Abstract

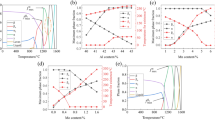

This paper focuses on the study of thermal shock behaviors of a novel TiCx–Ni3(Al,Ti)/Ni functionally graded material (FGM) fabricated from Ti3AlC2 and Ni powders. Thermal shock resistance of resulted FGM was conducted by water quenching at different temperatures, mechanical properties and microstructures after thermal shocks were correspondingly determined and characterized. The microstructure of the FGM after thermal shocks shows no cracks of instability failure between the transition zones, and the reinforcement phases were closely combined with the matrix. Meanwhile, compared with the strength of 1329 MPa without thermal shock, when the temperature of the thermal shock reached 800 °C and 1000 °C respectively, with 10 repeated heat-water quench cycles, the residual flexural strength of FGM decreased slightly, but it could still reach 1100 MPa. Notably, the strength can still maintain at 843 MPa after 10 cycles of thermal shock at 1200 °C. Such excellent thermal shock performance may be the result of the good interfacial bonding and the special gradient structure, the oxidation layer also plays a protective role.

Graphical abstract

Similar content being viewed by others

References

M. Naebe, K. Shirvanimoghaddam, Appl. Mater. Today. 5, 223 (2016)

D.K. Jha, T. Kant, R.K. Singh, Compos. Struct. 96, 833 (2013)

S. Nikbakht, S. Kamarian, M. Shakeri, Compos. Struct. 214, 83 (2019)

G.M. Zheng et al., Compos. Part B. 42, 1813 (2011)

T. Fujii, K. Tohgo, H. Isono, Mater. Sci. Eng., A. 682, 656 (2017).

T. Fujii, K. Tohgo, M. Iwao, J. Alloys. Compd. 766, 1 (2018)

A.F. Baron, J. Guerrero, J.M. González, Ceram. Int. 43, 2592 (2017)

E.O. Ezugwu, Z.M. Wang, A.R. Machado, J. Mater. Proce. Technol. 86, 1 (1999)

P. Gyftou, M. Stroumbouli, E.A. Pavlatou, Electrochim. Acta 50, 4544 (2005)

J.B. Lei, C. Shi, S.F. Zhou, Surf. Coat. Technol. 334, 274 (2018)

F. Li, J. Cheng, S.Y. Zhu, Mater. Sci. Eng., A. 682, 475 (2017).

J. Cai, H.X. Zhang, J.V. Wood, Mater. Sci. Eng. A. 280, 328 (2000)

Z.D. Liu, J. Tian, B. Li, L.P. Zhao, Mater. Sci. Eng., A. 527, 3898 (2010).

C.J. Lu, J. Zhang, T.B. Duan, J. Eur. Ceram. Soc. 36, 3319 (2016)

X.D. Hui, Y.S. Yang, Z.F. Wang, Mater. Sci. Eng., A. 282, 187 (2000).

G.Q. Xiao, Q.C. Fan, M.Z. Gu, Mater. Sci. Eng., A. 382, 132 (2004).

W.J. Wang, V. Gauthier-Brunet, G. P. Bei, Mater. Sci. Eng., A. 530, 168 (2011).

J. Cao, J.K. Liu, X.G. Song, Mater. Des(1980–2015). 56, 115 (2014).

W.Q. Hu, Z.Y. Huang, L.P. Cai, J. Alloys. Compd. 747, 1043 (2018)

J.P. Jiang, S.B. Li, J. Alloys. Compd. 726, 430 (2017)

Z.Y. Huang, J. Bonneville, H.X. Zhai, J. Alloys. Compd. 602, 53 (2014)

M.Q. Li, H.X. Zhai, Z.Y. Huang, J. Alloys. Compd. 628, 186 (2015)

M.Q. Li, H.X. Zhai, Z.Y. Huang, Mater. Sci. Eng., A. 588, 335 (2013).

W.J. Wang, H.X. Zhai, L.L. Chen, Mater. Sci. Eng., A. 670, 351 (2016).

W.Q. Hu, Z.Y. Huang, L.P. Cai, Mater. Charact. 135, 295 (2018)

W.Q. Hu, Z.Y. Huang, L.P. Cai, Mater. Sci. Eng., A. 697, 48 (2017).

W.Q. Hu, Z.Y. Huang, G.M. Zheng, J. Alloys. Compd. 774, 739 (2019)

G.M. Zheng, Z.Y. Huang, Q. Yu, Met. Mater. Int. 26, 905 (2020)

L. Chen, B. Huang, X.L. Yang, J. Alloys. Compd. 780, 388 (2019)

S.L. Wang, Y.R. Sun, L.J. Du, Appl. Surf. Sci. 484, 1282 (2019)

J.S.Hu, B.L. Wang, J.E. Li, Ceram. Int. https://doi.org/10.1016/j.ceramint.2020.01.218

Y.Y. Zhang, L.C. Guo, X.L. Wang, Int. J. Solid. Struct. 164, 202 (2019)

T. Sadowski, K. Nakonieczny, Comput. Mater. Sci. 43, 171 (2008)

Q. Li, D. Cai, Z.H. Yang, Ceram. Int. 45, 8181 (2019)

W. Wang, Q. Li, R. Ma, J. Mater. Proce. Technol. 269, 16 (2019)

Y. Li, J. Wuhan. Univer. Technol. 2009.

Z.R. Xu, Scripta Metall. Mater. (1994).

G.M. Zheng, J. Zhao, C. Jia, Int. J. Refract. Met. Hard. Mater. 35, 55 (2012)

R. Chen, Y.K. Guo, Harbin Univer (Sci, Technol, 2012)

Acknowledgements

This work was supported by National Science Foundation of China (NSFC) under Grant Nos. 51871011, 51572017 and 51301013, by Beijing Government Funds for the Constructive Project of Central Universities, and by fundamental Research Funds for the Central Universities under Grant No. 2018YJS144

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Q., Huang, Z., Zheng, G. et al. Thermal Shock Behavior of a Novel TiCx–Ni3(Al,Ti)/Ni Functionally Graded Composite. Met. Mater. Int. 27, 5133–5144 (2021). https://doi.org/10.1007/s12540-020-00836-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00836-0