Abstract

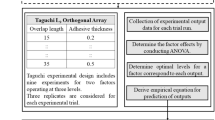

The configuration of adhesive bonding, especially adhesive–adherent interface, is very important in adhesive bonding. Adherend thickness, overlap length and adherend width have a great effect on failure load. It is important to know the effect of these parameters in the estimation of failure load. In this study, two models based on data mining techniques were generated for the estimation of the effect of adherend thickness, width and overlap length on failure load in adhesively bonding joints. One of the models is based on the M5P model tree and the other is based on the M5 rule algorithm. Experimental data were used to evaluate the performance of the models. The correlation coefficient parameter was used to compare the models’ performance. The evaluated correlation coefficient is 93% for the M5P model tree and 96% for the M5 rule.

Similar content being viewed by others

References

Khoramishad H, Razavi SMJ (2014) Metallic fiber-reinforced adhesively bonded joints. Int J Adhes Adhes 55:114–122. https://doi.org/10.1016/j.ijadhadh.2014.08.005

He X (2011) A review of finite element analysis of adhesively bonded joints. Int J Adhes Adhes 31:248–264. https://doi.org/10.1016/j.ijadhadh.2011.01.006

da Silva LFM, Öchsner A, Adams RD (eds) (2011) Handbook of adhesion technology. Springer, Berlin

da Silva LFM, Pirondi A, Öchsner A (2011) Hybrid adhesive joints. Springer, Berlin

Ribeiro TEA, Campilho RDSG, da Silva LFM, Goglio L (2016) Damage analysis of composite–aluminium adhesively-bonded single-lap joints. Compos Struct 136:25–33. https://doi.org/10.1016/j.compstruct.2015.09.054

Liu X, Wang G (2007) Progressive failure analysis of bonded composite repairs. Compos Struct 81:331–340. https://doi.org/10.1016/j.compstruct.2006.08.024

Nguyen T-C, Bai Y, Zhao X-L, Al-Mahaidi R (2011) Mechanical characterization of steel/CFRP double strap joints at elevated temperatures. Compos Struct 93:1604–1612. https://doi.org/10.1016/j.compstruct.2011.01.010

Temiz Ş (2006) Application of bi-adhesive in double-strap joints subjected to bending moment. J Adhes Sci Technol 20:1547–1560. https://doi.org/10.1163/156856106778884262

Ozel A, Yazici B, Akpinar S et al (2014) A study on the strength of adhesively bonded joints with different adherends. Compos Part B Eng 62:167–174. https://doi.org/10.1016/j.compositesb.2014.03.001

Çitil Ş, Temiz Ş, Altun H, Özel A (2011) Determination of mechanical properties of double-strap adhesive joints with an embedded patch. J Adhes Sci Technol 25:2555–2567. https://doi.org/10.1163/016942411X580225

Akhavan-Safar A, Ayatollahi MR, da Silva LFM (2017) Strength prediction of adhesively bonded single lap joints with different bondline thicknesses: a critical longitudinal strain approach. Int J Solids Struct 109:189–198. https://doi.org/10.1016/j.ijsolstr.2017.01.022

Ayatollahi MR, Akhavan-Safar A (2015) Failure load prediction of single lap adhesive joints based on a new linear elastic criterion. Theor Appl Fract Mech 80:210–217. https://doi.org/10.1016/j.tafmec.2015.07.013

Ayaz Y, Çitil Ş, Şahan MF (2016) Repair of small damages in steel pipes with composite patches. Mat-wiss u Werkstofftech 47:503–511. https://doi.org/10.1002/mawe.201600526

Çitil Ş, Ayaz Y, Temiz Ş (2017) Stress analysis of adhesively bonded double strap joints with or without intermediate part subjected to tensile loading. J Adhes 93:343–356. https://doi.org/10.1080/00218464.2015.1075885

Temiz Ş, Adin H, Sülü IY (2015) Behaviour of bi-adhesive in double-strap joint with embedded patch subjected to bending. J Theor Appl Mech 45:83–96. https://doi.org/10.1515/jtam-2015-0019

Çitil Ş (2019) Investigation of curved and scarf lap joints subjected to tensile loads using the cohesive zone model. Proc Inst Mech Eng Part C J Mech Eng Sci 233:6149–6156. https://doi.org/10.1177/0954406219858186

Baykal A (2006) Veri madenciliği uygulama alanları. DÜ Ziya Gökalp Eğitim Fakültesi Dergisi 7:95–107

Sakla SSS, Ashour AF (2005) Prediction of tensile capacity of single adhesive anchors using neural networks. Comput Struct 83:1792–1803. https://doi.org/10.1016/j.compstruc.2005.02.008

Domińczuk J, Kuczmaszewski J (2008) Modelling of adhesive joints and predicting their strength with the use of neural networks. Comput Mater Sci 43:165–170. https://doi.org/10.1016/j.commatsci.2007.07.052

Tosun E, Çalık A (2016) Failure load prediction of single lap adhesive joints using artificial neural networks. Alex Eng J 55:1341–1346. https://doi.org/10.1016/j.aej.2016.04.029

Gültekin K (2014) Yapıştırıcıyla Birleştirilmiş Bağlantılarda Malzeme Genişliğinin Ve Kalınlığının Bağlantının Yük Taşıma Kapasitesine Etkisi Yüksek Lisans Tezi, Atatürk Üniversitesi

Gültekin K, Akpinar S, Özel A (2014) The effect of the adherend width on the strength of adhesively bonded single-lap joint: experimental and numerical analysis. Compos Part B Eng 60:736–745. https://doi.org/10.1016/j.compositesb.2014.01.022

López-Serrano PM, López Sánchez CA, Solís-Moreno R, Corral-Rivas JJ (2016) Geospatial estimation of above ground forest biomass in the sierra madre occidental in the state of Durango. Mexico Forests 7:70. https://doi.org/10.3390/f7030070

Quinlan JR (1992) Learning with continuous classes. Singapore, pp 343–348

Wang Y, Witten IH (1996) Induction of model trees for predicting continuous classes. Working paper 96/23. Department of Computer Science, University of Waikato, Hamilton, New Zealand

Witten IH, Frank E (2005) Data mining: practical machine learning tools and techniques. Morgan Kaufmann, San Francisco

Kumar SA, Vijayalakshmi MN (2012) A naïve based approach of model pruned trees on learner’s response. IJ Mod Educ Comput Sci 9:52–57

Ayaz Y, Kocamaz AF, Karakoç MB (2015) Modeling of compressive strength and UPV of high-volume mineral-admixtured concrete using rule-based M5 rule and tree model M5P classifiers. Constr Build Mater 94:235–240

Angelina N, Jovanović V (2015) The selectıon of optımal data mınıng method for small-sızed hotels. In: Presented at the SYNTHESIS 2015, international scientific conference of IT and business, Belgrade

Roberts F, Roberts D. Statistics 2 - correlation coefficient and coefficient of determination. https://mathbits.com/MathBits/TISection/Statistics2/correlation.htm. Accessed 24 Dec 2019

GISGeography (2015) 10 open source remote sensing software packages. https://gisgeography.com/open-source-remote-sensing-software-packages/. Accessed 25 Dec 2019

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declare that there is no conflict of interest.

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ayaz, Y. Predicting the effect of adherend dimensions on the strength of adhesively bonded joints using M5P and M5 classifiers. J Braz. Soc. Mech. Sci. Eng. 42, 465 (2020). https://doi.org/10.1007/s40430-020-02547-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02547-4