Abstract

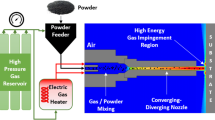

A hybrid analytical heat conduction model was developed to predict the transient thermal evolution at the particle–substrate interface during the deposition of cold spray process. First, three-dimensional heat conduction model based on classical diffusion approach was developed to predict the transient surface temperature of the substrate. To that end, the traveling wave solution technique was utilized in order to take into account the effect of the movement of the cold spray nozzle. The results of the analytical model were validated with the experimentally measured surface temperature which was obtained by employing a low-pressure cold spray unit to generate the impingement of a compressed air jet on a flat substrate. The analytical model was further utilized to investigate the effect of the non-dimensional characteristic velocity of the traveling heat source on the surface temperature profile of the substrate. It was found that both the maximum surface temperature and the spatial variation of surface temperature profile of the substrate decreased as the non-dimensional characteristic velocity increased. The mathematical model was further extended by developing a one-dimensional hyperbolic (non-Fourier) heat conduction model to predict the temperature rise at the particle–substrate interface during the cold spray deposition process. In order to validate the results of the hybrid model, a three-dimensional finite element model was developed in ABAQUS to simulate the thermal and dynamic behavior of a single particle upon impact. The results of the hybrid analytical model for the temperature at the particle–substrate interface were compared to the results of the numerical model, and good agreement was found. It was concluded that by coupling the classical diffusion theory and hyperbolic heat conduction approach, the proposed hybrid analytical model can be utilized to predict the transient temperature of the particle–substrate interface during the cold spray deposition process a priori before experimentation.

Similar content being viewed by others

Abbreviations

- A :

-

Arbitrary constant

- b :

-

Half of the substrate width (m)

- B :

-

Arbitrary constant

- c :

-

Heat wave speed (m/s)

- C :

-

Arbitrary constant

- C p :

-

Heat capacity (J/K)

- d :

-

Particle diameter (m)

- dt :

-

Time interval (s)

- D :

-

Cold spray nozzle diameter (m)

- E :

-

Relative error

- EK:

-

Kinetic energy (J)

- f :

-

Arbitrary continuous function

- h :

-

Heat transfer coefficient (W/m2 K)

- k :

-

Thermal conductivity (W/m K)

- l :

-

Substrate length (m)

- m :

-

Mass (kg)

- M :

-

Discretized sampling point

- N :

-

Norm of the differential equation

- q′′:

-

Heat flux (W/m2)

- r :

-

Radial coordinate

- s :

-

Kinetic energy conversion factor

- S :

-

Average contact surface (m2)

- SOD:

-

Stand-off distance (m)

- t :

-

Time (s)

- T :

-

Temperature (°C)

- T 0 :

-

Substrate initial temperature (°C)

- u :

-

Nozzle velocity (m2/s)

- V :

-

Velocity (m/s)

- x :

-

x-coordinate

- x′:

-

Dummy variable in x-coordinate (m)

- y :

-

y-coordinate

- y′ :

-

Dummy variable in y-coordinate (m)

- z :

-

z-coordinate

- z′:

-

Dummy variable in z-coordinate (m)

- Fo:

-

Fourier number \({\text{Fo}} = \frac{{\alpha_{\text{s}} t}}{{\delta^{2} }}\)

- Nu:

-

Nusselt number \({\text{Nu}} = \frac{{hD_{\text{n}} }}{{k_{\text{g}} }}\)

- Stk:

-

Stokes number \({\text{Stk}} = \kappa_{\text{p}} \frac{{u_{\text{g}} }}{{D_{\text{n}} }}\)

- α :

-

Thermal diffusivity (m2/s)

- β :

-

Eigenvalues in y-coordinate

- γ :

-

Eigenvalues in z-coordinate

- δ :

-

Thickness of the substrate (m)

- ε :

-

Plastic strain

- \(\dot{\varepsilon }\) :

-

Plastic strain rate

- η :

-

Non-dimensional radius

- θ :

-

Non-dimensional temperature

- κ :

