Abstract

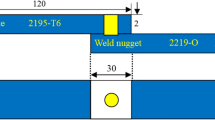

Due to different filling modes of the material in sleeve-affected zone (SAZ), probe-affected zone (PAZ), and thermo-mechanically affected zone (TMAZ), the micro-junction structure is formed at the bottom of the SAZ of the refill FSSW joint for 3.2-mm-thick 2060 aluminum alloys. The plasticized degree of the filling material and refilling time greatly affect the morphologies of micro-junction structure. Thus, the welding defects such as void with different sizes, kissing bond, and crack are easily formed in the micro-junction structure. Besides, the tensile-shear properties are related to the micro-junction structure and bonding strength of the lap interface. The increase of the plunge depth or rotation speed within a certain range enhances the flow of material in the stir zone and increases the atomic diffusion capacity of the lap interface, which is beneficial to increasing the tensile-shear load. The maximum tensile-shear load was obtained when the rotation speed of 2500 rpm and the plunge depth of 4 mm are used, and the tensile-shear specimen fractures along the bottom of the SAZ. Other fracture paths are also obtained under different welding parameters combinations, first along the lap interface, and second, not only along the lap interface but along the SAZ bottom.

Similar content being viewed by others

References

Chu Q, Li WY, Yang XW, Shen JJ, Li YB, Wang WB (2017) Study of process/structure/property relationships in probeless friction stir spot welded AA2198 Al-Li alloy. Weld World 61(2):291–298

Beaudoin AJ, Obstalecki M, Tayon W, Hernquist M, Mudrock R, Kenesei P, Lienert U (2013) In situ assessment of lattice strain in an Al-Li alloy. Acta Mater 61:3456–3464

Santana LM, Suhuddin UFH, Ölscher MH, Strohaecker TR, Santos JFD (2017) Process optimization and microstructure analysis in refill friction stir spot welding of 3-mm-thick Al-Mg-Si aluminum alloy. Int J Adv Manuf Tech 92:4213–4220

Vijayakumar P, Madhusudhanreddy G, Srinivasarao K (2015) Microstructure, mechanical and corrosion behavior of high strength AA7075 aluminium alloy friction stir welds-effect of post weld heat treatment. Def Technol 11:362–369

Lacki P, Derlatka A (2016) Experimental and numerical investigation of aluminium lap joints made by RFSSW. Meccanica 51:455–462

Chai P, Wang Y (2019) Effect of rotational speed on microstructure and mechanical properties of 2060 aluminum alloy RFSSW joint. Met Mater Int 25:1574–1585

Caroline DCC, Henrique PA, Guedes DAN, Fernandes DSJ (2018) Taguchi approach for the optimization of refill friction stir spot welding parameters for AA2198-T8 aluminum alloy. Int J Adv Manuf Tech 99:1927–1936

Tier MD, Rosendo TS, Santos JFD, Huber N, Strohaecker TR (2013) The influence of refill FSSW parameters on the microstructure and shear strength of 5042 aluminium welds. J Mater Process Tech 213:997–1005

Kluz R, Kubit A, Trzepiecinski T, Faes K (2019) Polyoptimisation of the refill friction stir spot welding parameters applied in joining 7075-t6 Alclad aluminium alloy sheets used in aircraft components. Int J Adv Manuf Tech 103:3443–3457

Adamus J, Adamus K (2019) The analysis of reasons for defects formation in aluminum joints created using RFSSW technology. Manuf lett 21:35–40

Zhao YQ, Liu HJ, Chen SX, Lin Z, Hou JC (2014) Effects of sleeve plunge depth on microstructures and mechanical properties of friction spot welded alclad 7B04-T74 aluminum alloy. Mater Des 62:40–46

Yang XW, Fu T, Li WY (2014) Friction stir spot welding: a review on joint macroand microstructure, property, and process modelling. Adv Mater Sci Eng 1:1–11

Wang Y, Chai P, Ma H, Cao XM, Zhang YH (2020) Formation mechanism and fracture behavior in extra-filling refill friction stir spot weld for Al-Cu-Mg aluminum alloy. J Mater Sci 55:358–374

Yue YM, Shi Y, Ji SD, Zhang LG, Wang Y (2017) Effect of sleeve plunge depth on microstructure and mechanical properties of refill friction stir spot welding of 2198 aluminum alloy. J Mater Eng Perform 26:5064–5071

Shen ZK, Yang XQ, Zhang ZH, Cui L, Li TL (2013) Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des 44:476–486

Shen ZK, Yang XQ, Yang S, Zhang ZH, Yin YH (2014) Microstructure and mechanical properties of friction spot welded 6061-T4 aluminum alloy. Mater Des 54:766–778

Shi Y, Yue YM, Zhang LG, Wang Y (2017) Refill friction stir spot welding of 2198-T8 aluminum alloy. T Indian I Metals 71:139–145

Oliveira PHF, Amancio-Filho ST, Dos Santos JF, Hage E Jr (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101

Li ZW, Ji SD, Ma YN, Chai P, Yue YM, Gao SS (2016) Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy. Int J Adv Manuf Technol 86:1925–1932

Zhao YQ, Wang CG, Dong CL, Deng J, Tan JH (2018) Numerical study on a thermal process in friction spot welding of Al-Zn-Mg-Cu alloy. Weld World 62:931–939

Cao JY, Wang M, Kong L, Yin YH, Guo LJ (2017) Numerical modeling and experimental investigation of 798 material flow in friction spot welding of Al 6061-T6. Int J Adv Manuf Technol 89:2129–2139

Kubit A, Bucior M, Wydrzyński D, Trzepieciński T, Pytel M (2018) Failure mechanisms of refill friction stir spot welded 7075-T6 aluminium alloy single-lap joints. Int J Adv Manuf Technol 94:4479–4491

Zhou L, Luo LY, Zhang TP, He WX, Feng JC (2017) Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy. Int J Adv Manuf Technol 92:3425–3433

Wang Y, Chai P. Characteristics and tensile-shear properties of refill FSSW joint under different plunge depths in 2060 aluminum alloy. Archives of Metallurgy and Materials, Accept

Acknowledgements

We appreciate that Beijing FSW Technology Co., Ltd provides the welding equipment for us. Meanwhile, thanks to AVIC Manufacturing Technology Institute for providing tensile-shear and metallographic experiments.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Yue Wang and Peng Chai. The first draft of the manuscript was written by Yue Wang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Wang, Y., Chai, P. Effects of welding parameters on micro-junction structure and fracture behavior of refill friction stir spot welded joints for 2060 aluminum alloys. Weld World 64, 2033–2051 (2020). https://doi.org/10.1007/s40194-020-00981-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00981-5