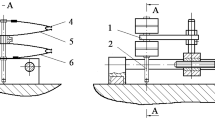

The procedure for the material damage assessment by the LM-hardness method, consisting of the in-service scratching of structure element surfaces and employing portable instruments for its implementation, is described. These instruments can provide the rapid analysis of damage of a structural element to be diagnosed, continuous measurement of axial displacements of the embedded scratching tip, moving over the surface of this element, systematization, and statistical processing of experimental data for Weibull homogeneity coefficient computations. The latter results derived via the LM-hardness method are used to assess the damage rate of the material. The advantage of these instruments is their high accuracy and performance in measuring a large number of axial displacements of the tip necessary for statistical processing as well as actual testing on vertical, ceiling, and inclined surfaces of structural elements.

Similar content being viewed by others

References

RD ÉO 0027-2005. Instructions for Determining the Mechanical Properties of the Equipment Metal of Nuclear Power Plants by Reference Sample Methods Based on Hardness Characteristics [in Russian], Rosénergoatom, Moscow, Introduced September 19, 2006.

M. P. Markovets, Hardness-Related Determination of Mechanical Properties of Materials [in Russian], Mashinostroenie, Moscow (1979).

N. A. Drozd, Nondestructive Testing of Mechanical Properties of the Metal [in Russian], Metallurgiya, Moscow (1965).

V. V. Kharchenko, O. A. Katok, and V. E. Filatov, “Assessment of strength characteristics of steels by instrumented indentation,” in: In-Service Damage of Materials, Its Diagnostics and Prediction Methods (Int. Sci.-Tech. Conf., September 21–24, 2009, Pulyuj Ternopil State Technical University), Ternopil (2009).

A. O. Lebedev and M. R. Muzyka, “Technical diagnostics of the material state by the LM-hardness method,” in: Problems of In-Service Life and Safety of Structures, Constructions, and Machines [in Ukrainian], Paton Institute of Electric Welding, National Academy of Sciences of Ukraine, Kyiv (2006).

DSTU ISO 6506-1:2007. Metallic Materials. Brinell Hardness Determination. Part 1. Test Method [in Ukrainian], Kyiv, Introduced January 1, 2009.

M. N. Khrushchev, Sclerometry [in Russian], Nauka, Moscow (1968).

A. Useinov and S. Useinov, “Measurement of mechanical properties by the scratching method,” Nanoindustriya, No. 6, 28–32 (2010).

V. N. Gadalov, Yu. V. Boldyrev, Yu. G. Alekhin, et al., “Studies on mechanical properties of protective coatings by the scratching method,” in: Design, Use, and Safety of Agricultural Equipment (Collection Sci. Works Conf.) [in Russian], Bryansk GSKhA, Bryansk (2004).

ASTM E2546-07. Standard Practice for Instrumented Indentation Testing, ASTM International, West Conshohocken, PA (2007).

GOST 21318-75. Microhardness Measurement by Diamond Tip Scratching [in Russian], Publishing House of Standards, Moscow (1978).

V. K. Grigorovich, Hardness and Microhardness of Metals [in Russian], Nauka, Moscow (1976).

V. M. Matyunin, On-Line Diagnostics of Mechanical Properties of Structural Materials [in Russian], Publishing House of MEI, Moscow (2006).

S. R. Ignatovich, I. M. Zakiev, and D. I. Borisov, “Assessment of the structural-deformation inhomogeneity of a thin surface layer of materials by the method of scratching,” Strength Mater., 40, No. 3, 334–342 (2008).

A. O. Lebedev, M. R. Muzyka, and N. L. Volchek, Assessment Method for the Material Degradation Due to In-Service Damage Accumulation, The LM-Hardness Method [in Ukrainian], Patent 52017 Ukraine, Valid since December 16, 2002.

V. F. Berdikov and V. V. Zav’yalov, “Unit for micromechanical studies by the indentation and scratching methods,” in: Novelties in Microhardness Testing [in Russian], Nauka, Moscow (1974), pp. 114–118.

A. A. Lebedev, N. R. Muzyka, and V. P. Shvets, “On options of improving reliability of material hardness assessment methods,” Strength Mater., 43, No. 3, 237–246 (2011).

ISO 14577-2:2002. Metallic Materials – Instrumented Indentation Test for Hardness and Materials Parameters – Part 2: Verification and Calibration of Testing Machines.

GOST 23677-79. Hardness Meters for Metals. General Specifications [in Russian], Publishing House of Standards, Moscow (1990).

GOST 2789-73. Surface Roughness. Parameters and Characteristics (with Modifications Nos. 1 and 2) [in Russian], Moscow, Introduced April 23, 1973.

E. V. Efymenko, M. R. Muzyka, V. P. Shvets, and A. O. Lebedev, Instrument for Hardness Testing of the Material by Scratching [in Ukrainian], Patent 62014 Ukraine, Valid since August 10, 2011.

V. V. Kharchenko, M. R. Muzyka, V. P. Lamashevskii, et al., Portable Instrument for Sclerometric Studies [in Ukrainian], Patent 115815 Ukraine, Valid since April 25, 2017.

DSTU GOST 9031:2009. Reference Hardness Measures. Specifications [in Ukrainian], Introduced February 1, 2009.

DSTU GOST 8.207:2008. Interstate Standard. State System of Maintenance of Unified Measurements. Direct Measurements with Multiple Observations. Methods of Processing of Observation Results. Basic Provisions [in Russian], Introduced June 25, 2008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 3, pp. 115 – 124, May – June, 2020.

Rights and permissions

About this article

Cite this article

Muzyka, N.R., Shvets, V.P. & Boiko, A.V. Procedure and Instruments for the Material Damage Assessment by the LM-Hardness Method on the In-Service Scratching of Structure Element Surfaces. Strength Mater 52, 432–439 (2020). https://doi.org/10.1007/s11223-020-00195-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00195-6