Abstract

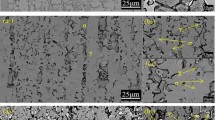

The effect of microstructure and passive film on the corrosion resistance of 2507 super duplex stainless steel (SDSS) in simulated marine environment was investigated by electrochemical measurements, periodic wet-dry cyclic corrosion test, scanning Kelvin probe force microscopy, atomic force microscopy, and X-ray photoelectron spectrometry. The results show that the occupation ratio of γ phase increases with the decrease in cooling rate, whereas the content of α phase reduces gradually. In addition, the σ precipitated phase only emerges in the annealed steel. The pitting sensitivity and corrosion rate of 2507 SDSS reduce first and then increase as the cooling rate decreases. The σ precipitated phase drastically reduces the protective ability of the passive film and facilitates micro-galvanic corrosion of the annealed steel. For various microstructures, the pits are preferentially distributed within the σ and γ phases. The corrosion resistance of 2507 SDSS prepared by different cooling methods is closely related to the microstructure and structure (stability and homogeneity) of the passive film. Normalized steel shows an optimal corrosion resistance, followed by the quenched and annealed steels.

Similar content being viewed by others

References

X. Zhang, W.Z. Wei, L. Cheng, J. Liu, K.M. Wu, and M. Liu, Effects of niobium and rare earth elements on microstructure and initial marine corrosion behavior of low-alloy steels, Appl. Surf. Sci., 475(2019), p. 83.

H.C. Ma, Y. Fan, Z.Y. Liu, C.W. Du, and X.G. Li, Effect of pre-strain on the electrochemical and stress corrosion cracking behavior of E690 steel in simulated marine atmosphere, Ocean Eng., 182(2019), p. 188.

M. Cao, L. Liu, Z.F. Yu, L. Fan, and F.H. Wang, Electrochemical corrosion behavior of 2A02 Al alloy under an accelerated simulation marine atmospheric environment, J. Mater. Sci. Technol., 35(2019), No. 4, p. 651.

Z.Y. Liu, W.K. Hao, W. Wu, H. Luo, and X.G. Li, Fundamental investigation of stress corrosion cracking of E690 steel in simulated marine thin electrolyte layer, Corros. Sci., 148(2019), p. 388.

C.Q. Cheng, L.I. Klinkenberg, Y. Ise, J. Zhao, E. Tada, and A. Nishikata, Pitting corrosion of sensitised type 304 stainless steel under wet-dry cycling condition, Corros. Sci., 118(2017), p. 217.

N.W. Dai, Q.M. Chen, J.X. Zhang, X. Zhang, Q.Z. Ni, Y.M. Jiang, and J. Li, The corrosion behavior of steel exposed to a DC electric field in the simulated wet-dry cyclic environment, Mater. Chem. Phys., 192(2017), p. 190.

X. Zhang, S.W. Yang, W.H. Zhang, H. Guo, and X.L. He, Influence of outer rust layers on corrosion of carbon steel and weathering steel during wet-dry cycles, Corros. Sci., 82(2014), p. 165.

X.G. Li, D.W. Zhang, Z.Y. Liu, Z. Li, C.W. Du, and C.F. Dong, Materials science: Share corrosion data, Nature, 527(2015), No. 7579, p. 441.

A.N. Chen, F.H. Cao, X.N. Liao, W.J. Liu, L.Y. Zheng, J.Q. Zhang, and C.A. Cao, Study of pitting corrosion on mild steel during wet-dry cycles by electrochemical noise analysis based on chaos theory, Corros. Sci., 66(2013), p. 183.

Z.F. Wang, F.X. Yin, L.X. Wu, Y.Q. Sun, and W.L. Zhang, Corrosion resistance on high strength bainitic steel and 09CuP-CrNi after wet-dry cyclic conditions, J. Iron Steel Res. Int., 20(2013), No. 2, p. 72.

J.Q. Wu, B. Diao, W.M. Zhang, Y.H. Ye, Z.J. Liu, and D. Wang, Chloride diffusivity and service life prediction of fatigue damaged RC beams under seawater wet-dry environment, Constr. Build. Mater., 171(2018), p. 942.

