Abstract

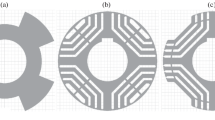

This article is devoted to development of synthesis of power drive system of KhPT-250 cold rolling mill. Selection procedures for process variables of the reducer, electric machine, and power circuits have been developed. It has been noted that the configuration of power circuits can decrease failures by about 30%. It has been demonstrated that, in the power drives of the KhPT-250 mill, it is required to take pipe deformability into account and the control object should be considered as a multicircuit double-mass system. It is proposed to select the gear reduction rate on the basis of the criterion of minimum oscillation. With this aim in mind, the methods of frequency synthesis have been applied to construct asymptotic frequency characteristics used for determination of the reducing gear factor in the case of a restricted amplitude of the resonance maximum. Using the finite element method, the geometrical parameters of the stator and rotor of a synchronous reluctance machine have been selected, and its weight and dimensions have been improved by about 35%. Predictions demonstrate that the best ratio of the flow longitudinal constituent to the transversal constituent is obtained for a axially laminated rotor. Implementation of a power drive system with a field regulated synchronous reluctance motor on a KhPT-250 cold rolling mill made it possible to increase the mill output by 10–15%, with the quality of rolled products improving by 20–25%. According to preliminary estimations, the annual efficiency of the power drive system will be from 2 to 5 million rubles.

Similar content being viewed by others

REFERENCES

Belykh, I.A. and Grigorev, M.A., The pipe rotation electric drive of a cold rolling mill at JSC Chelyabinsk pipe plant, Russ. Electr. Eng., 2019, vol. 90, no. 5.

Usynin, Yu.S., Sistemy upravleniya elektroprivodov (The Control Systems of Electric Drives), Chelyabinsk: Yuzh.-Ural. Gos. Univ., 2004.

Feofilov, S.V., Intermittent movements in digitally controlled relay systems, Mekhatron., Avtom., Upr., 2006, no. 11.

Zhuravlev, A.M., The reliability of semiconductor converters and electric drives in oxygen-converter production facilities, Cand. Sci. (Eng.) Dissertation, Chelyabinsk: South Ural State Univ., 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Moshkin

About this article

Cite this article

Korzhavin, M.E., Chupin, E.S. & Grigor’ev, M.A. A Power Drive System for Pipe Rotation and Delivery Mechanisms of a KhPT-250 Cold Rolling Mill. Russ. Electr. Engin. 91, 298–301 (2020). https://doi.org/10.3103/S1068371220050065

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068371220050065