-

Momentum characteristic velocity (m2/s)

- λ :

-

Eigenvalues in x-coordinate

- µ :

-

Dynamic viscosity (kg/m s)

- ξ :

-

Dummy variable in x-coordinate

- ρ :

-

Density (kg/m3)

- ς :

-

Relaxation time (s)

- σ :

-

Flow stress (MPa)

- τ :

-

Time dummy variable (s)

- ψ :

-

Non-dimensional stand-off distance

- ϑ :

-

Non-dimensional characteristic velocity

- AW:

-

Adiabatic wall

- Exp:

-

Experimental

- g:

-

Propellant gas

- i:

-

Numerator in x-coordinate

- j:

-

Numerator in y-coordinate

- l:

-

Melting temperature index

- m:

-

Numerator in z-coordinate

- n:

-

Nozzle

- p:

-

Particle

- r:

-

Reference temperature index

- s:

-

Substrate/surface

- ∞:

-

Ambient

References

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V. Fomin, Cold Spray Technology, 1st ed., Elsevier, Amsterdam, 2007

P. Sirvent, M. Garrido, C. Múnez, P. Poza, and S. Vezzù, Effect of Higher Deposition Temperatures on the Microstructure and Mechanical Properties of Al 2024 Cold Sprayed Coatings, Surf. Coat. Technol., 2018, 337, p 461-470

Y. Xie, M. Planche, R. Raoelison, P. Hervé, X. Suo, P. He, and H. Liao, Investigation on the Influence of Particle Preheating Temperature on Bonding of Cold-Sprayed Nickel Coatings, Surf. Coat. Technol., 2017, 318, p 99-105

Y. Watanabe, C. Yoshida, K. Atsumi, M. Yamada, and M. Fukumoto, Influence of Substrate Temperature on Adhesion Strength of Cold-Sprayed Coatings, J. Therm. Spray Technol., 2015, 24(1–2), p 86-91

M. Fukumoto, H. Wada, K. Tanabe, M. Yamada, E. Yamaguchi, A. Niwa, M. Sugimoto, and M. Izawa, Effect of Substrate Temperature on Deposition Behavior of Copper Particles on Substrate Surface in the Cold Spray Process, J. Therm. Spray Technol., 2007, 16(5–6), p 643-650

J. Legoux, E. Irissou, and C. Moreau, Effect of Substrate Temperature on the Formation Mechanism of Cold-Sprayed Aluminum, Zinc and Tin Coatings, J. Therm. Spray Technol., 2007, 16(5–6), p 619-626

C. Chen, Y. Xie, C. Verdy, R. Huang, H. Liao, Z. Ren, and S. Deng, Numerical Investigation of Transient Coating Build-Up and Heat Transfer in Cold Spray, Surf. Coat. Technol., 2017, 326, p 355-365

T. Schmidt, H. Assadi, F. Gartner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18, p 794-808

A. Mahdavi and A. McDonald, Analytical Study of the Heat Transfer Coefficient of the Impinging Air Jet During Cold Spraying, Int. J. Therm. Sci., 2018, 130, p 289-297

A. Mahdavi and A. McDonald, Effect of Substrate and Process Parameters on the Gas-Substrate Convective Heat Transfer Coefficient During Cold Spraying, J. Therm. Spray Technol., 2018, 27(3), p 433-445

A. Ryabinin, E. Irissou, A. McDonald, and J.-G. Legoux, Simulation of Gas-Substrate Heat Exchange During Cold-Gas Dynamic Spraying, Int. J. Therm. Sci., 2012, 56, p 12-18

B. Samareh and A. Dolatabadi, A Three-Dimensional Analysis of the Cold Spray Process: The Effects of Substrate Location and Shape, J. Therm. Spray Technol., 2007, 16, p 634-642

D. Rosenthal, Mathematical Theory of Heat Distribution During Welding and Cutting, Weld. J., 1941, 20(5), p 220-234

C.-K. Kim, An Analytical Solution to Heat Conduction with a Moving Heat Source, J. Mech. Sci. Technol., 2011, 25(4), p 895-899

