Abstract

There is growing evidence for the advantages of synthesizing nanosized zeolites with markedly reduced internal diffusion limitations for enhanced performances in catalysis and adsorption. Producing zeolite crystals with sizes less than 100 nm, however, is non-trivial, often requires the use of complex organics and typically results in a small product yield. Here we present an alternative, facile approach to enhance the mass-transport properties of zeolites by the epitaxial growth of fin-like protrusions on seed crystals. We validate this generalizable methodology on two common zeolites and confirm that fins are in crystallographic registry with the underlying seeds, and that secondary growth does not impede access to the micropores. Molecular modelling and time-resolved titration experiments of finned zeolites probe internal diffusion and reveal substantial improvements in mass transport, consistent with catalytic tests of a model reaction, which show that these structures behave as pseudo-nanocrystals with sizes commensurate to that of the fin. This approach could be extended to the rational synthesis of other zeolite and aluminosilicate materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gallego, E. M. et al. ‘Ab initio’ synthesis of zeolites for preestablished catalytic reactions. Science 355, 1051–1054 (2017).

Paolucci, C. et al. Dynamic multinuclear sites formed by mobilized copper ions in NOx selective catalytic reduction. Science 357, 898–903 (2017).

Cychosz, K. A., Guillet-Nicolas, R., Garcia-Martinez, J. & Thommes, M. Recent advances in the textural characterization of hierarchically structured nanoporous materials. Chem. Soc. Rev. 46, 389–414 (2017).

Varoon, K. et al. Dispersible exfoliated zeolite nanosheets and their application as a selective membrane. Science 333, 72–75 (2011).

Rangnekar, N., Mittal, N., Elyassi, B., Caro, J. & Tsapatsis, M. Zeolite membranes—a review and comparison with MOFs. Chem. Soc. Rev. 44, 7128–7154 (2015).

Karwacki, L. et al. Morphology-dependent zeolite intergrowth structures leading to distinct internal and outer-surface molecular diffusion barriers. Nat. Mater. 8, 959–965 (2009).

Hwang, A. et al. Effects of diffusional constraints on lifetime and selectivity in methanol-to-olefins catalysis on HSAPO-34. J. Catal. 369, 122–132 (2019).

Awala, H. et al. Template-free nanosized faujasite-type zeolites. Nat. Mater. 14, 447–451 (2015).

Choi, M. et al. Stable single-unit-cell nanosheets of zeolite MFI as active and long-lived catalysts. Nature 461, 246–249 (2009).

Na, K. et al. Directing zeolite structures into hierarchically nanoporous architectures. Science 333, 328–332 (2011).

Zhang, X. et al. Synthesis of self-pillared zeolite nanosheets by repetitive branching. Science 336, 1684–1687 (2012).

Mintova, S. et al. Nanosized microporous crystals: emerging applications. Chem. Soc. Rev. 44, 7207–7233 (2015).

Gallego, E. M. et al. Simple organic structure directing agents for synthesizing nanocrystalline zeolites. Chem. Sci 8, 8138–8149 (2017).

Vicente, J. et al. Direct synthesis of nano-ferrierite along the 10-ring-channel direction boosts their catalytic behavior. Angew. Chem. Int. Ed. 57, 3459–3463 (2018).

Li, K., Valla, J. & Garcia-Martinez, J. Realizing the commercial potential of hierarchical zeolites: new opportunities in catalytic cracking. ChemCatChem 6, 46–66 (2014).

Perez-Ramirez, J., Christensen, C. H., Egeblad, K., Christensen, C. H. & Groen, J. C. Hierarchical zeolites: enhanced utilisation of microporous crystals in catalysis by advances in materials design. Chem. Soc. Rev. 37, 2530–2542 (2008).

Liu, Y. et al. Steam-stable aluminosilicate mesostructures assembled from zeolite type Y seeds. J. Am. Chem. Soc. 122, 8791–8792 (2000).

Park, D. H. et al. Selective petroleum refining over a zeolite catalyst with small intracrystal mesopores. Angew. Chem. Int. Ed. 48, 7645–7648 (2009).

