Abstract

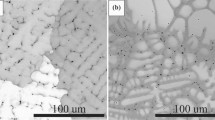

In the present work, microstructure and mechanical properties of Zn–7Al–3Cu (wt%) ternary alloy are investigated depending on the temperature gradient and growth velocity. The alloy was prepared in the designated composition in a vacuum melting and casting furnace and then filled into the graphite sample moulds. The samples were directional solidified with various temperature gradients (6.7–10.7 K/mm) at a constant growth velocity (16.4 μm/s) and with various growth velocities (8.3–166.0 μm/s) at a constant temperature gradient (10.7 K/mm) in a Bridgman-type furnace. Microstructural images of solidified samples were taken with light microscope and scanning electron microscope. Eutectic spacings were measured from these images. Microhardness, ultimate tensile strength, yield strength and modulus elasticity values of each sample produced at various solidification parameters were also measured. The effect of temperature gradient and growth velocity on the eutectic spacing, microhardness, ultimate tensile strength, yield strength and modulus elasticity was determined using linear regression analysis. While the microhardness, ultimate tensile strength, yield strength and modulus elasticity values increased with increasing temperature gradient and growth velocity values or decreasing eutectic spacing, the elongation values decreased. Fractographic results show that the type of fracture is brittle.

Similar content being viewed by others

References

G. Lin, R. Zhang, L. Wang, Y. Lei, J. He, Effects of stabilizing heat treatment on microstructures and creep behavior of Zn–10Al–2Cu–0.02Ti alloy. Trans. Nonferrous Met. Soc. China 23(1), 86–91 (2013)

M. Aydın, T. Savaşkan, Fatigue properties of zinc–aluminium alloys in 3.5% NaCl and 1% HCl solutions. Int. J. Fatig. 26(1), 103–110 (2004)

H. Li, Z. Li, Y. Liu, H. Jiang, Effect of zirconium on the microstructure and mechanical properties of Zn–4%Al hypoeutectic alloy. J. Alloys Compd. 592, 127–134 (2014)

T. Savaşkan, G. Pürçek, S. Murphy, Sliding wear of cast zinc-based alloy bearings under static and dynamic loading conditions. Wear 252(9–10), 693–703 (2002)

E.M. da Costa, C.E. da Costa, F.D. Vecchia, C. Rick, M. Scherer, C.A. dos Santos, B.A. Dedavid, Study of the influence of copper and magnesium additions on the microstructure formation of Zn–Al hypoeutectic alloys. J. Alloys Compd. 488, 89–99 (2009)

F. Wang, B. Xiong, Y. Zhang, H. Liu, Z. Li, X. Li, C. Qu, Effect of Cu addition on microstructure and corrosion behavior of spray-deposited Zn–30Al alloy. Mater. Sci. Eng. A 532, 100–105 (2012)

P. Choudhury, K. Das, S. Das, Evolution of as-cast and heat-treated microstructure of a commercial bearing alloy. Mater. Sci. Eng. A 398, 332–343 (2005)

M. Al-Maharbi, I. Karaman, G. Pürçek, Flow response of a severe plastically deformed two-phase zinc-aluminum alloy. Mater. Sci. Eng. A 527, 518–525 (2010)

B.K. Prasad, Microstructural alterations through heat treatment and its influence on wear response of a silicon containing zinc based alloy under different test conditions. Mater. Sci. Technol. 19(3), 327–335 (2003)

V. Reveko, F. Lampert, G. Winther, P. Møller, Change of the decorative properties of zinc-plated zinc die castings over time. Int. J. Metalcast. 13, 130–136 (2019). https://doi.org/10.1007/s40962-018-0237-0

T. Savaşkan, A.P. Hekimoğlu, Microstructure and mechanical properties of Zn–15Al-based ternary and quaternary alloys. Mater. Sci. Eng. A 603, 52–57 (2014)

