Abstract

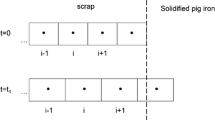

Dephosphorisation basic oxygen furnaces (deP-BOFs) greatly differ from conventional BOFs in the melting process, especially its many limits on adding scrap. A mathematical model of the steel scrap melting process was established in MATLAB to investigate the mechanism of scrap melting in deP-BOF in terms of coupling effects of the carbon content of the molten steel, temperature, scrap preheating and converter blowing time on the melting rate and size of the steel scraps. The scrap melting rate was influenced by both the heat and mass transfer during the melting process: at 1350 °C, when the carbon content was increased from 4.5 to 5.0 mass%, the scrap melting rate increased by 43%; for the carbon content of 4.5 mass%, when the temperature was increased from 1350 to 1400 °C, the scrap melting rate increased by 60%. The carbonisation was found to be the restrictive step of the scrap melting process in deP-BOFs with respect to conventional ones. The scrap heating from room temperature to 800 °C reduced the crusting thickness on the scrap surface but there was no obvious influence on the melting rate. The scrap melting size in the deP-BOF was rather limited by its low melting rate and short melting time.

Similar content being viewed by others

References

S. Asai, I. Muchi, Tetsu-to-Hagane 56 (1970) 546–557.

F. Oeters, Metallurgy of steelmaking, Verlag Stahleisen mbH, Düsseldorf, Germany, 1989.

J. Szekely, Y.K. Chuang, J.W. Hlinka, Metall. Mater. Trans. B 3 (1972) 2825–2833.

A. Kruskopf, L. Holappa, Metall. Res. Technol. 115 (2018) 201.

F.M. Penz, J. Schenk, Steel Res. Int. 90 (2019) 1900124.

R.D. Pehlke, P.D. Goodell, R.W. Dunlap, Trans. Met. Soc. AIME 233 (1965) 1420–1431.

J.H. Li, N. Provatas, G. Brooks, Metall. Mater. Trans. B 36 (2005) 293–302.

K. Isobe, H. Maede, K. Ozawa, K. Umezawa, C. Saito, Tetsu-to-Hagane 76 (1990) 2033–2040.

F.M. Penz, J. Schenk, R. Ammer, G. Klösch, K. Pastucha, M. Reischl, Materials 12 (2019) 1358.

A. Kruskopf, Metall. Mater. Trans. B 46 (2015) 1195–1206.

D.C. Guo, D. Swickard, M. Alavanja, J. Bradley, Iron Steel Technol. (2013) No. 4, 125–132.

A.K. Shukla, B. Deo, D.G.C. Robertson, Metall. Mater. Trans. B 44 (2013) 1407–1427.

H.W. Hartog, P.J. Kreyger, A.B. Snoeijer, CRM 37 (1973) 13–21.

J.K. Wright, Metall. Mater. Trans. B 20 (1989) 363–374.

K. Mandal, G.A. Irons, Metall. Mater. Trans. B 44 (2013) 184–195.

M. Kawakami, K. Takatani, L.C. Brabie, Tetsu-to-Hagane 85 (1999) 658–665.

S. Deng, A. Xu, G. Yang, H. Wang, Steel Res. Int. 3 (2019) 1–10.

M. Kosaka, S. Minowa, Tetsu-to-Hagane 52 (1966) 1429–1432.

K. Mori, H. Nomura, Tetsu-to-Hagane 55 (1969) 347–354.

E.T. Goldfarb, B.E. Sherstov, Inzh-Fiz-Zhur 8 (1970) 492–501.

F. Meng, Fundamentals of metallurgical macro dynamics, Metallurgical Industry Press, Beijing, CN, 2014.

E.T. Turkdogan, Foundamentals of steelmaking, The Institute of Materials, London, UK, 1999.

R.J. Fruehan, Adv. Veter Med AP (1997) 368–375.

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (Grant No. 51674030) and the National Key Research and Development Program of China (Grant No. 2016YFB0601301).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, S., Xu, Aj. Steel scrap melting model for a dephosphorisation basic oxygen furnace. J. Iron Steel Res. Int. 27, 972–980 (2020). https://doi.org/10.1007/s42243-020-00461-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00461-6