to enhance the RD capacity, project: P_37_471, “Ultrasonic/Microwave Nonconventional Techniques as new tools for nonchemical and chemical processes,” financed by contract: 47/05.09.2016.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 3563 kb)

DLS analysis of SiO2 hollow particles; EDAX mapping of FexOy@SiO2 particles, BET adsorption/desorption isotherms for SiO2 hollow particles and FexOy@SiO2 particles and a short video presenting the retention of catalytic activity for Fe0@SiO2 after testing, which is demonstrated by ignition of the catalyst once exposed to air (demonstrating the pyrophoric characteristic of Feo). (MP4 2385 kb)

Rights and permissions

About this article

Cite this article

Diacon, A., Rusen, E., Trifan, A. et al. Preparation of metal and metal oxide doped silica hollow spheres and the evaluation of their catalytic performance. Colloid Polym Sci 298, 1401–1410 (2020). https://doi.org/10.1007/s00396-020-04722-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04722-4