Abstract

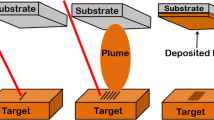

PbS films in undoped state and with various Eu contents (1 wt.%, 3 wt.%, and 5 wt.%) have been coated effectively on insulating glass substrates by a nebulized spray pyrolysis route. The effects of Eu doping on various properties including the photosensitivity of the PbS films were systematically analyzed. X-ray diffraction (XRD) analysis of the materials revealed a polycrystalline nature with crystallites showing simple cubic structure oriented along (200) direction. Based on the XRD data, the crystallite size, dislocation density, and lattice strain of the films with different doping concentrations were calculated and are consistently discussed. The secondary phase Eu3O4 formed when the Eu doping level was higher in the host solution. The Raman peaks detected at 190 cm−1, 236 cm−1, and 465 cm−1 confirmed formation of PbS. Scanning electron microscopy was used to reveal the morphology of the films as a function of the dopant concentration. Important optical properties including the bandgap, absorption coefficient, dielectric constant, index of refraction, and coefficient of extinction of the films are systematically reported. Optical study of the films revealed a variation of the bandgap from 2.14 eV to 2.81 eV with increasing Eu doping level. The 3 wt.% europium-doped PbS film showed better photosensitivity at 100 W/m2 compared with the other films based on current–voltage (I–V) measurements.

Similar content being viewed by others

References

A.N. Banerjee, Nanotechnol. Sci. Appl. 4, 35 (2011).

E. Yücel, Y. Yücel, and B. Beleli, J. Alloys Compd. 642, 63 (2015).

E. Yücel, Y. Yücel, and B. Beleli, J. Cryst. Growth 422, 1 (2015).

J.H. Warner, N. Heckenberg, and H. Rubinsztein-Dunlop, Mater. Lett. 60, 3332 (2006).

B.K. Gupta, R. Thangaraj, and O.P. Agnihotri, Sol. Energy Mater. 1, 481 (1979).

V.L. Colvin, M.C. Schlamp, and A.P. Alivisatos, Nature 370, 354 (1994).

I. Pop, C. Nascu, V. Ionescu, E. Indrea, and I. Bratu, Thin Sol. Films 307, 240 (1997).

H. Hirata and K. Higashiyama, Bull. Chem. Sci. Jpn. 44, 2420 (1971).

P. Nair, V. Garcia, A. Hernandez, and M. Nair, J. Phys. D Appl. Phys. 24, 1466 (1991).

S. Pawar, J. Shaikh, R. Devan, Y. Ma, D. Haranath, P. Bhosale, and P. Patil, Appl. Surf. Sci. 258, 1869 (2011).

T. Fu, Sens. Actuators B Chem. 140, 116 (2009).

X. Shen, Z. Li, Y. Cui, and Y. Pang, Int. J. Electrochem. Sci. 6, 3525 (2011).

R. Tyagi, S. Agarwal and V. Sethi, Electrical and Optical-Properties of Chemically Sprayed Lead Sulfide Films, Council Scientific Industrial Research Publ & Info Directorate, New Delhi City, p. 670 (1977)

G.H. Blount, P.J. Schreiber, D.K. Smith, and R.T. Yamada, J. Appl. Phys. 44, 978 (1973).

G. Kothiyal and B. Ghosh, Prog. Cryst. Growth Charact. Mater. 20, 313 (1990).

Y.J. Yang, Mater. Sci. Eng. B 131, 200 (2006).

Z. Xiu, S. Liu, J. Yu, F. Xu, W. Yu, and G. Feng, J. Alloys Compd. 457, L9 (2008).

B. Thangaraju and P. Kaliannan, Semicond. Sci. Technol. 15, 849 (2000).

J. Puišo, S. Lindroos, S. Tamulevičius, M. Leskelä, and V. Snitka, Thin Solid Films 428, 223 (2003).

A. Martucci, J. Fick, S.-É. LeBlanc, M. LoCascio, and A. HachÉ, J. Non-Cryst. Solids 345–346, 639 (2004).

S.R. Rosario, I. Kulandaisamy, K.D.A. Kumar, K. Ramesh, H.A. Ibrahium, and N.S. Awwad, Int. J. Energy Res. 44, 4505 (2020).