Shen, Y. et al. Deconvoluting the competing effects of framework topology and diffusion path length on methanol-to-hydrocarbons reactions. ACS Catal. 8, 11042–11053 (2018).

Ristanovic, Z. et al. Intergrowth structure and aluminium zoning of a zeolite ZSM-5 crystal as resolved by synchrotron-based micro X-Ray diffraction imaging. Angew. Chem. Int. Ed. 52, 13382–13386 (2013).

Ding, K. et al. Constructing hierarchical porous zeolites via kinetic regulation. J. Am. Chem. Soc. 137, 11238–11241 (2015).

De Yoreo, J. J. et al. Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 349, aaa6760 (2015).

Lupulescu, A. I. & Rimer, J. D. In situ imaging of silicalite-1 surface growth reveals the mechanism of crystallization. Science 344, 729–732 (2014).

Zhu, H., Liu, Z., Kong, D., Wang, Y. & Xie, Z. Synthesis and catalytic performances of mesoporous zeolites templated by polyvinyl butyral gel as the mesopore directing agent. J. Phys. Chem. C 112, 17257–17264 (2008).

Zhang, H. et al. Seeding bundlelike MFI zeolite mesocrystals: A dynamic, nonclassical crystallization via epitaxially anisotropic growth. Chem. Mater. 29, 9247–9255 (2017).

Kim, S., Park, G., Woo, M. H., Kwak, G. & Kim, S. K. Control of hierarchical structure and framework–Al distribution of ZSM-5 via adjusting crystallization temperature and their effects on methanol conversion. ACS Catal. 9, 2880–2892 (2019).

Ghorbanpour, A., Gumidyala, A., Grabow, L. C., Crossley, S. P. & Rimer, J. D. Epitaxial growth of ZSM-5@silicalite-1: a core-shell zeolite designed with passivated surface acidity. ACS Nano 9, 4006–4016 (2015).

Ilias, S. & Bhan, A. Mechanism of the catalytic conversion of methanol to hydrocarbons. ACS Catal. 3, 18–31 (2013).

Khare, R., Millar, D. & Bhan, A. A mechanistic basis for the effects of crystallite size on light olefin selectivity in methanol-to-hydrocarbons conversion on MFI. J. Catal. 321, 23–31 (2015).

Nordvang, E. C., Borodina, E., Ruiz-Martinez, J., Fehrmann, R. & Weckhuysen, B. M. Effects of coke deposits on the catalytic performance of large zeolite H-ZSM-5 crystals during alcohol-to-hydrocarbon reactions as investigated by a combination of optical spectroscopy and microscopy. Chem. Eur. J. 21, 17324–17335 (2015).

Kolokathis, P. D. et al. Dimensionality reduction of free energy profiles of benzene in silicalite-1: calculation of diffusion coefficients using transition state theory. Mol. Simul. 40, 80–100 (2014).

Ruthven, D. M., Eic, M. & Richard, E. Diffusion of C8 aromatic hydrocarbons in silicalite. Zeolites 11, 647–653 (1991).

Góra-Marek, Kinga, Tarach, Karolina & Choi, Minkee 2,6-Di-tert-butylpyridine sorption approach to quantify the external acidity in hierarchical zeolites. J. Phys. Chem. C 118, 12266–12274 (2014).

Shen, Y., Le, T. T., Li, R. & Rimer, J. D. Optimized synthesis of ZSM-11 catalysts using 1,8-diaminooctane as a structure-directing agent. ChemPhysChem 19, 529–537 (2018).

International Zeolite Association (IZA) Structure Database. IZA http://www.iza-structure.org/databases/ (2017).

Borodina, E. et al. Influence of the reaction temperature on the nature of the active and deactivating species during methanol to olefins conversion over H-SSZ-13. ACS Catal. 5, 992–1003 (2015).

Yarulina, I. et al. Structure-performance descriptors and the role of Lewis acidity in the methanol-to-propylene process. Nat. Chem. 10, 804–812 (2018).

