Abstract

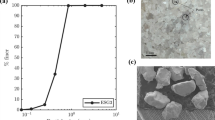

In order to improve the accuracy of the porosity results of pellets, the reliability of three methods for measuring the pore structure was compared. The results show that there is a measurement error in the result of the traditional method, the mercury intrusion porosimetry (MIP) cannot detect closed pores, and the result of scanning electron microscope (SEM) method is more comprehensive. Additionally, three types of pore structures have been proposed to describe the pore formation mechanism of pellets, namely original pores, pores left by shrinkage of liquid phase and pores left by induration of mineral particles. Furthermore, the pore structures of pellets were analyzed by MIP and SEM. The results reveal that MIP can measure the pores with diameters less than 1 μm, and the pore diameters measured by SEM range from 1.2 to 89.2 μm. Finally, the curvature of the pores is measured to evaluate the consolidation degree of the pellet.

Similar content being viewed by others

References

Li W, Wang N, Fu G, Chu M, and Zhu M, Powder Technol 326 (2018) 137.

Forsmo S P E, Forsmo S E, Samskog P O, and Björkman B M T, Powder Technol 2 (2008) 183.

Umadevi T, Sridhara K, Rameshwar S, and Srinidhi R, Trans Indian Inst Met 10 (2019) 72.

Nellros F, and Thurley M J, Miner Eng 14 (2011) 24.

Winkler T, Dai X Y, Mielke G, Vogt S, Buechner H, Schantz J T, Harder Y, Machens H G, Morlock M M, and Schilling A F, JOM 4 (2014) 66.

Voigt C, Jäckel E, Aneziris C G, and Hubálková J, Ceram Int 3 (2013) 39.

Korat L, Ducman V, Legat A, and Mirtič B, Ceram Int 6 (2013) 39.

Cunningham R, Narra S P, Montgomery C, Beuth J, and Rollett A D, JOM 3 (2017) 69.

da Luz F S, Paciornik S, Monteiro S N, da Silva L C, Tommasini F J, and Candido V S, JOM 10 (2017) 69.

Kumar S, and Suman S K, Trans Indian Inst Met 7 (2018) 71.

Kumar P S, Ravi B P, Sivrikaya O, and Nanda R K, Sci Sinter 1 (2019) 51.

Qiu G, Jiang T, Huang Z, Zhu D, and Fan X, ISIJ Int 1 (2003) 43.

Morankar S, Mandal M, Kourra N, Williams M A, Mitra R, and Srirangam P, JOM 11 (2019) 71.

Hinrichsen K O, and Klemm E, Chem Eng Technol 11 (2016) 39.

Meyer M, Lagoeiro L E, Graça L M, and Silva C J, Miner Process Extr Metall Rev 5 (2016) 37.

Meng Q, Wei R, Li J, Wang P, Gao Z, Di Z, and Long H, ISIJ Int 3 (2018) 58.

Gao Q, Jiang X, Zheng H, and Shen F, Minerals 9 (2018) 8.

Harvey T, Honeyands T, O’dea D, and Evans G, ISIJ Int (in press).

Li W, Wang N, Fu G, Chu M, and Zhu M, Ironmak Steelmak 10 (2018) 45.

Umadevi T, Kumar A, Karthik P, Srinidhi R, and Manjini S, Ironmak Steelmak 2 (2018) 45.

Bhuiyan I U, Mouzon J, Forsmo S P E, and Hedlund J, Powder Technol 3 (2011) 214.

Huang Z, Yi L, and Jiang T, Powder Technol 221 (2012) 284.

Bhuiyan I U, Mouzon J, Forsberg F, Forsmo S P E, Sjödahl M, and Hedlund J, Powder Technol 233 (2013) 312.

Xie B, Zhao H, Long H, Peng J, and Liu R, Ceram Int 18 (2019) 45.

Abzalov V M, Klein V I, and Yur’ev B P, Steel Transl 6 (2008) 38.

Lodge K B, Powder Technol 1 (2010) 204.

Epperly W R, Pelletizing of Iron Ore, Springer, Berlin (1980).

Kumar T K S, Simonsson M, Viswanathan N N, Ahmed H, Andersson C, El-Geassy A H A, and Björkman B, Steel Res Int 3 (2018) 89.

Kuila U, and Prasad M, Geophys Prospect 2 (2013) 61.

Giesche H, Part Part Syst Charact 1 (2006) 23.

Meyer K, Pelletization of Iron Ores, Springer-Verlag, (1980) 158.

Berrezueta E, González-Menéndez L, Ordóñez-Casado B, and Olaya P, Comput Geosci 77 (2015) 97.

Xing X, Rogers H, Zhang G, Hockings K, Zulli P, and Ostrovski O, Energy Fuels 1 (2016) 30.

Yuan B, Zhang X P, Chung C Y, Zeng M Q, and Zhu M, Metall Mater Trans A Phys Metall Mater Sci 3 (2006) 37.

Li B Y, Rong L J, and Li Y Y, J Mater Res 10 (1998) 13.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51874025) and supported by the National Key R&D Program of China (2017YFB0304300 & 2017YFB0304302).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, C., Zhang, J., Liu, Z. et al. A Comprehensive Study of Pore Characteristics, Formation Mechanism and Reliability Analysis with Advanced Characterization Methods Within Pellets. Trans Indian Inst Met 73, 2503–2510 (2020). https://doi.org/10.1007/s12666-020-02059-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02059-8