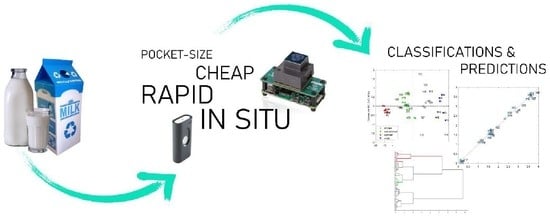

Rapid Analysis of Milk Using Low-Cost Pocket-Size NIR Spectrometers and Multivariate Analysis

Abstract

:1. Introduction

2. Instruments and Samples

2.1. Instrumentation

2.2. Samples

2.3. Statistical Data Analysis

3. Results and Discussion

3.1. Optimization of the Instrumental Setup

3.1.1. SCiO

3.1.2. NeoSpectra

3.1.3. Spectroscopic Signals

3.2. Multivariate Statistical Analysis

3.2.1. Spectral Pre-Treatment and Exploratory Data Analysis

3.2.2. Cluster Analysis

3.2.3. Prediction of Fats and Proteins

Prediction of the Fat Content

Prediction of the Protein Content

Prediction of Carbohydrates Content

3.2.4. Data Fusion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- International Dairy Federation. Annual Report 2018–2019; International Dairy Federation: Brussels, Belgium, 2019. [Google Scholar]

- Melfsen, A.; Hartung, E.; Haeussermann, A. Accuracy of in-line milk composition analysis with diffuse reflectance near-infrared spectroscopy. J. Dairy Sci. 2012, 95, 6465–6476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO. ISO 488:2008, Milk—Determination of fat content—Gerber Butyrometer; ISO: Geneve, Switzerland, 2008. [Google Scholar]

- ISO. ISO 1211:2010, Milk—Determination of fat content—Gravimetric Methode; ISO: Geneve, Switzerland, 2010. [Google Scholar]

- Di Stefano, V.; Avellone, G.; Bongiorno, D.; Cunsolo, V.; Muccilli, V.; Sforza, S.; Dossena, A.; Drahos, L.; Vékey, K. Applications of liquid chromatography-mass spectrometry for food analysis. J. Chromatogr. A 2012, 1259, 74–85. [Google Scholar] [CrossRef] [PubMed]

- González-Arrojo, A.; Soldado, A.; Vicente, F.; de la Roza-Delgado, B. Microwave-Assisted Methodology Feasibility for One-Step Extraction and Transmethylation of Fatty Acids in Milk for GC-Mass Spectrometry. Food Anal. Methods 2015, 8, 2250–2260. [Google Scholar] [CrossRef]

- Moltó-Puigmartí, C.; Castellote, A.I.; López-Sabater, M.C. Conjugated linoleic acid determination in human milk by fast-gas chromatography. Anal. Chim. Acta 2007, 602, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Araujo, P.; Nguyen, T.T.; Frøyland, L.; Wang, J.; Kang, J.X. Evaluation of a rapid method for the quantitative analysis of fatty acids in various matrices. J. Chromatogr. A 2008, 1212, 106–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luna, P.; Juárez, M.; de la Fuente, M.A. Gas chromatography and silver-ion high-performance liquid chromatography analysis of conjugated linoleic acid isomers in free fatty acid form using sulphuric acid in methanol as catalyst. J. Chromatogr. A 2008, 1204, 110–113. [Google Scholar] [CrossRef]

- Delmonte, P.; Fardin-Kia, A.R.; Kramer, J.K.G.; Mossoba, M.M.; Sidisky, L.; Tyburczy, C.; Rader, J.I. Evaluation of highly polar ionic liquid gas chromatographic column for the determination of the fatty acids in milk fat. J. Chromatogr. A 2012, 1233, 137–146. [Google Scholar] [CrossRef]

- de la Guardia, M.; Garrigues, S. Analytical Research Based on the Use of Low Cost Instrumentation. Pharm. Sci. 2019, 25, 82–84. [Google Scholar] [CrossRef]

- Nascimento, C.F.; Santos, P.M.; Pereira-Filho, E.R.; Rocha, F.R.P. Recent advances on determination of milk adulterants. Food Chem. 2017, 221, 1232–1244. [Google Scholar] [CrossRef]