B. Krupinska, L. Dobrzanski, Z. Rdzawski, K. Labisz, Cooling rate influence on microstructure of the Zn–Al cast alloy. Arch. Mater. Sci. Eng. 43(1), 13–20 (2010)

M. Durman, S. Murphy, Precipitation of metastable ephsilon phase in a hypereutectic zinc-aluminium alloy containing copper. Acta Metall. 39(10), 2235–2242 (1991)

M. Durman, S. Murphy, An electron-metallographic study of commercial zinc-based pressure diecasting alloy ZA–27. J. Mater. Sci. 32, 1603–1611 (1997)

S. Alibabaie, R. Mahmudi, Microstructure and creep characteristics of Zn–3Cu–xAl ultra high-temperature lead-free solders. Mater. Des. 39, 397–403 (2012)

F. Porter, Zinc Handbook: Properties, and Use in Design (Dekker, New York, 1991)

T.J. Chen, Y. Hao, J. Sun, Y.D. Li, Effects of Mg and RE additions on the semi-solid microstructure of a zinc alloy ZA27. Sci. Technol. Adv. Mater. 4, 495–502 (2003)

A. Türk, M. Durman, E.S. Kayalı, The effect of manganese on the microstructure and mechanical properties of zinc–aluminium based ZA–8 alloy. J. Mater. Sci. 42, 8298–8305 (2007)

E.D. Jareno, M.J. Castro, S.I. Maldonado, F.A. Hernandez, The effects of Cu and cooling rate on the fraction and distribution of epsilon phase in Zn–4Al–(3–5.6)Cu alloys. J. Alloys Compd. 490, 524–530 (2010)

R. Mojaver, H.R. Shahverdi, Relationship between cooling rate, microstructure features and wear behavior in end-chill cast Zn–27% Al alloys containing more than 2% Cu. Wear 271(11–12), 2899–2908 (2011)

B.K. Prasad, Effects of partially substituting copper by silicon on the physical, mechanical, and wear properties of a Zn–37.5%Al based alloy. Mater. Charact. 44(3), 301–308 (2000)

B.K. Prasad, Microstructure, mechanical properties and sliding wear characteristics of Zn-based alloys: effects of partially substituting Cu by Si. Metallkd. Z 88, 929–933 (1997)

D. Yousefi, R. Taghiabadi, M.H. Shaeri, P. Abedinzadeh, Enhancing the mechanical properties of Si particle reinforced ZA22 composite by Ti–B modification. Int. J. Metalcast. (2020). https://doi.org/10.1007/s40962-020-00447-w

K. Kubota, T. Sato, R. Ninomiya, T. Ojiro, Solidification structure and strength of Zn–7Al–X Cu alloys. Imono (J. Jpn. Foundrym. Soc.) 67(8), 546–551 (1995)

S. Engin, U. Böyük, H. Kaya, N. Maraşlı, Directional solidification and physical properties measurements of the zinc-aluminum eutectic alloy. Int. J. Min. Met. Mater. 14(2), 659–664 (2011)

H. Kaya, U. Böyük, S. Engin, E. Çadırlı, N. Maraşlı, Measurements of microhardness and thermal and electrical properties of the binary Zn–0.7 wt%Cu hypoperitectic alloy. J. Electron. Mater. 39(3), 303–311 (2010). https://doi.org/10.1007/s11664-009-1061-3

Y.H. Zhu, W.B. Lee, S. To, Tensile deformation-induced phase transformation in cast Zn–Al-based alloy (ZnAl7Cu3). Mater. Res. Bull. 38(14), 1851–1858 (2003)

G. Petzow, G. Effenberg, Ternary Alloys, A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams (Weinheim Press, New York, 1988)

A. Ourdjini, J. Liu, R. Elliott, Eutectic spacing selection in the Al–Cu system. Mater. Sci. Technol. 10(4), 312–318 (1994)

J. Fan, X. Li, Y. Su, J. Guo, H. Fu, The microstructure parameters and microhardness of directionally solidified Ti–43Al–3Si alloy. J. Alloys Compd. 506, 593–599 (2010)

