Abstract

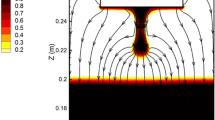

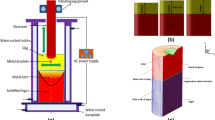

A transient three-dimensional (3D) sequentially coupled mathematical model has been developed to explore multiphysical fields in the twin-electrode electroslag remelting (TE-ESR) furnace. The mechanical APDL module based on the finite element method and the Fluid Dynamics module based on the finite volume method were used to resolve the electromagnetic field and simulate the fluid flow, heat transfer, and solidification process, respectively. The resulting electromagnetic force and Joule heating were incorporated into the source terms of Navier–Stokes and energy conservation equations, respectively. The motion of molten metal droplets and fluctuation of slag/metal interface were tracked by the volume of fluid (VOF) approach. The enthalpy-based technique was employed to simulate the solidification. The results show that the current density is distributed uniformly due to the proximity effect. This is very different from the traditional ESR process during which the skin effect phenomenon is dominated. Besides, the current density is mainly distributed in the slag, only one-fifth flowing through the ingots. The magnitude of velocities in the molten slag is two orders of magnitude higher than those in the steel. The highest temperature zone in the TE-ESR process occurs in the middle of twin-electrode, whereas in the traditional ESR process it occurs beneath the electrode tip. Finally, parametric studies including melting rate, slag thickness, electrode diameter, and center distance have been conducted in detail.

Similar content being viewed by others

Abbreviations

- \( A_{x} \) :

-

x component of magnetic flux density (T)

- \( A_{y} \) :

-

y component of magnetic flux density (T)

- \( A_{z} \) :

-

z component of magnetic flux density (T)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {A} \) :

-

Magnetic potential vector [(V s)/m]

- \( A_{\text{s}} \) :

-

Mushy zone constant (Pa s/m2)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {B} \) :

-

Magnetic flux density (T)

- \( C_{\text{h}} \) :

-

Heat capacity (J/(kg K))

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {D} \) :

-

Electric flux density(C/m2)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {E} \) :

-

Electric field intensity (N/C)

- \( f_{\text{l}} \) :

-

Liquid fraction

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {F}_{\text{eff}} \) :

-

Lorentz force (N/m3)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {F}_{\text{buo}} \) :

-

Buoyancy force (N/m3)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {F}_{\text{sou}} \) :

-

Damping force (N/m3)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {g} \) :

-

Acceleration due to the gravitational force (m2/s)

- \( h_{{}} \) :

-

Sensible enthalpy (J/kg)

- \( h_{\text{ref}} \) :

-

Reference enthalpy (J/kg)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {H} \) :

-

Magnetic field intensity (A/m)

- \( H \) :

-

Enthalpy (J/kg)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {J} \) :

-

Current density (A/m2)

- \( L \) :

-

Latent heat (J/kg)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {P} \) :

-

Pressure (Pa)

- \( Q_{\text{total}} \) :

-

Joule heating (W/m3)

- Rem :

-

Magnetic Reynolds number

- \( t \) :

-

Time (s)

- \( T \) :

-

Temperature (K)

- T l :

-

Liquidus temperature (K)

- \( T_{\text{ref}} \) :

-

Reference temperature (K)

- Ts :

-

Solidus temperature (K)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {v} \) :

-

Velocity (m/s)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {v}_{\text{cast}} \) :

-

Casting velocity (m/s)

- x, y, z :

-

Cartesian coordinates

- \( \alpha \) :

-

Volume fraction

- \( \beta \) :

-

Thermal expansion coefficient (1/K)

- \( \lambda_{\text{p}} \) :

-

Effective thermal conductivity (W/(m K))

- \( \mu \) :

-

Dynamic viscosity (Pa s)

- \( \mu_{\text{eff}} \) :

-

Effective viscosity (Pa s)

- \( \rho \) :

-

Density (kg/m3)

- \( \sigma \) :

-

Electrical conductivity (1/(Ω m))

- \( \varphi \) :

-

Electric potential (V)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {\omega } \) :

-

Joule heating power density(kW/m3)

References

A. Kharicha, E. Karimi-Sibaki, M.Wu, A. Ludwig, and J. Bohacek: Steel Res.Int., 2018, vol.89, 1700100.

C. Z. Wang, J. C. Song, S. Li, Mater. Res. Innovations., 2015, vol.19, pp. 222

F. Wang and B. Li: 140th TMS Annual Meeting and Exhibition, San Diego, CA, 2011, pp. 779–86.

4.B. Li, B. Wang and T. Fumitaka: Metall. Mater. Trans. B., 2014, vol.45, pp.1122-32.