Laloué, N., Laroche, C., Jobic, H. & Methivier, A. Kinetic Monte Carlo study of binary diffusion in silicalite. Adsorption 13, 491–500 (2007).

Forester, T. R. & Smith, W. Bluemoon simulations of benzene in silicalite-1 - Prediction of free energies and diffusion coefficients. J. Chem. Soc. Faraday Trans. 93, 3249–3257 (1997).

Acknowledgements

J.D.R. acknowledges support primarily from the US Department of Energy, Office of Science, Office of Basic Energy Sciences (award DE-SC0014468). J.D.R. and J.C.P. acknowledge funding from the Welch Foundation (award nos. E-1794 and E-1882, respectively). X.Z. received funding from the Swedish Research Council (award no. 2017-0432) and the Knut and Alice Wallenberg Foundation (award no. 2012.0112). P.J.D. and M.T. received funding from the Catalysis Center for Energy Innovation, a US Department of Energy—Energy Frontier Research Center under Grant DE-SC0001004. B.M.W. acknowledges financial support from a European Research Council (ERC) Advanced Grant (no. 321140) and the Netherlands Organization for Scientific Research (NWO) Gravitation Program (Netherlands Center for Multiscale Catalytic Energy Conversion, MCEC) funded by the Ministry of Education, Culture and Science of the government of the Netherlands. J.C.P. received additional funding from the National Science Foundation (award CBET-1629398). We thank P. Kumar for assistance with XRD analysis.

Author information

Authors and Affiliations

Contributions

J.D.R. and Y.S. conceived the project and designed the experiments. H.D., T.Y., C.L., D.F., A.A. and T.T.L. were primarily responsible for the data collection and analysis. X.Z. and B.M.W. were responsible for TEM and operando UV–vis measurements, respectively. P.J.D. and M.T. were responsible for the TMPyr titration measurements. J.C.P. conducted the computational studies. J.D.R. was responsible for the zeolite synthesis, characterization and catalytic testing. J.D.R. and H.D. wrote the manuscript and prepared the figures with help from the other co-authors. All the authors contributed to the scientific discussions and preparation of the manuscript and Supplementary Information materials.

Corresponding author

Ethics declarations

Competing interests

J.D.R., Y.S. and H.D. filed a provisional patent based on the concepts developed in this manuscript.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods, Notes 1–3, Tables 1–7, Figs. 1–21, Videos 1–5 captions and references 40–59.

Supplementary Video 1

Sequence of z stacks from electron tomography of the finned MEL-F1 sample prepared by a one-pot synthesis, corresponding to Fig. 1c.

Supplementary Video 2

Sequence of z stacks from electron tomography of the MEL-finned sample prepared by seeded growth, corresponding to snapshots in Fig. 2i.

Supplementary Video 3

Sequence of z stacks from electron tomography of the MFI-finned sample prepared by seeded growth, corresponding to snapshots in Fig. 2j.

Supplementary Video 4

An SMD trajectory of TMPyr cage hopping in a straight channel of MEL (silicalite-2), viewed along the [001] direction.

Supplementary Video 5

An SMD trajectory of TMPyr cage hopping in the straight channel of MFI (silicalite-1), viewed along the [100] direction.

Source data

Source Data Fig. 1

MTH conversion and selectivity as a function of TOS for one-pot ZSM-11 catalysts.

Source Data Fig. 3

MTH conversion and selectivity as a function of TOS for seeded ZSM-11 catalysts; MTH conversion and selectivity as a function of TOS for seeded ZSM-5 catalysts; Selectivity comparisons for seeded ZSM-11 and ZSM-5 catalysts; Ethene/2MBu ratio for seeded ZSM-11 and ZSM-5 catalysts; Operando UV-vis diffuse reflectance spectroscopy for ZSM-11 and ZSM-5 catalysts; Time-on-stream methanol conversion over as-received and finned commercial H-ZSM-5 during the MTH reaction.

