Abstract

Background

The interfacial peeling strength of lithium-ion battery electrodes is a very important mechanical property that significantly affects the electrochemical performance of battery cells.

Objective

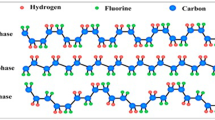

To characterize the interfacial peeling strength of an electrode, an analytical model based on the energy balance principle is established by considering the state of charge (SOC), the energy release rate, the tensile stiffness, and the peeling angle.

Methods

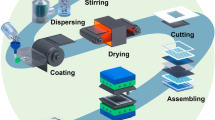

Uniaxial tensile tests and 180-degree peeling tests are conducted to determine the Young’s modulus and the interfacial peeling strengths of electrodes at different SOCs, respectively. The experimental data serve as a validation of the accuracy of the analytical model.

Results

The interfacial peeling strength of the electrode shows a strong reliance on many factors. Specifically, the interfacial peeling strength increases with the SOC and the energy release, and decreases with the peeling angle. When the tensile stiffness of the active layer equals that of the current collector, the interfacial peeling strength has a maximum value.

Conclusions

By comparing with experimental data of the 180-degree peeling test, the model prediction shows excellent agreement at different SOCs, and the analytical model established in this paper can be used to guide and assess the interfacial properties of electrodes for industry.

Similar content being viewed by others

References

Jangid MK, Mukhopadhyay A (2019) Real-time monitoring of stress development during electrochemical cycling of electrode materials for Li-ion batteries: overview and perspectives. J Mater Chem A 7(41):23679–23726

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Yao Y, McDowell MT, Ryu I, Wu H, Liu N, Hu L, Nix WD, Cui Y (2011) Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett 11(7):2949–2295

Wang YK, Dang DY, Li DW, Hu JZ, Zhan XW, Cheng YT (2019) Effects of polymeric binders on the cracking behavior of silicon composite electrodes during electrochemical cycling. J Power Sources 438:1–8

Jangid MK, Sonia FJ, Kali R, Ananthoju B, Mukhopadhyay A (2017) Insights into the effects of multi-layered graphene as buffer/interlayer for a-Si during lithiation/delithiation. Carbon 111:602–616

Chen N, Silberstein MN (2018) Determination of bond strengths in non-woven fabrics: a combined experimental and computational approach. Exp Mech 58(2):343–355

Liu SL, Zhong HX, Zhang CC, Yan XD, Zhao XY, Zhang LZ (2019) Improving the processability and cycling stability of nano-LiFePO4 cathode by using PVDF/TX binary binder. Compos Interface 26(11):1013–1024

Lee J-H, Paik U, Hackley VA, Choi Y-M (2006) Effect of poly (acrylic acid) on adhesion strength and electrochemical performance of natural graphite negative electrode for lithium-ion batteries. J Power Sources 161(1):612–616

Park H-K, Kong B-S, Oh E-S (2011) Effect of high adhesive polyvinyl alcohol binder on the anodes of lithium ion batteries. Electrochem Commun 13(10):1051–1053

Hu JZ, Wang YK, Li DW, Cheng YT (2018) Effects of adhesion and cohesion on the electrochemical performance and durability of silicon composite electrodes. J Power Sources 397:223–230

Chen JCM, Yang JH, Cheng MMC (2019) Induced nanoscale roughness of current collectors enhances lithium ion battery performances. J Power Sources 430:169–174

Maranchi JP, Hepp AF, Evans AG, Nuhfer NT, Kumta PN (2006) Interfacial properties of the a-Si/cu: active-inactive thin-film anode system for lithium-ion batteries. J Electrochem Soc 153(6):A1246–A1253

Wang Y, Pu Y, Ma Z, Pan Y, Sun CQ (2016) Interfacial adhesion energy of lithium-ion battery electrodes. Extreme Mech Lett 9:226–236

Wang C (1999) Measurements of interfacial strength from the blister test. J Appl Polym Sci 73(10):1899–1912

Son B, Ryou M-H, Choi J, Lee T, Yu HK, Kim JH, Lee YM (2014) Measurement and analysis of adhesion property of lithium-ion battery electrodes with SAICAS. ACS Appl Mater Interfaces 6(1):526–531

Kim K, Byun S, Cho I, Ryou MH, Lee YM (2016) Three-dimensional adhesion map based on surface and interfacial cutting analysis system for predicting adhesion properties of composite electrodes. ACS Appl Mater Interfaces 8(36):23688–23695

Kim K, Byun S, Choi J, Hong S, Ryou M-H, Lee YM (2018) Elucidating the polymeric binder distribution within lithium-ion battery electrodes using SAICAS. ChemPhysChem 19(13):1627–1634

Haselrieder W, Westphal B, Bockholt H, Diener A, Höft S, Kwade A (2015) Measuring the coating adhesion strength of electrodes for lithium-ion batteries. Int J Adhes Adhes 60:1–8

Kendall K (1971) The adhesion and surface energy of elastic solids. J Appl Phys D: Appl Phys 4(8):1186–1195

Kendall K (1975) Thin-film peeling-the elastic term. J Appl Phys D: Appl Phys 8(13):1449–1452