- Saranwong, S.; Kawano, S. System design for non-destructive near infrared analyses of chemical components and total aerobic bacteria count of raw milk. J. Near Infrared Spectrosc. 2008, 398, 389–398. [Google Scholar] [CrossRef]

- Kawamura, S.; Kawasaki, M.; Nakatsuji, H.; Natsuga, M. Near-infrared spectroscopic sensing system for online monitoring of milk quality during milking. Sens. Instrum. Food Qual. Saf. 2007, 1, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Sun, D.W.; Pu, H.; Cheng, J.H. Quality analysis, classification, and authentication of liquid foods by near-infrared spectroscopy: A review of recent research developments. Crit. Rev. Food Sci. Nutr. 2017, 57, 1524–1538. [Google Scholar] [CrossRef] [PubMed]

- Soyeurt, H.; Dardenne, P.; Dehareng, F.; Lognay, G.; Veselko, D.; Marlier, M.; Bertozzi, C.; Mayeres, P.; Gengler, N. Estimating fatty acid content in cow milk using mid-infrared spectrometry. J. Dairy Sci. 2006, 89, 3690–3695. [Google Scholar] [CrossRef] [Green Version]

- Coppa, M.; Ferlay, A.; Leroux, C.; Jestin, M.; Chilliard, Y.; Martin, B.; Andueza, D. Prediction of milk fatty acid composition by near infrared reflectance spectroscopy. Int. Dairy J. 2010, 20, 182–189. [Google Scholar] [CrossRef]

- Coppa, M.; Revello-Chion, A.; Giaccone, D.; Ferlay, A.; Tabacco, E.; Borreani, G. Comparison of near and medium infrared spectroscopy to predict fatty acid composition on fresh and thawed milk. Food Chem. 2014, 150, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Holroyd, S.E. The use of near infrared spectroscopy on milk and milk products. J. Near Infrared Spectrosc. 2013, 21, 311–322. [Google Scholar] [CrossRef]

- Pasquini, C. Near infrared spectroscopy: A mature analytical technique with new perspectives—A review. Anal. Chim. Acta 2018, 1026, 8–36. [Google Scholar] [CrossRef]

- Béc, K.B.; Grabska, J.; Siesler, H.W.; Huck, C.W. Handheld near-infrared spectrometers: Where are we heading? NIR News 2020. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Wen, Q.; Nie, Q.; Chang, F.; Zhou, Y.; Wen, Z. Miniaturized NIR spectrometer based on novel MOEMS scanning tilted grating. Micromachines 2018, 9, 478. [Google Scholar] [CrossRef] [Green Version]

- Schuler, L.P.; Milne, J.S.; Dell, J.M.; Faraone, L. MEMS-based microspectrometer technologies for NIR and MIR wavelengths. J. Phys. D. Appl. Phys. 2009, 42, 133001. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Q. Biosensors and bioelectronics on smartphone for portable biochemical detection. Biosens. Bioelectron. 2016, 75, 273–284. [Google Scholar] [CrossRef] [PubMed]

- McGonigle, A.J.S.; Wilkes, T.C.; Pering, T.D.; Willmott, J.R.; Cook, J.M.; Mims, F.M.; Parisi, A.V. Smartphone spectrometers. Sensors (Switzerland) 2018, 18, 223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Llano Suárez, P.; Soldado, A.; González-Arrojo, A.; Vicente, F.; de la Roza-Delgado, B. Rapid on-site monitoring of fatty acid profile in raw milk using a handheld near infrared sensor. J. Food Compos. Anal. 2018, 70, 1–8. [Google Scholar] [CrossRef]

- de la Roza-Delgado, B.; Garrido-Varo, A.; Soldado, A.; González Arrojo, A.; Cuevas Valdés, M.; Maroto, F.; Pérez-Marín, D. Matching portable NIRS instruments for in situ monitoring indicators of milk composition. Food Control 2017, 76, 74–81. [Google Scholar] [CrossRef]

- Santos, P.M.; Pereira-Filho, E.R.; Rodriguez-Saona, L.E. Application of hand-held and portable infrared spectrometers in bovine milk analysis. J. Agric. Food Chem. 2013, 61, 1205–1211. [Google Scholar] [CrossRef]

