Abstract

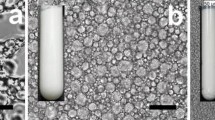

PolyHIPEs are an important class of porous polymers with well-defined hierarchical porosity and tunable morphology. However, the insufficient mechanical properties arise due to high volume of voids bringing difficulties in applications. In this study, polyHIPEs with tailored morphological and mechanical properties were prepared by using a monoterpene for the first time. In this respect, copolymerization of β-myrcene with several comonomers within water-in-oil (w/o) high internal phase emulsions (HIPEs) has been extensively investigated. Accordingly, combining β-myrcene and ethylene glycol dimethacrylate (EGDMA) in polyHIPE structure was demonstrated as a successful approach for tailoring the morphology, as well as the mechanical strength. PolyHIPEs with cavities between 1.09 and 3.55 μm were obtained by changing the ratio of β-myrcene in the continuous phase of HIPEs. Moreover, resulting polyHIPEs have found to have improved mechanical strength. The highest compressive modulus achieved for the obtained monoliths was determined to be 38.8 MPa.

Graphical abstract

Similar content being viewed by others

References

Silverstein MS (2020) The chemistry of porous polymers: the holey grail. Isr J Chem 60:1–12. https://doi.org/10.1002/ijch.202000003

Zhang T, Sanguramath RA, Israel S, Silverstein MS (2019) Emulsion templating: porous polymers and beyond. Macromolecules 52:5445–5479. https://doi.org/10.1021/acs.macromol.8b02576

Zhang T, Zhao Y, Silverstein MS (2020) Cellulose-based, highly porous polyurethanes templated within non-aqueous high internal phase emulsions. Cellulose 27:4007–4018. https://doi.org/10.1007/s10570-020-03059-z

David D, Silverstein MS (2009) Porous polyurethanes synthesized within high internal phase emulsions. J Polym Sci A Polym Chem 47:5806–5814. https://doi.org/10.1002/pola.23624

Naranda J, Sušec M, Maver U, Gradišnik L, Gorenjak M, Vukasović A, Ivković A, Rupnik MS, Vogrin M, Krajnc P (2016) Polyester type polyHIPE scaffolds with an interconnected porous structure for cartilage regeneration. Sci Rep 6:28695. https://doi.org/10.1038/srep28695

Gurevitch I, Silverstein MS (2011) Nanoparticle-based and organic-phase-based AGET ATRP polyHIPE synthesis within Pickering HIPEs and surfactant-stabilized HIPEs. Macromolecules 44:3398–3409. https://doi.org/10.1021/ma200362u

Khodabandeh A, Dario Arrua R, Desire CT, Rodemann T, Bon SAF, Thickett SC, Hilder EF (2016) Preparation of inverse polymerized high internal phase emulsions using an amphiphilic macro-RAFT agent as sole stabilizer. Polym Chem 7:1803–1812. https://doi.org/10.1039/C5PY02012C

Mert EH, Slugovc C, Krajnc P (2015) Tailoring the mechanical and thermal properties of dicyclopentadiene polyHIPEs with the use of a comonomer. eXPRESS Polym Lett 9:344–353. https://doi.org/10.3144/expresspolymlett.2015.32

Yüce E, Mert EH, Krajnc P, Parın FN, San N, Kaya D, Yıldırım H (2017) Photocatalytic activity of titania/polydicyclopentadiene polyHIPE composites. Macromol Mater Eng 302:1700091. https://doi.org/10.1002/mame.201700091

Pulko I, Krajnc P (2017) Porous polymer monoliths by emulsion templating. Encyclopedia of Polymer Science and Technology, Wiley. https://doi.org/10.1002/0471440264.pst653

Barby D, Haq Z (1982) Low density porous cross-linked polymeric materials and their preparation. Eur Patent 0060138

Cameron NR (2005) High internal phase emulsion templating as a route to well-defined porous polymers. Polymer 46:1439–1449. https://doi.org/10.1016/j.polymer.2004.11.097

Mert HH, Mert MS, Mert EH (2019) A statistical approach for tailoring the morphological and mechanical properties of polystyrene polyHIPEs: looking through experimental design. Mater Res Express 6:1153006. https://doi.org/10.1088/2053-1591/ab437f

Yüce E, Parın FN, Krajnc P, Mert HH, Mert EH (2018) Influence of titania on the morphological and mechanical properties of 1,3-butanediol dimethacrylate based polyHIPE composites. React Func Polym 130:8–15. https://doi.org/10.1016/j.reactfunctpolym.2018.05.009

Paljevac M, Kotek J, Jeřabek K, Krajnc P (2018) Influence of topology of highly porous methacrylate polymers on their mechanical properties. Macromol Mater Eng 303:1700337. https://doi.org/10.1002/mame.201700337