Gent AN, Hamed GR (1975) Peel mechanics. J Adhes Dent 7(2):91–95

Gent AN, Kaang SY (1987) Effect of peel angle upon peel force. J Adhes Dent 24(2–4):173–181

Kinloch AJ, Lau CC, Williams JG (1994) The peeling of flexible laminates. Int J Fract 66(1):45–70

Hui CY, Liu ZZ, Minsky H, Creton C, Ciccotti M (2018) Mechanics of an adhesive tape in a zero degree peel test: effect of large deformation and material nonlinearity. Soft Matter 14(47):9681–9692

Liu Z, Minsky H, Creton C, Ciccotti M, Hui C-Y (2019) Mechanics of zero degree peel test on a tape — effects of large deformation, material nonlinearity, and finite bond length. Extreme Mech Lett 32:100518

Capraz OO, Rajput S, White S, Sottos NR (2018) Strain evolution in lithium manganese oxide electrodes. Exp Mech 58(4):561–571

Xie HM, Qiu W, Song HB, Tian JH (2016) In situ measurement of the deformation and elastic modulus evolution in Si composite electrodes during electrochemical lithiation and delithiation. J Electrochem Soc 163(13):A2685–A2690

Xie HM, Song HB, Kang YL, Wang JS (2018) In situ experimental measurement of the mechanical properties of carbon-based electrodes during the electrochemical process. J Electrochem Soc 165(10):A2069–A2074

Zhou DY, Kim C, Yun S (2018) Effective modulus of graphite electrode in Li-ion battery by considering ion concentration, porosity, and binding energy during lithium intercalation. Mater Lett 224:46–49

Qi Y, Guo HB, Hector LG, Timmons A (2010) Threefold increase in the young's modulus of graphite negative electrode during lithium intercalation. J Electrochem Soc 157(5):A558–A566

Xu J, Jia Y, Liu B, Zhao H, Yu H, Li J, Yin S (2018) Coupling effect of state-of-health and state-of-charge on the mechanical integrity of lithium-ion batteries. Exp Mech 58(4):633–643

Guo ZS, Liu C, Lu B, Feng JM (2019) Theoretical and experimental study on the interfacial adhesive properties of graphite electrodes in different charging and aging states. Carbon 150:32–42

Li DW, Li ZZ, Song YC, Zhang JQ (2016) Analysis of diffusion induced elastoplastic bending of bilayer lithium-ion battery electrodes. Appl Math Mech-Engl 37(5):659–670

Moreno-Couranjou M, Manakhov A, Boscher ND, Pireaux J-J, Choquet P (2013) A novel dry chemical path way for diene and dienophile surface functionalization toward thermally responsive metal–polymer adhesion. ACS Appl Mater Interfaces 5(17):8446–8456

Ponce S, Bico J, Roman B (2015) Effect of friction on the peeling test at zero-degrees. Soft Matter 11(48):9281–9290

Chu HC, Tuan HY (2017) High-performance lithium-ion batteries with 1.5 um thin copper nanowire foil as a current collector. J Power Sources 346:40–48

Choi JY, Lee DJ, Lee YM, Lee YG, Kim KM, Park JK, Cho KY (2013) Silicon nanofibrils on a flexible current collector for bendable lithium-ion battery anodes. Adv Funct Mater 23(17):2108–2114

Guo RN, Zhang SL, Ying HJ, Yang WT, Wang JL, Han WQ (2019) Preparation of an amorphous cross-linked binder for silicon anodes. ChemSusChem 12(21):4838–4845

Maleki H, Deng GP, Anani A, Howard J (1999) Thermal stability studies of Li-ion cells and components. J Electrochem Soc 146:3224–3229

Maleki H, Deng GP, Kerzhner-Haller I, Anani A, Howard JN (2000) Thermal stability studies of binder materials in anodes for lithium-ion batteries. J Electrochem Soc 147:4470–4475

Song YC, Shao XJ, Guo ZS, Zhang JQ (2013) Role of material properties and mechanical constraint on stress-assisted diffusion in plate electrodes of lithium ion batteries. J Phys D Appl Phys 46(10):1–10

Takahashi K, Srinivasan V (2015) Examination of graphite particle cracking as a failure mode in lithium-ion batteries: a model-experimental study. J Electrochem Soc 162(4):A635–A645

Yin J, Shao XJ, Lu B, Song YC, Zhang JQ (2018) Two-way coupled analysis of lithium diffusion and diffusion induced finite elastoplastic bending of bilayer electrodes in lithium-ion batteries. Appl Math Mech: Engl 39(11):1567–1586

Padhye N, Parks DM, Slocum AH, Trout BL (2016) Enhancing the performance of the T-peel test for thin and flexible adhered laminates. Rev Sci Instrum 87:1–10

Bai RB, Chen BH, Yang JW, Suo ZG (2019) Tearing a hydrogel of complex rheology. J Mech Phys Solids 125:749–761

Acknowledgements

Authors gratefully acknowledge the financial support of the National Science Foundation of China (No. 11972218 and 11472165).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, P.Y., Liu, C., Guo, Z.S. et al. Analytical Model and Experimental Verification of the Interfacial Peeling Strength of Electrodes. Exp Mech 61, 321–330 (2021). https://doi.org/10.1007/s11340-020-00651-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00651-z