S.R. Rosario, I. Kulandaisamy, A.M.S. Arulanantham, K.D.A. Kumar, S. Valanarasu, M.S. Hamdy, K.S. Al-Namshah, and A.M. Alhanash, Mater. Res. Exp. 6, 056201 (2019).

M. Shkir, K.V. Chandekar, A. Khan, A.M. El-Toni, and S. AlFaify, Mater. Sci. Semicond. Proc. 107, 104807 (2020).

M. Shkir, M.T. Khan, A. Khan, A.M. El-Toni, A. Aldalbahi, and S. AlFaify, Mater. Sci. Semicond. Proc. 96, 16 (2019).

P. Wellenius, A. Suresh, J.V. Foreman, H.O. Everitt, and J.F. Muth, Mater. Sci. Eng. B 146, 252 (2008).

P. Gollakota, A. Dhawan, P. Wellenius, L.M. Lunardi, J.F. Muth, Y.N. Saripalli, H.Y. Peng, and H.O. Everitt, Appl. Phys. Lett. 88, 221906 (2006).

J. Hao, Z. Lou, I. Renaud, and M. Cocivera, Thin Solid Films 467, 182 (2004).

Y. Masuda, M. Yamagishi, and K. Koumoto, Chem. Mater. 19, 1002 (2007).

A. Garcia-Murillo, C. LeLuyer, C. Garapon, C. Dujardin, E. Bernstein, C. Pedrini, and J. Mugnier, Opt. Mater. 19, 161 (2002).

J. Domaradzki, D. Kaczmarek, A. Borkowska, D. Schmeisser, S. Mueller, R. Wasielewski, A. Ciszewski, and D. Wojcieszak, Vacuum 82, 1007 (2008).

K.M. Gadave, S.A. Jodgudri, and C.D. Lokhande, Thin Solid Films 245, 7 (1994).

X. Zheng, F. Gao, F. Ji, H. Wu, J. Zhang, X. Hu, and Y. Xiang, Mater. Lett. 167, 128 (2016).

S. Ravishankar, A.R. Balu, and V.S. Nagarethinam, J. Electron. Mater. 47, 1271 (2018).

M. Shkir, Z.R. Khan, M. Anis, S.S. Shaikh, and S. AlFaify, Chin. J. Phys. 63, 51 (2020).

M. Shkir, I.M. Ashraf, S. AlFaify, A.M. El-Toni, M. Ahmed, and A. Khan, Ceram. Int. 46, 4652 (2019).

A. Singh, V. Viswanath, and V. Janu, J. Lumin. 129, 874 (2009).

T. Rattana, S. Suwanboon, P. Amornpitoksuk, A. Haidoux, and P. Limsuwan, J. Alloys Comp. 480, 603 (2009).

M. Ravikumar, R. Chandramohan, K.D.A. Kumar, S. Valanarasu, A. Kathalingam, V. Ganesh, M. Shkir, and S. AlFaify, J. Sol-Gel. Sci. Technol. 85, 31 (2018).

M. Shkir and S. AlFaify, J. Mater. Res. 34, 2765 (2019).

K.D.A. Kumar, V. Ganesh, S. Valanarasu, M. Shkir, I. Kulandaisamy, A. Kathalingam, and S. AlFaify, Mater. Chem. Phys. 212, 167 (2018).