- Liu, N.; Parra, H.A.; Pustjens, A.; Hettinga, K.; Mongondry, P.; van Ruth, S.M. Evaluation of portable near-infrared spectroscopy for organic milk authentication. Talanta 2018, 184, 128–135. [Google Scholar] [CrossRef]

- de Lima, G.F.; Andrade, S.A.C.; da Silva, V.H.; Honorato, F.A. Multivariate Classification of UHT Milk as to the Presence of Lactose Using Benchtop and Portable NIR Spectrometers. Food Anal. Methods 2018, 11, 2699–2706. [Google Scholar] [CrossRef]

- Limm, W.; Karunathilaka, S.R.; Yakes, B.J.; Mossoba, M.M. A portable mid-infrared spectrometer and a non-targeted chemometric approach for the rapid screening of economically motivated adulteration of milk powder. Int. Dairy J. 2018, 85, 177–183. [Google Scholar] [CrossRef]

- Wiedemair, V.; Langore, D.; Garsleitner, R.; Dillinger, K.; Huck, C. Investigations into the performance of a novel pocket-sized near-infrared spectrometer for cheese analysis. Molecules 2019, 24, 428. [Google Scholar] [CrossRef] [Green Version]

- Gorla, G.; Mestres, M.; Boqué, R.; Riu, J.; Spanu, D.; Giussani, B. ATR-MIR spectroscopy to predict commercial milk major components: A comparison between a handheld and a benchtop instrument. Chemom. Intell. Lab. Syst. 2020, 200, 103995. [Google Scholar] [CrossRef]

- The Commission of the European Communities. Council Regulation (EC) No 2597/97 of 18 December 1997 Laying Down Additional Rules on the Common Organization of the Market in Milk and Milk Products for Drinking Milk; 1997; Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A31997R2597 (accessed on 15 May 2020).

- Ferré, J.; Brown, S.D. Reduction of model complexity by orthogonalization with respect to non-relevant spectral changes. Appl. Spectrosc. 2001, 55, 708–714. [Google Scholar] [CrossRef]

- Klaas, N.; Faber, M.; Bro, R. Standard error of prediction for multiway PLS: 1. Background and a simulation study. Chemom. Intell. Lab. Syst. 2002, 61, 133–149. [Google Scholar]

- Griffiths, P.R.; De Haseth, J.A. Fourier Transform Infrared Spectrometry, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 9780471194040. [Google Scholar]

- Pügner, T.; Knobbe, J.; Grüger, H. Near-Infrared Grating Spectrometer for Mobile Phone Applications. Appl. Spectrosc. 2016, 70, 734–745. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cattaneo, T.M.P.; Cabassi, G.; Profaizer, M.; Giangiacomo, R. Contribution of light scattering to near infrared absorption in milk. J. Near Infrared Spectrosc. 2009, 17, 337–343. [Google Scholar] [CrossRef]

- Dahm, D.J. Explaining some light scattering properties of milk using representative layer theory. J. Near Infrared Spectrosc. 2013, 21, 323–339. [Google Scholar] [CrossRef]

- Bogomolov, A.; Melenteva, A.; Dahm, D.J. Fat globule size effect on visible and shortwave near infrared spectra of milk. J. Near Infrared Spectrosc. 2013, 21, 435–440. [Google Scholar] [CrossRef]

- Aernouts, B.; Polshin, E.; Lammertyn, J.; Saeys, W. Visible and near-infrared spectroscopic analysis of raw milk for cow health monitoring: Reflectance or transmittance? J. Dairy Sci. 2011, 94, 5315–5329. [Google Scholar] [CrossRef] [Green Version]

- Šašić, S.; Ozaki, Y. Band assignment of near-infrared spectra of milk by use of partial least-squares regression. Appl. Spectrosc. 2000, 54, 1327–1338. [Google Scholar] [CrossRef]

- Mandel, J.; Linnig, F.J. Study of Accuracy in Chemical Analysis Using Linear Calibration Curves. Anal. Chem. 1957, 29, 743–749. [Google Scholar] [CrossRef]

- Felipe-Sotelo, M.; Cal-Prieto, M.J.; Ferré, J.; Boqué, R.; Andrade, J.M.; Carlosena, A. Linear PLS regression to cope with interferences of major concomitants in the determination of antimony by ETAAS. J. Anal. Spectrom. 2006, 21, 61–68. [Google Scholar] [CrossRef]

- European Commission Health and Consumers Directorate-General. Guidance Document for Competent Authorities for the Control of Compliance with eu Legislation on: Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulation; 2012; Volume 1, Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/labelling_nutrition-vitamins_minerals-guidance_tolerances_1212_en.pdf (accessed on 7 May 2020).