Menner A, Salgueiro M, Shaffer MSP, Bismarck A (2008) Nanocomposite foams obtained by polymerization of high internal phase emulsions. J Polym Sci Part A Polym Chem 46:5708–5714. https://doi.org/10.1002/pola.22878

Yüce E, Krajnc P, Mert HH, Mert EH (2019) Influence of nanoparticles and antioxidants on mechanical properties of titania/polydicyclopentadiene polyHIPEs: a statistical approach. J Appl Polym Sci 136:46913. https://doi.org/10.1002/app.46913

Berber E, Çira F, Mert EH (2016) Preparation of porous polyester composites via emulsion templating: investigation of the morphological, mechanical, and thermal properties. Polym Compos 37:1531–1538. https://doi.org/10.1002/pc.23323

Wu R, Menner A, Bismarck A (2010) Tough interconnected polymerized medium and high internal phase emulsions reinforced by silica particles. J Polym Sci Part A Polym Chem 48:1979–1989. https://doi.org/10.1002/pola.23965

Çira F, Mert EH (2015) PolyHIPE/Pullulan composites derived from glycidyl methacrylate and 1,3-butanediol dimethacrylate-based high internal phase emulsions. Polym Eng Sci 55:2636–2642. https://doi.org/10.1002/pen.24156

Huš S, Kolar M, Krajnc P (2015) Tailoring morphological features of cross-linked emulsion-templated poly(glycidyl methacrylate). Des Monomers Polym 18:698–703. https://doi.org/10.1080/15685551.2015.1070503

Huš S, Krajnc P (2015) PolyHIPEs from methyl methacrylate: hierarchically structured microcellular polymers with exceptional mechanical properties. Polymer 55:4420–4424. https://doi.org/10.1016/j.polymer.2014.07.007

Kovačič S, Matsko NB, Ferk G, Slugovc C (2013) Macroporous poly(dicyclopentadiene) γFe2O3/Fe3O4 nanocomposite foams by high internal phase emulsion templating. J Mater Chem A 1:7971–7978. https://doi.org/10.1039/C3TA11402C

Vakalopoulou E, Slugovc C (2019) The effects of enhancing the crosslinking degree in high internal phase emulsion templated poly(dicyclopentadiene) cured by ring-opening metathesis polymerization by a crosslinking comonomer. Macromol Chem Phys 220:1900423. https://doi.org/10.1002/macp.201900423

Bauer N, Brunke J, Kali G (2017) Controlled radical polymerization of myrcene in bulk: mapping the effect of conditions on the system. ACS Sustain Chem Eng 5:10084–10092. https://doi.org/10.1021/acssuschemeng.7b02091

Behr A, Johnen L (2009) Myrcene as a natural base chemical in sustainable chemistry: a critical review. Chem Sus Chem 2:1072–1095. https://doi.org/10.1002/cssc.200900186

Métafiot A, Kanawati Y, Gérard JF, Defoort B, Marić M (2017) Synthesis of β-myrcene-based polymers and styrene block and statistical copolymers by SG1 nitroxide-mediated controlled radical polymerization. Macromolecules 50:3101–3120. https://doi.org/10.1021/acs.macromol.6b02675

Yang X, Li S, Xia J, Song J, Huang K, Li M (2015) Renewable myrcene-based-UV-curable monomer and its copolymers with acrylated epoxidized soybean oil: design, preparation, and characterization. Bioresources 10:2130–2142. https://doi.org/10.15376/biores.10.2.2130-2142

Johanson AJ, Mckennon FL, Goldblatt LA (1948) Emulsion polymerization of myrcene. Ind Eng Chem 40:500–502. https://doi.org/10.1021/ie50459a033

Loughmari S, Hafid A, Bouazza A, El Bouadili A, Zinck P, Visseaux M (2012) Highly stereoselective coordination polymerization of β-myrcene from a lanthanide-based catalyst: access to bio-sourced elastomers. J Polym Sci Part A Polym Chem 50:2898–2905. https://doi.org/10.1002/pola.26069

Metafiot A, Gérard JF, Defoort B, Marić M (2018) Synthesis of β-myrcene/glycidyl methacrylate statistical and amphiphilic diblock copolymers by SG1 nitroxide-mediated controlled radical polymerization. J Polym Sci Part A Polym Chem 56:860–878. https://doi.org/10.1002/pola.28963

Hilschmann J, Kali G (2015) Bio-based polymyrcene with highly ordered structure via solvent free controlled radical polymerization. Eur Polym J 73:363–373. https://doi.org/10.1016/j.eurpolymj.2015.10.021

Cawse JL, Stanford JL, Still RH (1986) Polymers from renewable sources. III. Hydroxy-terminated myrcene polymers. J Appl Polym Sci 31:1963–1975. https://doi.org/10.1002/app.1986.070310702

