Abstract

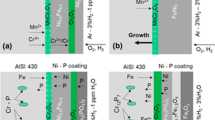

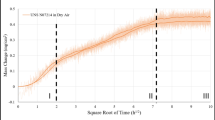

The oxidation behavior of nickel (Ni)-coated AISI 430 alloy was investigated at 800 °C in moisture-saturated (~ 3% H2O) air. Effects of pre-oxidation of AISI 430 in air and inter-diffusion layer (Fe0.5Ni0.5) of Ni-coated AISI 430, in dilute hydrogen (Ar–3%H2) at 800 °C, on the oxidation behavior were also studied. Microstructure, elemental chemistry, and compound/oxide formation across the reaction zones/oxide layer were analyzed by scanning electron microscopy, energy-dispersive spectroscopy, and X-ray diffraction techniques. Multilayered oxides/reaction zones were found for all the samples. Ni-coated AISI 430 exhibits the lowest chromium diffusion into the oxide scale from the AISI 430/oxide scale interface. Pre-oxidation of AISI 430 and inter-diffusion of Ni-coated AISI 430 show excessive chromium diffusion into the reaction zone/oxide scale and interfacial porosity.

Graphic Abstract

Similar content being viewed by others

References

W. Z. Zhu, Development of interconnect materials for solid oxide fuel cells. Mater. Sci. Eng. A. 348, 227–243 (2003).

Z. Yang, Recent advances in metallic interconnects for solid oxide fuel cells. Inter. Mater. Rev. 53, 39–54 (2008).

H. Ebrahimifar and M. Zandrahimi, Influence of oxide scale thickness on electrical conductivity of coated AISI 430 steel for use as interconnect in solid oxide fuel cells. Ionics 18, 615–624 (2012).

M. K. Mahapatra and P. Singh, Fuel cells: energy conversion technology, in Future Energy, ed. T. M. Letcher (Elsevier, London, 2013), pp. 511–547.

P. Alnegren, M. Sattari, J. Froitzheim, and J. E. Svensson, Degradation of ferritic stainless steels under conditions used for solid oxide fuel cells and electrolyzers at varying oxygen pressures. Corr. Sci. 110, 200–212 (2016).

S. P. Jiang and X. Chen, Chromium deposition and poisoning of cathodes of solid oxide fuel cells: A review. Inter. J. Hydrog. Energy. 39, 505–531 (2014).

N. Shaigan, W. Qu, D. G. Ivey, and W. Chen, A review of recent progress in coatings, surface modifications and alloy developments for solid oxide fuel cell ferritic stainless steel interconnects. J. Power Sources. 195, 1529–1542 (2010).

M. Stanislowski, J. Froitzheim, L. Niewolak, et al., Reduction of chromium vaporization from SOFC interconnectors by highly effective coatings. J. Power Sources. 164, 578–589 (2007).

S. Fontana, R. Amendol, S. Chevalier, et al., Metallic interconnects for SOFC: Characterization of corrosion resistance and conductivity evaluation at operating temperature of differently coated alloys. J. Power Sour. 171, 652–662 (2007).

S.-H. Kim, J.-Y. Huh, J.-H. Jun, and J. Favergeon, Thin elemental coatings of yttrium, cobalt, and yttrium/cobalt on ferritic stainless steel for SOFC interconnect applications. Cur. Appl. Phys. 10, S86–S90 (2010).

G. A. Ludwig, M. A. Korb, D. A. S. Lima, et al., Protective coatings for AISI430 stainless steel at high temperatures using perovskite oxides La0.6Sr0.4CoO3 on spinel type oxide NiFe2O4. Ceram. Int. 141, 14561–14573 (2015).

J.-J. Choi, J. Ryu, B.-D. Hahn, et al., Ni-containing conducting ceramic as an oxidation protective coating on metallic interconnects by aerosol deposition. J. Am. Ceram. Soc. 93, 1614–1618 (2010).

C. S. Ni, D. F. Zhang, C. Y. Ni, and Z. M. Wang, Ruddlesdene Popper nickelate as coating for chromia-forming stainless steel. Int. J. Hydrog. Energy. 39, 13314–13319 (2014).

S. Lee, J. Hong, H. Kim, et al., Highly dense Mn-Co spinel coating for protection of metallic interconnect of solid oxide fuel cells. J. Electrochem. Soc. 161, F1389–F1394 (2014).

Z. Yang, G. Xia, S. P. Simner, and J. W. Stevenson, Thermal growth and performance of manganese cobaltite spinel protection layers on ferritic stainless steel SOFC interconnects. J. Electrochem. Soc. 152, 1896–1901 (2005).

Z. Ranjbar-Nouri, M. Soltanieh, and S. Rastegari, Applying the protective CuMn2O4 spinel coating on AISI-430 ferritic stainless steel used as solid oxide fuel cell interconnects. Surf. Coat. Technol. 334, 365–372 (2018).

R. Irankhah, B. Raissi, A. Maghsoudipour, A. Irankhah, and S. Ghashghai, NiFe2O4 spinel protection coating for high-temperature solid oxide fuel cell interconnect application. J. Mater. Eng. Perform. 25, 1515–1525 (2016).

S. N. Hosseini, F. Karimzadeh, M. H. Enayati, and N. M. Sammes, Oxidation and electrical behavior of CuFe2O4 spinel coated Crofer 22 APU stainless steel for SOFC interconnect application. Solid State Ionics. 289, 95–105 (2016).

S. Joshi, C. Silva, P. Wang, Y. Mozharivskyj, and A. Petric, Copper-magnesium-manganese spinel coatings for solid oxide fuel cell interconnects. J. Electrochem. Soc. 161, F233–F238 (2014).