M. Song and R. Kovacevic, Thermal Modeling of Friction Stir Welding in a Moving Coordinate System and Its Validation, Int. J. Mach. Tools Manuf, 2003, 43, p 605-615

N. Al-Huniti, Dynamic Response to a Rod Due to a Moving Heat Source Under the Hyperbolic Heat Condition Model, J. Sound Vib., 2001, 242(2), p 629-640

O. Manca, B. Morrone, and V. Naso, Quasi-Steady-State Three-Dimensional Temperature Distribution Induced by a Moving Circular Gaussian Heat Source in a Finite Depth Solid, Int. J. Heat Mass Transf., 1995, 38(7), p 1305-1315

A. McDonald, A. Ryabinin, E. Irissou, and J.-G. Legoux, Gas-Substrate Heat Exchange During Cold-Gas Dynamic Spraying, J. Therm. Spray Technol., 2013, 22(2–3), p 391-397

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

M. Grujicic, C. Zhao, W. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic Spray Process, Mater. Des., 2004, 25, p 681-688

W. Li, C. Zhang, X. Guo, C. Li, H. Liao, and C. Coddet, Study on Impact Fusion at Particle Interfaces and Its Effect on Coating Microstructure in Cold Spraying, Appl. Surf. Sci., 2007, 254, p 517-526

S. Guetta, M. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, Y. Ichikawa, K. Sakaguchi, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18, p 331-342

M. Hassani-Gangaraj, D. Veysset, V. Champagne, K. Nelson, and C. Schuh, Adiabatic Shear Instability is Not Necessary for Adhesion in Cold Spray”, Acta Mater., 2018, 158, p 430-439

M. Grujicic, J. Saylor, D. Beasley, A.W. Derosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 19, p 211-227

G. Bae, S. Kumar, S. Yoon, M. Kang, H. Na, H. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666

M. Hassani-Gangaraj, D. Veysset, K. Nelson, and C. Schuh, In-Situ Observations of Single Micro-particle Impact Bonding, Scr. Mater., 2018, 145, p 9-13

L. Liu, H. Tan, and T. Tong, Non-Fourier Effects on Transient Temperature Response in Semitransparent Medium Caused by Laser Pulse, Int. J. Heat Mass Transf., 2001, 44(17), p 3335-3344

W.B. Lor and H.S. Chu, Effect of Interface Thermal Resistance on Heat Transfer in a Composite Medium Using the Thermal Wave Model, Int. J. Heat Mass Transf., 2000, 43(5), p 653-663

C. Cattaneo, A Form of Heat-Conduction Equations Which Eliminates the Paradox of Instantaneous Propagation, C. R., 1958, 247, p 431

P. Vernotte, Some Possible Complications in the Phenomena of Thermal Conduction, C. R., 1961, 252, p 2190

M.H. Babaei and Z. Chen, Transient Hyperbolic Heat Conduction in a Functionally Graded Hollow Cylinder, J. Thermophys. Heat Transf., 2010, 24(2), p 325-330

A. Pourasghar and Z. Chen, Hyperbolic Heat Conduction and Thermoelastic Solution of Functionally Graded CNT Reinforced Cylindrical Panel Subjected to Heat Pulse, Int. J. Solids Struct., 2019, 163, p 117-129

A. Pourasghar and Z. Chen, Dual-Phase-Lag Heat Conduction in fg Carbon Nanotube Reinforced Polymer Composites, Phys. B, 2019, 564, p 147-156

A. Pourasghar and Z. Chen, Dual-Phase-Lag Heat Conduction in the Composites by Introducing a New Application of DQM, Heat Mass Transf., 2020, 56, p 1171-1177

A. Volpert, V. Volpert, and V. Volpert, Traveling Wave Solutions of Parabolic Systems, Translation of mathematical Monographs, Vol 140, American Mathematical Society, Rhode Island, 1994, p 1-32