Cawse JL, Stanford JL, Still RH (1986) Polymers from renewable sources. IV. Polyurethane elastomers based on myrcene polyols. J Appl Polym Sci 31:1549–1565. https://doi.org/10.1002/app.1986.070310602

Cawse JL, Stanford JL, Still RH (1987) Polymers from renewable sources: 5. Myrcene-based polyols as rubber-toughening agents in glassy polyurethanes. Polymer 28:368–374. https://doi.org/10.1016/0032-3861(87)90187-X

Still RH, Cawse JL, Stanford J (1984) Functionally Terminated Polymers from Terpene Monomers and Their Applications. US Patent 4564718

Barbetta A, Cameron NR (2004) Morphology and surface area of emulsion-derived (polyHIPE) solid foams prepared with oil-phase soluble porogenic solvents: span 80 as surfactant. Macromolecules 37:3188–3201. https://doi.org/10.1021/ma0359436

Trumbo DL (1993) Free radical copolymerization behavior of myrcene I. copolymers with styrene, methyl methecrylate or p-fluorostyrene. Polym Bull 31:629–636. https://doi.org/10.1007/BF00300120

Matic A, Schlaad H (2018) Thiol-ene photofunctionalization of 1,4-polymyrcene. Polym Int 67:500–505. https://doi.org/10.1002/pi.5534

Krajnc P, Lebera N, Štefanec D, Kontrec S, Podgornik A (2005) Preparation and characterisation of poly(high internal phase emulsion) methacrylate monoliths and their application as separation media. J Chrom A 1065:69–73. https://doi.org/10.1016/j.chroma.2004.10.051

Barbetta A, Dentini M, Leandri L, Ferraris G, Coletta A, Bernabei M (2009) Synthesis and characterization of porous glycidyl methacrylate–divinylbenzene monoliths using the high internal phase emulsion approach. React Funct Polym 69:724–736. https://doi.org/10.1016/j.reactfunctpolym.2009.05.007

Vlakh EG, Tennikova TB (2007) Preparation of methacrylate monoliths. J Sep Sci 30:2801–2813. https://doi.org/10.1002/jssc.200700284

Peters EC, Svec F, Fréchet JMJ (1997) Preparation of large-diameter “molded” porous polymer monoliths and the control of pore structure homogeneity. Chem Mater 9:1898–1902. https://doi.org/10.1021/cm970204n

Strancar A, Podgornik A, Barut M, Necina R (2002) Short monolithic columns as stationary phases for chromatography. In: Scheper T (ed) Advances in Biochemical Engineering & Biotechnology 76. Springer-Verlag, Berlin-Heidelberg, pp 49–85

Luo Y, Wang AN, Gao X (2015) One-pot interfacial polymerization to prepare polyHIPEs with functional surface. Colloid Polym Sci 293:1767–1779. https://doi.org/10.1007/s00396-015-3567-y

Robinson JL, Moglia RS, Stuebben MC, McEnery MAP, Cosgriff-Hernandez E (2014) Achieving interconnected pore architecture in injectable polyHIPEs for bone tissue engineering. Tissue Eng Part A 20:1103–11012. https://doi.org/10.1089/ten.tea.2013.0319

Quell A, Bergolis B, Drenckhan W, Stubenrauch C (2016) How the locus of initiation influences the morphology and the pore connectivity of a monodisperse polymer foam. Macromolecules 49:5059–5067. https://doi.org/10.1021/acs.macromol.6b00494

Stubenrauch C, Menner A, Bismarck A, Drenckhan W (2018) Emulsion and foam templating—promising routes to tailor-made porous polymers. Angew Chem Int Ed 57:10024–10032. https://doi.org/10.1002/anie.201801466

Rezanavaz R, Fee CJ, Dimartino S (2018) GMA-based emulsion-templated solid foams: influence of co-crosslinker on morphology and mechanical properties. J Appl Polym Sci 135:46295. https://doi.org/10.1002/APP.46295

Wu R, Menner A, Bismarck A (2013) Macroporous polymers made from medium internal phase emulsion templates: effect of emulsion formulation on the pore structure of polyMIPEs. Polymer 54:5511–5517. https://doi.org/10.1016/j.polymer.2013.08.029

Acknowledgments

Authors thank the MG International Fragrance Company, Gülçiçek Kimya (Gebze, Kocaeli, Turkey), for their kind donation of β-myrcene.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mert, E.H., Kekevi, B. Synthesis of polyHIPEs through high internal phase emulsions of β-myrcene. Colloid Polym Sci 298, 1423–1432 (2020). https://doi.org/10.1007/s00396-020-04730-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04730-4