Article contents

Dynamic interactions of ingested molten silicate particles with air plasma sprayed thermal barrier coatings

Published online by Cambridge University Press: 10 August 2020

Abstract

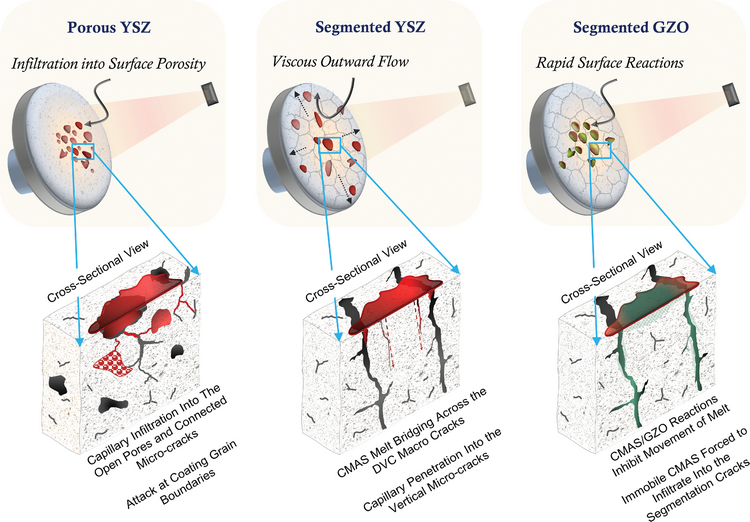

Air plasma sprayed thermal barrier coatings (TBCs) are used extensively throughout the gas turbine industry for both power and propulsion. As these engines push to higher temperatures, concern for failure from the melt infiltration of ingested siliceous debris [commonly called calcium–magnesium–alumino-silicate (CMAS)] arises, especially in aeroengines. 7 wt% yttria-stabilized zirconia is particularly prone to melt infiltration and stiffening-induced premature failure. Novel TBC materials such as gadolinium zirconate have been introduced for their infiltration-inhibiting CMAS reactions. Past academic work has utilized ideal laboratory furnace environments to study these phenomena. In this work, the influence of TBC microstructure and chemistry on impinging molten CMAS injected via a burner rig is studied. An observational study of the impacted surfaces and location-specific cross-sectional analysis is reported. Results point toward the critical role of surface microstructure on the mobility and reactivity of the molten CMAS.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 35 , Issue 17: Focus Issue: Sand-phobic Thermal/Environmental Barrier Coatings for Gas Turbine Engines , 14 September 2020 , pp. 2321 - 2334

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 9

- Cited by