U. Böyük, N. Maraşlı, The microstructure parameters and microhardness of directionally solidified Sn–Ag–Cu eutectic alloy. J. Alloys Compd. 485, 264–269 (2009)

U. Böyük, N. Maraşlı, E. Çadırlı, H. Kaya, K. Keşlioğlu, Variations of microhardness with solidification parameters and electrical resistivity with temperature for Al–Cu–Ag eutectic alloy. Curr. Appl. Phys. 12(1), 7–10 (2012). https://doi.org/10.1016/j.cap.2011.0

J. Fan, X. Li, Y. Su, R. Chen, J. Gou, H. Fu, Dependency of microstructure parameters and microhardness on the temperature gradient for directionally solidified Ti–49Al alloy. Mater. Chem. Phys. 130(3), 1232–1238 (2011)

E. Çadırlı, U. Böyük, H. Kaya, N. Maraşlı, Determination of mechanical, electrical and thermal properties of the Sn–Bi–Zn ternary alloy. J. Non-Cryst. Solids 357(15), 2876–2881 (2011). https://doi.org/10.1016/j.jnoncrysol.2011.03.025

X. Hu, K. Li, F. Ai, Research on lamellar structure and micro-hardness of directionally solidified Sn–58Bi eutectic alloy. China Foundry 9(4), 360–365 (2012)

F. Vnuk, M. Sahoo, D. Baragar, R.W. Smith, Mechanical properties of the Sn–Zn eutectic alloys. J. Mater. Sci. 15(10), 2573–2583 (1980)

M. Şahin, T. Şensoy, E. Çadırlı, Microstructural evolution and mechanical properties of Sn–Bi–Cu ternary eutectic alloy produced by directional solidification. Mater. Res. 21(2), e20170901 (2018). https://doi.org/10.1590/1980-5373-mr-2017-0901

J. Lapin, L. Ondrúš, M. Nazmy, Directional solidification of intermetallic Ti–46Al–2W–0.5Si alloy in alumina moulds. Intermetallics 10(10), 1019–1031 (2002)

J. Fan, X. Li, Y. Su, J. Guo, H. Fu, Dependency of microhardness on solidification processing parameters and microstructure characteristics in the directionally solidified Ti–46Al–0.5W–0.5Si alloy. J. Alloys Compd. 504(1), 60–64 (2010)

X. Hu, Y. Li, Y. Liu, Z. Min, Developments of high strength Bi-containing Sn0.7Cu lead-free solder alloys prepared by directional solidification. J. Alloys Compd. 625, 241–250 (2015)

T. Hosch, R.E. Napolitano, The effect of the flake to fiber transition in silicon morphology on the tensile properties of Al-Si eutectic alloys. Mater. Sci. Eng. A. 528(1), 226–232 (2010)

E. Çadırlı, M. Sahin, Y. Turgut, Characterization of a directionally solidified Sn–Pb–Sb ternary eutectic alloy. Metallogr. Microstruct. Anal. 4(4), 286–297 (2015). https://doi.org/10.1007/s13632-015-0211-7

Z.Q. Li, X.R. Zhang, S.Y. Zhang, Z.H. Shen, Determination of the elastic constants of metal-matrix composites by a laser ultrasound technique. Compos. Sci. Technol. 61(10), 1457–1463 (2001)

Acknowledgements

This project was supported by the Niğde Ömer Halisdemir University, Scientific Research Project Unit Contract No: FEB 2011/08. The authors are grateful to Niğde Ömer Halisdemir University Scientific Research Project Unit for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yılmazer, İ., Çadırlı, E. Effect of Temperature Gradient and Growth Velocity on Microstructure and Mechanical Properties on Zn–7Al–3Cu Ternary Eutectic Alloy. Inter Metalcast 15, 664–675 (2021). https://doi.org/10.1007/s40962-020-00500-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00500-8