M. Özişik, Heat Conduction, 2nd ed., Wiley, New York, 1993

C. Shu, Q. Yao, and K. Yao, Block-Marching in Time with DQ Discretization: An Efficient Method for time-Dependent Problems, Comput. Methods Appl. Mech., 2002, 191, p 4587-4597

A. Pourasghar and S. Kamarian, Three-Dimensional Solution for the Vibration Analysis of Functionally Graded Multiwalled Carbon Nanotubes/Phenolic Nanocomposite Cylindrical Panels on Elastic Foundation, Polym. Compos., 2013, 34(12), p 2040-2048

C.A. Dorao, Simulation of Thermal Disturbances with Finite Wave Speeds Using a High Order Method, J. Comput. Appl. Math., 2009, 231, p 637-647

R. Kapoor and S. Nemat-Nasser, Determination of Temperature Rise During High Strain Rate Deformation, Mech. Mater., 1998, 27(1), p 1-12

Abaqus Analysis User’s Manual, Version 6.13.

Q. Chen, A. Alizadeh, W. Xie, X. Wang, V. Champagne, A. Gouldstone, J. Lee, and S. Muftu, High-Strain-Rate Material Behavior and Adiabatic Material Instability in Impact of Micron-Scale Al-6061 Particles, J. Therm. Spray Technol., 2018, 27, p 641-653

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

C. Donaldson and R. Snedeker, A Study of Free Jet Impingement. Part 1. Mean Properties of Free and Impinging Jets, J. Fluid Mech., 1971, 45, p 281-319

C.T. Crowe, Mutiphase Flow Handbook, Taylor & Francis Group, New York, 2006

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5–6), p 794-808

C. Rogers and J. Eaton, The Effect of Small Particles on Fluid Turbulence in a Flat-Plate, Turbulent Boundary Layer in Air, Phys. Fluids A Fluid, 1991, 3(5), p 928-937

A. Shapiro, The Dynamics and Thermodynamics of Compressible Fluid Flow, Vol II, The Ronald Press Company, New York, 1954

D. Kim, J. Park, J. Lee, D. Kim, S. Tark, S. Ahn, J. Yun, J. Gwak, K. Yoon, S. Chandra, and S. Yoon, Cold Spray Deposition of Copper Electrodes on Silicon and Glass Substrates, J. Therm. Spray Technol., 2013, 22(7), p 1092-1102

G. Wei, P. Huang, C. Xu, D. Liu, X. Ju, X. Du, L. Xing, and Y. Tang, Thermophysical Property Measurements and Thermal Energy Storage Capacity Analysis of Aluminum Alloys, Sol. Energy, 2016, 137, p 66-72

J. Gilbert Kaufman, Fire Resistance of Aluminum and Aluminum Alloys and Measuring the Effects of Fire Exposure on the Properties of Aluminum Alloys, Chapter 1: Properties and Characteristics of Aluminum and Aluminum Alloys, ASM International, Cleveland, 2016

J. Pattison, S. Celotto, A. Khan, and W. O’Neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surf. Coat. Technol., 2008, 202(8), p 1443-1454

P. King, G. Bae, S. Zahiri, M. Jahedi, and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2009, 19, p 620-634

P. King, S. Zahiri, and M. Jahedi, Focused Ion Beam Micro-dissection of Cold Sprayed Particles, Acta Mater., 2008, 56(19), p 5617-5626

S. Guetta, M. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, Y. Ichikawa, K. Sakaguchi, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18(3), p 331-342

S. Barradas, V. Guipont, R. Molins, M. Jeandin, M. Arrigoni, M. Boustie, C. Bolis, L. Berthe, and M. Ducos, Laser Shock Flier Impact Simulation of Particle-Substrate Interactions in Cold Spray, J. Therm. Spray Technol., 2007, 16(4), p 475-479

Y.L. Yao, H. Chen, and W. Zhang, Time Scale Effects in Laser Material Removal: A Review, Int. J. Manuf. Technol., 2005, 26, p 598-608

M. Xu, J. Guo, L. Wang, and L. Cheng, Thermal Wave Interference as the Origin of the Overshooting Phenomenon in Dual-Phase-Lagging Heat Conduction, Int. J. Therm. Sci., 2011, 50(5), p 825-830