W. Han, C. Pan, Z.Y. Wang, and G.C. Yu, A study on the initial corrosion behavior of carbon steel exposed to outdoor wet-dry cyclic condition, Corros. Sci., 88(2014), p. 89.

B. Qian, B.R. Hou, and M. Zheng, The inhibition effect of tannic acid on mild steel corrosion in seawater wet/dry cyclic conditions, Corros. Sci., 72(2013), p. 1.

W.K. Hao, Z.Y. Liu, W. Wu, X.G. Li, C.W. Du, and D.W. Zhang, Electrochemical characterization and stress corrosion cracking of E690 high strength steel in wet-dry cyclic marine environments, Mater. Sci. Eng. A, 710(2018), p. 318.

J.X. Yu, H.K. Wang, Y. Yu, Z. Luo, W.D. Liu, and C.M. Wang, Corrosion behavior of X65 pipeline steel: Comparison of wet-dry cycle and full immersion, Corros. Sci., 133(2018), p. 276.

H.Y. Ha, M.H. Jang, T.H. Lee, and J. Moon, Understanding the relation between phase fraction and pitting corrosion resistance of UNS S32750 stainless steel, Mater. Charact., 106(2015), p. 338.

Z.Y. Zhang, H.Z. Zhang, J. Hu, X.X. Qi, Y. Bian, A. Shen, P.P. Xu, and Y.Q. Zhao, Microstructure evolution and mechanical properties of briefly heat-treated SAF 2507 super duplex stainless steel welds, Constr. Build. Mater., 168(2018), p. 338.

Y. Zhao, Y. Wang, S. Tang, W.N. Zhang, and Z.Y. Liu, Edge cracking prevention in 2507 super duplex stainless steel by twin-roll strip casting and its microstructure and properties, J. Mater. Process. Technol., 266(2019), p. 246.

Z.H. Sun, M. Moradi, Y.X. Chen, R. Bagheri, P.S. Guo, L.J. Yang, Z.L. Song, and C. Xu, Simulation of the marine environment using bioreactor for investigation of 2507 duplex stainless steel corrosion in the presence of marine isolated Bacillus Vietnamensis bacterium, Mater. Chem. Phys., 208(2018), p. 149.

Z.Y. Cui, S.S. Chen, Y.P. Dou, S.K. Han, L.W. Wang, C. Man, X. Wang, S.G. Chen, Y.F. Cheng, and X.G. Li, Passivation behavior and surface chemistry of 2507 super duplex stainless steel in artificial seawater: Influence of dissolved oxygen and pH, Corros. Sci., 150(2019), p. 218.

J.M. Pardal, S.S.M. Tavares, M.C. Fonseca, J.A. de Souza, R.R.A. Côrte, and H.F.G. de Abreu, Influence of the grain size on deleterious phase precipitation in superduplex stainless steel UNS S32750, Mater. Charact., 60(2009), No. 3, p. 165.

J.C. de Lacerda, L.C. Cândido, and L.B. Godefroid, Effect of volume fraction of phases and precipitates on the mechanical behavior of UNS S31803 duplex stainless steel, Int. J. Fatigue, 74(2015), p. 81.

C. Lin, X.G. Li, and C.F. Dong, Pitting and galvanic corrosion behavior of stainless steel with weld in wet-dry environment containing CI−, J. Univ. Sci. Technol. Beijing, 14(2007), No. 6, p. 517.

Q. Liu, W. Wu, Y. Pan, Z.Y. Liu, X.C. Zhou, and X.G. Li, Electrochemical mechanism of stress corrosion cracking of API X70 pipeline steel under different AC frequencies, Constr. Build. Mater., 171(2018), p. 622.

N.W. Dai, J. Wu, L.C. Zhang, Y.T. Sun, Y.Y. Liu, Y.Y. Yang, Y.M. Jiang, and J. Li, Alternating voltage induced oscillation on electrochemical behavior and pitting corrosion in duplex stainless steel 2205, Mater. Corros., 70(2019), No. 3, p. 419.