Source Data Fig. 4

Log probability density distribution of benzene diffusion path length r for a finned zeolite and a seed crystal; Time-resolved titration of Brønsted acid sites for H-ZSM-11 seed and finned samples; Differential plot of titrated Brønsted acid sites in Zeolyst ZSM-5 seed/finned samples and self-pillared pentasil (SPP) zeolite.

Source Data Fig. S2

Nitrogen adsorption/desorption isotherm for the finned ZSM-11 sample prepared by a one-pot synthesis.

Source Data Fig. S5

Powder X-ray diffraction patterns of as-synthesized ZSM-11 samples.

Source Data Fig. S6

Powder X-ray diffraction patterns of as-synthesized ZSM-5 samples.

Source Data Fig. S7

Nitrogen adsorption/desorption isotherms for seed and finned samples of ZSM-11 and ZSM-5 catalysts.

Source Data Fig. S8

Calculated percent increase in specific surface area for finned zeolites compared to their original seeds as a function of seed crystal size, β.

Source Data Fig. S9

Solid state 27Al NMR analysis for seed and finned samples of zeolite ZSM-11 and ZSM-5 catalysts.

Source Data Fig. S10

Product selectivities and methanol conversion as a function of TOS for seed and finned ZSM-11 and ZSM-5 catalysts.

Source Data Fig. S11

Operando UV-vis diffuse reflectance spectroscopy data within 3 min TOS for seed and finned ZSM-11 and ZSM-5 catalysts.

Source Data Fig. S13

Product selectivities and methanol conversion as a function of TOS for Zeolyst and finned Zeolyst ZSM-5 catalysts.

Source Data Fig. S15

Raw FTIR spectra of a catalyst as a function of time highlighting peaks of interest.

Source Data Fig. S16

Parity plot between loss of Brønsted acid sites and increased 2,4,6-trimethylpyridinium ions.

Source Data Fig. S17

Time-resolved titration of Brønsted acid sites for ZSM-5 seed/finned samples and Zeolyst/finned Zeolyst samples.

Source Data Fig. S18

Differential plot of titrated Brønsted acid sites in ZSM-11 seed/finned samples and H-ZSM-5 seed/finned samples.

Source Data Fig. S20

Uptake data of MEL-Seed, MFI-Seed, MEL-Finned, and MFI-Finned samples from Brønsted acid site titrations by 2,4,6-trimethylpyridine for two separate runs.

Source Data Table 1

Diffusion time constants from TMPyr titrations of ZSM-11, ZSM-5, and SPP zeolite catalysts.

Source Data Table S1

Characterization of conventional and finned ZSM-11 samples prepared by a one-pot synthesis.

Source Data Table S3

Characterization of seed and finned ZSM-11 and ZSM-5 samples prepared by seeded synthesis.

Source Data Table S5

Characterization of commercial and finned H-ZSM-5 catalysts.

Source Data Table S7

Kinetic Monte Carlo simulation results for benzene transport in silicalite-1 for seed and finned crystals with linear dimensions of α ≈ 50 nm and β ≈ 500 nm.

Rights and permissions

About this article

Cite this article

Dai, H., Shen, Y., Yang, T. et al. Finned zeolite catalysts. Nat. Mater. 19, 1074–1080 (2020). https://doi.org/10.1038/s41563-020-0753-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-020-0753-1

This article is cited by

-

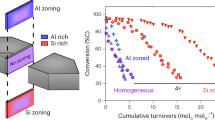

Elemental zoning enhances mass transport in zeolite catalysts for methanol to hydrocarbons

Nature Catalysis (2023)

-

Hyperloop-like diffusion of long-chain molecules under confinement

Nature Communications (2023)

-

Nonclassical mechanisms to irreversibly suppress β-hematin crystal growth

Communications Biology (2023)

-

Intra-crystalline mesoporous zeolite encapsulation-derived thermally robust metal nanocatalyst in deep oxidation of light alkanes

Nature Communications (2022)

-

Synthesis strategies and design principles for nanosized and hierarchical zeolites

Nature Synthesis (2022)