A. Dilawari and J. Szekely: Metall. Mater. Trans. B., 1977, 8B, pp. 227-36.

S. Vishwanathan, D.K. Melgaard, A.D. Patel and D.G. Evans: International Symposium on Liquid Metal Processing and Casting, Santa Fe, 2005, pp. 145–54.

7.F. Wang, Q. Wang and B.K. Li: ISIJ Int., 2017, vol.57, pp. 91-9.

A. Kharicha, M. Wu and A. Ludwig: Metall. Mater. Trans. B., 2016, vol.47, pp.1427-34.

M. Hugo, B. Dussoubs, A. Jardy, J. Escaffre and H Poisson: Metall. Mater. Trans. B., 2016, vol.47, pp.2607-22.

10.Q. Wang, Z. He, G. Li and B. Li: Appl. Therm. Eng. 2016, vol. 103, pp.419-27.

L.B. Medovar, A.K. Tsykulenko, A.V. Chernets, B. B. Fedorovskii, V.E. Shevchenko, I.A. Lantsman, T.F. Grabovskii, V.I. Us, and V.L. Petrenko: Adv. Spec. Electrometall., 2000, vol. 16, pp. 193–96.

A.K. Tskulenko, I.A. Lantsman, L.B. Medovar, A.V. Chernets, V. E. Shevchenko, B.B. Fedorovskii, T.F. Grabovskii, and V.I. Us: Adv. Spec. Electrometall., 2000, vol. 16, pp. 141–44.

Y. Dong, Z, Hou, Z Jiang and H. Liu: Metall. Mater. Trans. B., 2018, vol.49, pp.349-360.

N. Ren, B. Li, L. Li, F. Qi and Z.Q. Liu: Ironmaking Steelmaking., 2018, vol 45, pp.1-10.

F. Wang, Y. Xiong, B. Li and F. Liu: Steel Res. Int., 2019, vol.89, 1800481.

Y.M. Ferng, C.C. Chieng, and C. Pan: Numer. Heat Transf. A, 1989, vol. 16, pp. 429–49.

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Ryberon, V.Schmitt, S. Hans, and H. Poisson: Metall. Mater. Trans. B, 2009, vol. 42, pp. 271–80.

O. Biro and K. Preis: IEEE Trans. Magn., 1989, vol. 25, pp. 3145–59.

J. Baleta, M. Martinjak, M.Vujanović, K. Pachler, J. Wang, N.Duić: J. Environ. Manage., 2017, vol.203, pp.1047-61.

A. Jardy, D. Ablitzer, and J.F. Wadier: Metall. Trans. B, 1991, vol. 22, pp. 111–20.

M. Choudhary and J. Szekely: Metall. Trans. B, 1980, vol. 11, pp. 439–53.

A. Ruckert and H. Pfeifer: International Scientific Colloquium Modelling for Electromagnetic Processing, Hannover, 2008, pp. 27–29.

A. Kharicha, W. Schutzenhofer, A. Ludwig, G. Reiter, and M. Wu: Steel Res. Int., 2008, vol. 79, pp. 632–36.

A. Mitchell: Mater. Sci. Technol., 2009, vol. 25, pp. 186–90.

A. Kharicha, W. Schutzenhofer, A. Ludwig, G. Reiter, and M. Wu: Int. J. Cast Met. Res., 2009, vol. 22, pp. 155–59.

J. Baleta, F. Qi, M. Zivic and M. Lovrenic-Jugovic: Therm. Sci., 2018, vol.22, pp.1943–53.

B. Hernandez-Morales and A. Mitchell: Ironmak. Steelmak., 1999, vol. 26, pp. 423–38.

A. Mitchell: Mat. Sci. Eng. A, 2005, vol. 413, pp. 10–18.

E. Karimi-Sibaki, A. Kharicha and J. Bohacek: Metall. Mater. Trans. B., 2015, vol.46, pp.2049-61.

F. Wang, Q. Wang, J. Baleta and B. Li: JOM, 2019, vol.71, pp.1-8.

Q. Wang and B. Li: ISIJ Int., 2016, vol.56, pp.282-7.

Q. Wang and B. Li: Appl. Therm. Eng.. 2015, vol. 81, pp.116-25.

F. Wang, Y. Xiong, B. Li and F. Liu: Steel Res. Int., 2019, vol.89, 1800092.

Acknowledgments

The authors’ gratitude goes to Key Program of Funds of the National Natural Science Foundation of China (Grant No. 51934002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 18, 2020.

Rights and permissions

About this article

Cite this article

Wang, F., Wang, Q., Baleta, J. et al. Sequentially Coupled Simulation of Multiphysical Fields During Twin-Electrode Electroslag Remelting Process. Metall Mater Trans B 51, 2285–2297 (2020). https://doi.org/10.1007/s11663-020-01928-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01928-3