J. G. Grolig, P. Alnegren, J. Froitzheim, and J. E. Svensson, Copper iron conversion coating for solid oxide fuel cell interconnects. J. Power Sour. 297, 534–539 (2015).

S. Geng, Q. Zhao, Y. Li, et al., Sputtered MnCu metallic coating on ferritic stainless steel for solid oxide fuel cell interconnects application. Int. J. Hydrog. Energy 42, 10298–10307 (2017).

H. Ebrahimifar and M. Zandrahimi, Oxidation and electrical behavior of Mn-Co-coated Crofer 22 APU steel produced by a pack cementation method for SOFC interconnect applications. Oxid. Met. 84, 129–149 (2015).

P. F. You, X. Zhang, H. L. Zhang, H. J. Liu, and C. L. Zeng, Effect of CeO2 on oxidation and electrical behaviors of ferritic stainless steel interconnects with Ni-Fe coatings. Int. J. Hydrog. Energy. 43, 7492–7500 (2018).

M. V. Glazoff, S. N. Rashkeev, and J. S. Herring, Controlling chromium vaporization from interconnects with nickel coatings in solid oxide devices. Int. J. Hydrog. Energy 39, 15031–15038 (2014).

S. Geng, Q. Wang, W. Wang, S. Zhu, and F. Wang, Sputtered Ni coating on ferritic stainless steel for solid oxide fuel cell interconnect application. Int. J. Hydrog. Energy 37, 916–920 (2012).

K. A. Nielsen, A. R. Dinesen, L. Korcakova, et al., Testing of Ni-plated ferritic steel interconnect in SOFC stacks. Fuel Cells 6, 2006 (100–106).

M. K. King and M. K. Mahapatra, Microstructure of electrodeposited nickel: role of additives. J. Mater. Eng. Perf. (under review).

K. Wang, Y. Liu, and J. W. Fergus, Interactions between SOFC interconnect coating materials and chromia. J. Amer. Ceram. Soc. 94, 4490–4495 (2011).

Ho CY, T.K. Chu TK. Electrical resistivity and thermal conductivity of nine selected AISI steel. Cindas Report 45 (1977).

M. K. King and M. K. Mahapatra, Oxidation of electroless Ni–P coated AISI 430 alloy and effect of pre-reduction. SN Appl. Sci. 2, 716 (2020).

S. J. Hearne and J. A. Floro, Mechanisms inducing compressive stress during electrodeposition of Ni. J. Appl. Phys. 97, 014901 (2005).

M. K. King and M. K. Mahapatra, Corrosion of nickel and nickel-phosphorous coated AISI 430 in dry (Ar-3%H2) and humid hydrogen (Ar-3%H2 -3% H2O) atmosphere. J. Mater. Res. (accepted).

D. Connetable, M. David, A. Prillieux, D. Young, and D. Monceau, Impact of the clusterization on the solubility of oxygen and vacancy concentration in nickel: A multi-scale approach. J. Alloys Comp. 708, 1063–1072 (2017).

K. Hirano, M. Cohen, and B. L. Averbach, Diffusion of nickel into iron. Acta Metall. 9, 440–445 (1961).

C. F. Heuer, Diffusion of iron and cobalt in nickel single crystals. Ph.D. thesis, Missouri University of Science and Technology (1969).

A. Atkinson, A quantitative demonstration of the grain boundary diffusion mechanism for the oxidation of metals. Philos. Mag. A 45, 823–833 (1982).

S. Perusin, B. Viguier, D. Monceau, L. Ressier, and E. Andrieu, Injection of vacancies at metal grain boundaries during the oxidation of nickel. Acta Mater. 52, 5375–5380 (2004).

E. Essuman, G. H. Meier, J. Żurek, M. Hänsel, and W. J. Quadakkers, The effect of water vapor on selective oxidation of Fe-Cr alloy. Oxi. Metals. 69, 143–162 (2008).

R. E. Lobnig, Diffusion of cations in chromia layers grown on iron-base alloys. Oxid Metals. 37, 81–93 (1992).

M. A. Rhamdhani, P. C. Hayes, and E. Jak, Subsolidus phase equilibria of the Fe-Ni-O System. Metal. Mater. Trans. B 39, 690–701 (2008).

A. Col, V. Parry, and C. Pascal, Oxidation of Fe-18Cr-8Ni austenitic stainless steel at 850°C in O2: Microstructure evolution during breakaway oxidation. Corr. Sci. 114, 17–27 (2017).

L. Latu-Romaina, Y. Parsa, S. Mathieu, et al., Towards the growth of stoichiometric chromia on pure chromium by the control of temperature and oxygen partial pressure. Corr. Sci. 126, 238–246 (2017).

J. D. Tucker, R. Najafabadi, T. R. Allen, and D. Morgan, Ab initio-based diffusion theory and tracer diffusion in Ni–Cr and Ni–Fe alloys. J. Nucl. Mater. 405, 216 (2010).

N. Birks, G. M. Meier, and F. S. Pettit, Introduction to high temperature oxidation of metals, 2nd ed, (Cambridge University Press, Cambridge, 2006).

Acknowledgements

US Department of Energy funded the research under the Grant No. DE-FE 0023385. One author (MK) is grateful to NASA Alabama Space Grant Consortium (ASGC) for the financial support to pursue Ph.D. study (Grant No. NNX15AJ18H).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

King, M.K., Mahapatra, M.K. Oxidation of Nickel-Coated AISI 430 Alloy: Effect of Pre-oxidation and Fe0.5Ni0.5 Inter-diffusion Layer. Oxid Met 94, 359–381 (2020). https://doi.org/10.1007/s11085-020-09996-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09996-1