- ASTM. ASTM E1655-17 Standard Practices for Infrared Multivariate Quantitative Analysis; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Vieira, S.M.; de Souza, L.M.; França, A.S.; Oliveira, L.S.; Neto, W.B. FTMIR-PLS as a promising method for rapid detection of adulteration by waste whey in raw milk. Dairy Sci. Technol. 2016, 96, 123–131. [Google Scholar] [CrossRef]

| SCiO (740–1070 nm) | NeoSpectra (1350–2558 nm) | ||

|---|---|---|---|

| Smoothing | RMSEC | 0.182 | 0.228 |

| RMSECV | 0.226 | 0.259 * | |

| r2 CV | 0.965 | 0.955 | |

| LVs | 5 | 2 | |

| Smoothing + SNV | RMSEC | 0.167 | 0.359 |

| RMSECV | 0.234 | 0.481 | |

| r2 CV | 0.962 | 0.847 | |

| LVs | 6 | 3 | |

| Smoothing + MSC | RMSEC | 0.156 | 0.363 |

| RMSECV | 0.223 | 0.494 | |

| r2 CV | 0.966 | 0.840 | |

| LVs | 6 | 3 | |

| Smoothing + 1st SG | RMSEC | 0.150 | 0.210 |

| RMSECV | 0.196 | 0.267 | |

| r2 CV | 0.974 | 0.952 | |

| LVs | 5 | 3 | |

| Smoothing + 2nd SG | RMSEC | 0.178 | 0.217 |

| RMSECV | 0.216 * | 0.288 | |

| r2 CV | 0.969 | 0.944 | |

| LVs | 2 | - | |

| SCiO lab | RMSEC | - | - |

| RMSECV | 0.272 | - | |

| r2 CV | 0.950 | - | |

| LVs | 4 | - |

| Lower Confidence Interval | Upper Confidence Interval | |||

|---|---|---|---|---|

| SCiO | 0.057 | 0.078 | −0.101 | 0.215 |

| NeoSpectra | 0.068 | 0.064 | −0.062 | 0.198 |

| SCiO (2 Factors) | NeoSpectra (2 Factors) | ||

|---|---|---|---|

| Training set | RMSEC | 0.178 | 0.228 |

| r2 CALIBRATION | 0.978 | 0.965 | |

| RMSECV | 0.216 | 0.259 | |

| r2 CV | 0.969 | 0.955 | |

| Test set | RMSEP | 0.176 | 0.287 |

| r2 PREDICTION | 0.981 | 0.980 |

| No Lactose | With Lactose | |

|---|---|---|

| Sensitivity (calibration) | 1.0 | 0.9 |

| Specificity (calibration) | 0.9 | 1.0 |

| Sensitivity (cross-validation) | 1.0 | 0.9 |

| Specificity (cross-validation) | 0.9 | 1.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riu, J.; Gorla, G.; Chakif, D.; Boqué, R.; Giussani, B. Rapid Analysis of Milk Using Low-Cost Pocket-Size NIR Spectrometers and Multivariate Analysis. Foods 2020, 9, 1090. https://doi.org/10.3390/foods9081090

Riu J, Gorla G, Chakif D, Boqué R, Giussani B. Rapid Analysis of Milk Using Low-Cost Pocket-Size NIR Spectrometers and Multivariate Analysis. Foods. 2020; 9(8):1090. https://doi.org/10.3390/foods9081090

Chicago/Turabian StyleRiu, Jordi, Giulia Gorla, Dib Chakif, Ricard Boqué, and Barbara Giussani. 2020. "Rapid Analysis of Milk Using Low-Cost Pocket-Size NIR Spectrometers and Multivariate Analysis" Foods 9, no. 8: 1090. https://doi.org/10.3390/foods9081090