R. Yousefi, M. Cheraghizade, F. Jamali-Sheini, W.J. Basirun, and N.M. Huang, Curr. Appl. Phys. 14, 1031 (2014).

F. Gode, O. Baglayan, and E. Guneri, Chalcog. Lett. 12, 519 (2015).

Y. Bencherif, A. Boukra, A. Zaoui, and M. Ferhat, Infrared Phys. Technol. 54, 39 (2011).

S.V. Bhatt, M. Deshpande, B.H. Soni, N. Garg and S.H. Chaki: Chemical bath deposition of lead sulphide (PbS) thin film and their characterization, in Solid State Phenomena, (vol. 209, Trans Tech Publ, City, 2014), p. 111

J. Rivera-Nieblas, J. Alvarado-Rivera, M. Acosta-Enríquez, R. Ochoa-Landin, F. Espinoza-Beltrán, A. Apolinar-Iribe, M. Flores-Acosta, A. De Leon, and S. Castillo, Chalcogenide Lett. 10, 349 (2013).

R. Sherwin, R.J.H. Clark, R. Lauck, and M. Cardona, Sol. State Commun. 134, 565 (2005).

E. Sarica and V. Bilgin, Mater. Sci. Semicond. Proc. 68, 288 (2017).

A.M.S. Arulanantham, S. Valanarasu, K. Jeyadheepan, and A. Kathalingam, Thin Solid Films 666, 85 (2018).

E. Yücel and Y. Yücel, Ceram. Int. 43, 407 (2017).

C. Rajashree, A. Balu, and V. Nagarethinam, J. Mater. Sci.: Mater. Electron. 27, 7876 (2016).

G. Singh Lotey, Z. Jindal, V. Singhi, and N.K. Verma, Mater. Sci. Semicond. Proc. 16, 2044 (2013).

R. Palomino-Merino, O. Portillo-Moreno, L. Chaltel-Lima, R.G. Pérez, M. de Icaza-Herrera, and V. Castaño, J. Nanomater. 2013, 45 (2013).

J. Tauc, R. Grigorovici, and A. Vancu, Phys. Stat. Sol. 15, 627 (1966).

T. Moss, G.J. Burrell, and B. Ellis, Semiconductor Opto-Electronics (London: Butterworth-Heinemann, 1959).

M. Arif, M. Shkir, S. AlFaify, A. Sanger, P.M. Vilarinho, and A. Singh, Opt. Laser Technol. 112, 539 (2019).

Y. Gülen, Metall. Mater. Trans. A 46, 4698 (2015).

M. Shkir, M.T. Khan, and S. AlFaify, Appl. Nanosci. 9, 1417 (2019).

J. Kim, E. Oh, R. Xiao, S. Ritter, Y. Yang, D. Yu, J. HeeIm, S. HyukKim, W. JunChoi, and J.-G. Park, Nanotechnology 28, 475706 (2017).

A. De Iacovo, C. Venettacci, L. Colace, L. Scopa, and S. Foglia, Sci. Rep. 6, 1 (2016).

Y. Wei, Z. Ren, A. Zhang, P. Mao, H. Li, X. Zhong, W. Li, S. Yang, and J. Wang, Adv. Funct. Mater. 28, 1706690 (2018).

H. Tang, J. Zhong, W. Chen, K. Shi, G. Mei, Y. Zhang, Z. Wen, P. Müller-Buschbaum, D. Wu, K. Wang, and X.W. Sun, ACS Appl. Nano Mater. 2, 6135 (2019).

Acknowledgments

The authors would like to express their gratitude to Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through Research Groups Program under Grant No. R.G.P.1/207/41. A.K. acknowledges the Researchers Supporting Project (RSP-2019/127), King Saud University, Riyadh, Saudi Arabia for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Paulraj, K., Ramaswamy, S., Saravanakumar, S. et al. Comprehensive Study on Nebulizer-Spray-Pyrolyzed Eu-Doped PbS Thin Films for Optoelectronic Applications. J. Electron. Mater. 49, 5439–5448 (2020). https://doi.org/10.1007/s11664-020-08267-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08267-8