D.K. Kim, S.V. Muralidharan, T.H. Ha, J.H. Bae, Y.C. Ha, H.G. Lee, and J.D. Scantlebury, Electrochemical studies on the alternating current corrosion of mild steel under cathodic protection condition in marine environments, Electrochim. Acta, 51(2006), No. 25, p. 5259.

M. Liu, X.Q. Cheng, X.G. Li, and T.J. Lu, Corrosion behavior of low-Cr steel rebars in alkaline solutions with different pH in the presence of chlorides, J. Electroanal. Chem., 803(2017), p. 40.

J.L. Lv, W.L. Guo, and T.X. Liang, The effect of pre-deformation on corrosion resistance of the passive film formed on 2205 duplex stainless steel, J. Alloys Compd., 686(2016), p. 176.

M.Q. Wang, Z.H. Zhou, Q.J. Wang, Z.H. Wang, X. Zhang, and Y.Y. Liu, Role of passive film in dominating the electrochemical corrosion behavior of FeCrMoCBY amorphous coating, J. Alloys Compd., 811(2019), art. No. 151962.

A. Kocijan, D.K. Merl, and M. Jenko, The corrosion behaviour of austenitic and duplex stainless steels in artificial saliva with the addition of fluoride, Corros. Sci., 53(2011), No. 2, p. 776.

J. Ming and J.J. Shi, Chloride resistance of Cr-bearing alloy steels in carbonated concrete pore solutions, Int. J. Miner. Metall. Mater., 27(2020), No. 4, p. 494.

L.H. Zhang, W. Zhang, Y.M. Jiang, B. Deng, D.M. Sun, and J. Li, Influence of annealing treatment on the corrosion resistance of lean duplex stainless steel 2101, Electrochim. Acta, 54(2009), No. 23, p. 5387.

L. Freire, M.J. Carmezima, M.G.S. Ferreira, and M.F. Montemor, The electrochemical behaviour of stainless steel AISI 304 in alkaline solutions with different pH in the presence of chlorides, Electrochim. Acta, 56(2011), No. 14, p. 5280.

L. Zeng, X.P. Guo, G.A. Zhang, and H.X. Chen, Semiconductivities of passive films formed on stainless steel bend under erosion-corrosion conditions, Corros. Sci., 144(2018), p. 258.

S. Ningshen, U. Kamachi Mudali, V.K. Mittal, and H.S. Khatak, Semiconducting and passive film properties of nitrogen-containing type 316LN stainless steels, Corros. Sci., 49(2007), No. 2, p. 481.

M. Liu, Y.Q. Hao, L.R. Zheng, L. Niu, and D. Miao, Role of coke in the passive properties of vitallium 2000 CoCrMo casting alloy in simulated oral environment, J. Mater. Eng. Perform., 28(2019), No. 12, p. 7527.

Y.J. Guo, T.Y. Sun, J.C. Hu, Y.M. Jiang, L.Z. Jiang, and J. Li, Microstructure evolution and pitting corrosion resistance of the Gleeble-simulated heat-affected zone of a newly developed lean duplex stainless steel 2002, J. Alloys Compd., 658(2016), p. 1031.

L.Q. Guo, M. Li, X.L. Shi, Y. Yan, X.Y. Li, and L.J. Qiao, Effect of annealing temperature on the corrosion behavior of duplex stainless steel studied by in situ techniques, Corros. Sci., 53(2011), No. 11, p. 3733.

N. Sathirachinda, R. Pettersson, and J.S. Pan, Depletion effects at phase boundaries in 2205 duplex stainless steel characterized with SKPFM and TEM/EDS, Corros. Sci., 51(2009), No. 8, p. 1850.

Z.Q. Zhang, H.Y. Jing, L.Y. Xu, Y.D. Han, L. Zhao, and J.L. Zhang, Influence of microstructure and elemental partitioning on pitting corrosion resistance of duplex stainless steel welding joints, Appl. Surf. Sci., 394(2017), p. 297.