M. Al-Nimr and M. Alkam, Overshooting Phenomenon in the Hyperbolic Microscopic Heat Conduction Model, Int. J. Thermophys., 2003, 24(2), p 577-583

R. Lupoi and W. O’neill, Deposition of Metallic Coatings on Polymer Surfaces Using Cold Spray, Surf. Coat. Technol., 2010, 205(7), p 2167-2173

M. Hassani-Gangaraj, D. Veysset, K. Nelson, and C. Schuh, Melt-Driven Erosion in Microparticle Impact, Nat. Commun., 2018, 9, p 5077

Acknowledgments

Portions of this paper have been published in A. Mahdavi, A. McDonald, “Determination of the temperature distribution of a substrate exposed to a moving cold or thermal spray heat source”, in: International Thermal Spray Conference, May 7-10, 2018 (Orlando, FL, USA), ASM International, (2018), #44653; A. Mahdavi, A. Pourasghar, Z. Chen, A. McDonald, “Transient Thermal Evolution during Deposition of Cold-sprayed Coatings”, in: International Thermal Spray Conference, May 25-29, 2019 (Yokohama, Japan), ASM International, (2019), # 46993; and A. Mahdavi, A. McDonald, “Heat Transfer Coefficient of an Under-Expanding Cold Spray Air Jet on a Flat Substrate”, in: Proceedings of the 5th International Conference of Fluid Flow, Heat and Mass Transfer (FFHMT'18), June 7-9, 2018 (Niagara Falls, ON, Canada), #170. Funding for this project was provided by the Natural Science and Engineering Research Council of Canada on a Discovery Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

A boundary condition of the third kind (Robin condition), including the effects of radiation from the substrate, was supposed to be applied at the front surface of the substrate (at z = 0) to model the heat flux due to impinging jet (Eq 6 in the manuscript).

The second term on the right-hand side of abovementioned equation represents the heat loss from the front surface by radiation to the ambient at temperature, T∞. It has been reported that if the relative temperature difference between the substrate and the ambient, \(\frac{{\left| {T - T_{\infty } } \right|}}{{T{}_{\infty }}}\), is on the order of one or less, the radiation term in Eq 2-4 can be linearized and reformulated as (Ref 34)

where hrad is the radiative heat transfer coefficient and is defined as (Ref 34)

where ε is the emissivity of the substrate and it was assumed to be 0.96, and σ is the Stefan–Boltzmann constant (σ = 5.67 × 10−8 W/m2 K4). According to the experimental results previous studies study (Ref 9, 10), the relative temperature difference between the substrate and the ambient was measured to be on the order of one. Therefore, the aforementioned assumption of linearization of the radiation term was valid and it can be expressed as

By applying a scale analysis on the radiation term in the above-mentioned equation, it can be deduced that the radiation effects on the temperature distribution within the substrate were negligible. In other words, by incorporating the approximate values of each term in this equation, and considering T∞ = 21 °C (294 K), the radiative heat transfer coefficient will be on the order of one, while the convective heat transfer coefficient of an impinging air jet is expected to be on the order of 102 (Ref 9). In light of the aforementioned scale analysis and in order to simplify the problem, the effects of radiation were not considered in the mathematical modeling. Therefore, the boundary condition was reformulated as

Regarding the accuracy of the FLIR measurements, a detailed error analysis was conducted in a previous study (Ref 9) in order to predict the uncertainty propagation in the results of the developed semi-empirical analytical model. Please note that the emissivity of substrate which was used in the scale analysis was identical to that in the experimental measurements.

Rights and permissions

About this article

Cite this article

Mahdavi, A., Pourasghar, A., Chen, Z. et al. Particle–Substrate Transient Thermal Evolution During Cold Spray Deposition Process: A Hybrid Heat Conduction Analysis. J Therm Spray Tech 29, 1609–1627 (2020). https://doi.org/10.1007/s11666-020-01084-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01084-9