Q. Sun, J. Wang, H.B. Li, Y. Li, Y.D. Hu, J.G. Bai, and P.D. Han, Chi phase after short-term aging and corrosion behavior in 2205 duplex stainless steel, J. Iron Steel Res. Int., 23(2016), No. 10, p. 1071.

L.Q. Guo, B.J. Yang, J.Y. He, and L.J. Qiao, Local electrical properties of thermally grown oxide films formed on duplex stainless steel surfaces, Appl. Surf. Sci., 444(2018), p. 48.

L.D. Chen, H. Tan, Z.Y. Wang, J. Li, and Y.M. Jiang, Influence of cooling rate on microstructure evolution and pitting corrosion resistance in the simulated heat-affected zone of 2304 duplex stainless steels, Corros. Sci., 58(2012), p. 168.

B. Deng, Z.Y. Wang, Y.M. Jiang, T. Sun, J.L. Xu, and J. Li, Effect of thermal cycles on the corrosion and mechanical properties of UNS S31803 duplex stainless steel, Corros. Sci., 51(2009), No. 12, p. 2969.

H. Tan, Z.Y. Wang, Y.M. Jiang, Y.Z. Yang, B. Deng, H.M. Song, and J. Li, Influence of welding thermal cycles on microstructure and pitting corrosion resistance of 2304 duplex stainless steels, Corros. Sci., 55(2012), p. 368.

H. Tan, Z.Y. Wang, Y.M. Jiang, D. Han, J.F. Hong, L.D. Chen, L.Z. Jiang, and J. Li, Annealing temperature effect on the pitting corrosion resistance of plasma arc welded joints of duplex stainless steel UNS S32304 in 1.0 M NaCl, Corros. Sci., 53(2011), No. 6, p. 2191.

Y.Z. Yang, Z.Y. Wang, H. Tan, J.F. Hong, Y.M. Jiang, L.Z. Jiang, and J. Li, Effect of a brief post-weld heat treatment on the microstructure evolution and pitting corrosion of laser beam welded UNS S31803 duplex stainless steel, Corros. Sci., 65(2012), p. 472.

L.W. Wang, H.Y. Tian, H. Gao, F.Z. Xie, K. Zhao, and Z.Y. Cui, Electrochemical and XPS analytical investigation of the accelerative effect of bicarbonate/carbonate ions on AISI 304 in alkaline environment, Appl. Surf. Sci., 492(2019), p. 792.

Z.Y. Cui, S.S. Chen, L.W. Wang, C. Man, Z.Y. Liu, J.S. Wu, X. Wang, S.G. Chen, and X.G. Li, Passivation behavior and surface chemistry of 2507 super duplex stainless steel in acidified artificial seawater containing thiosulfate, J. Electrochem. Soc., 164(2017), No. 13, p. C856.

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, R. Arrabal, and E. Matykina, Pitting corrosion behaviour of austenitic stainless steels—Combining effects of Mn and Mo additions, Corros. Sci., 50(2008), No. 6, p. 1796.

C.M. Abreu, M.J. Cristobal, R. Losada, X.R. Nóvoa, G. Pena, and M.C. Pérez, High frequency impedance spectroscopy study of passive films formed on AISI 316 stainless steel in alkaline medium, J. Electroanal. Chem., 572(2004), No. 2, p. 335.

K. Hashimoto, K. Asami, and K. Teramoto, An X-ray photo-electron spectroscopic study on the role of molybdenum in increasing the corrosion resistance of ferritic stainless steels in HC1, Corros. Sci., 19(1979), No. 1, p. 3.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51871026) and the Natural Science Foundation of Zhejiang Province, China (No. LY18E010004), and some experiment works were supported by the National Material Environmental Corrosion Infrastructure, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, M., Zhang, Q., Yuan, Yf. et al. Effect of microstructure and passive film on corrosion resistance of 2507 super duplex stainless steel prepared by different cooling methods in simulated marine environment. Int J Miner Metall Mater 27, 1100–1114 (2020). https://doi.org/10.1007/s12613-020-2094-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2094-0